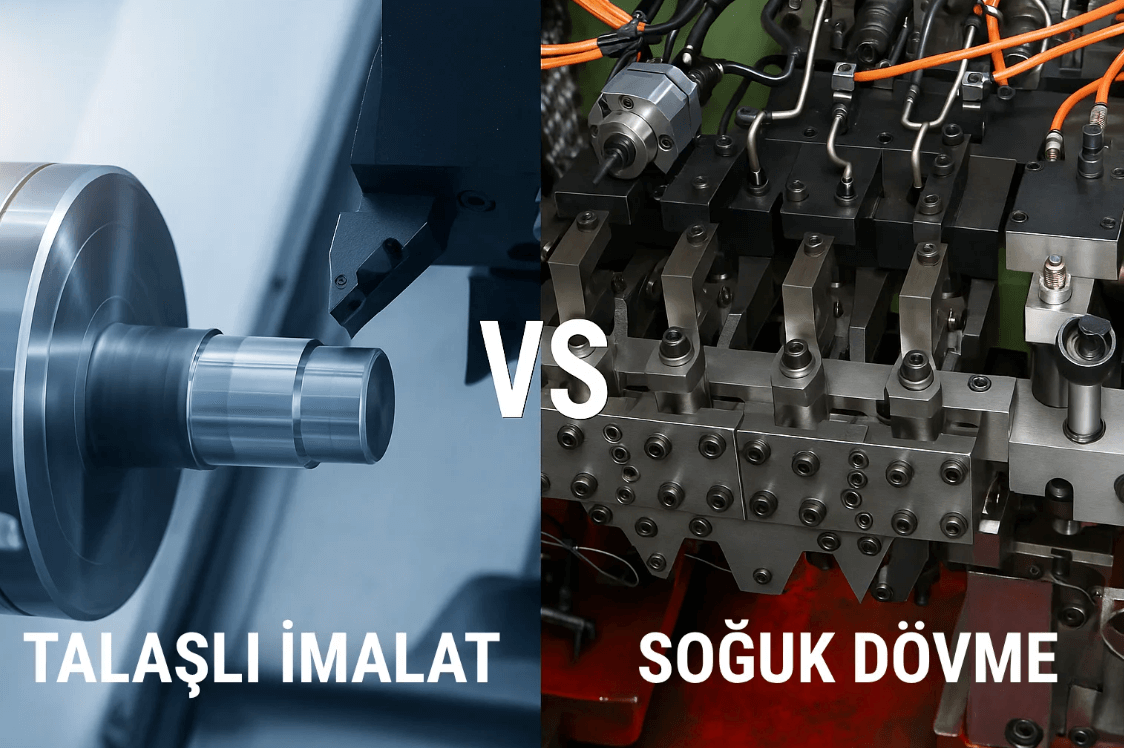

Difference Between Cold Forming and Machining

Which production method suits your need best?

In industrial production, selecting the right method determines cost, quality, and time. In this article, we compare two essential methods for mechanical parts: Cold Forming and Machining.

🧱 Key Technical Comparison

|

Feature |

Cold Forming |

Machining |

|

Process Definition |

Plastic deformation at near room temperature |

Cutting away excess material |

|

Material Usage |

Near-zero waste, highly efficient |

High material loss, especially on complex shapes |

|

Production Speed |

Very fast, suitable for high-volume production |

Slower, depends on geometry |

|

Surface Quality |

High, often no post-processing needed |

Adjustable, can reach very high quality |

|

Mechanical Properties |

Stronger, refined grain structure |

May require heat treatment to strengthen |

|

Precision |

Moderate, improved by precise tooling |

Very high, micron-level tolerances achievable |

|

Complex Shapes |

Best for simple and symmetrical parts |

Ideal for complex and multi-surface geometries |

|

Tooling Cost |

High initial investment (tooling needed) |

Lower cost, flexible tooling |

|

Part Strength |

High, fiber structure remains intact |

Lower, cutting interrupts material continuity |

|

Application Areas |

Bolts, shafts, fasteners |

Prototypes, custom machine components |

📊 When to Choose Which?

|

Requirement |

Recommended Method |

|

Mass production, cost focus |

Cold Forming |

|

Complex design |

Machining |

|

High strength requirement |

Cold Forming |

|

Tight tolerances |

Machining |

📄 Conclusion

Cold Forming: High strength, minimal waste, fast production

Machining: High precision, flexible shapes, ideal for special parts