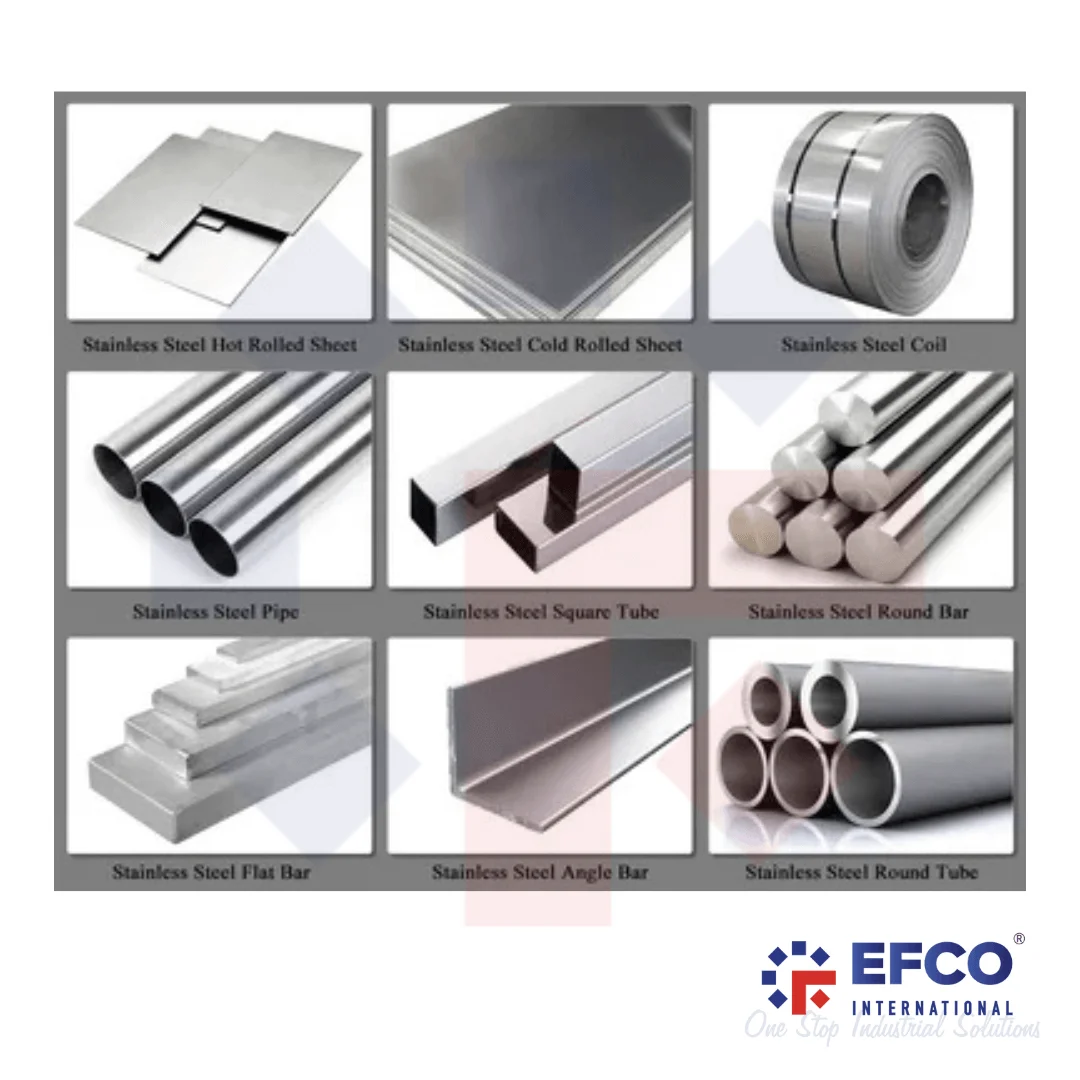

Stainless Steel Product Manufacturing and Surface Treatment

Stainless steel is preferred across many industries for its corrosion resistance and aesthetic appearance. EFCO delivers high hygiene and quality standards through the manufacturing of stainless-steel products and surface treatments.

Stainless Steel Processes

-

Cutting (press/laser/shear/plasma)

-

Bending (press brake/roll/press)

-

Welding (TIG/MIG/MAG)

-

Forming (press)

-

Surface treatment (electropolishing/mechanical polishing/sandblasting/vibratory finishing)

Scroll to the bottom for more details.

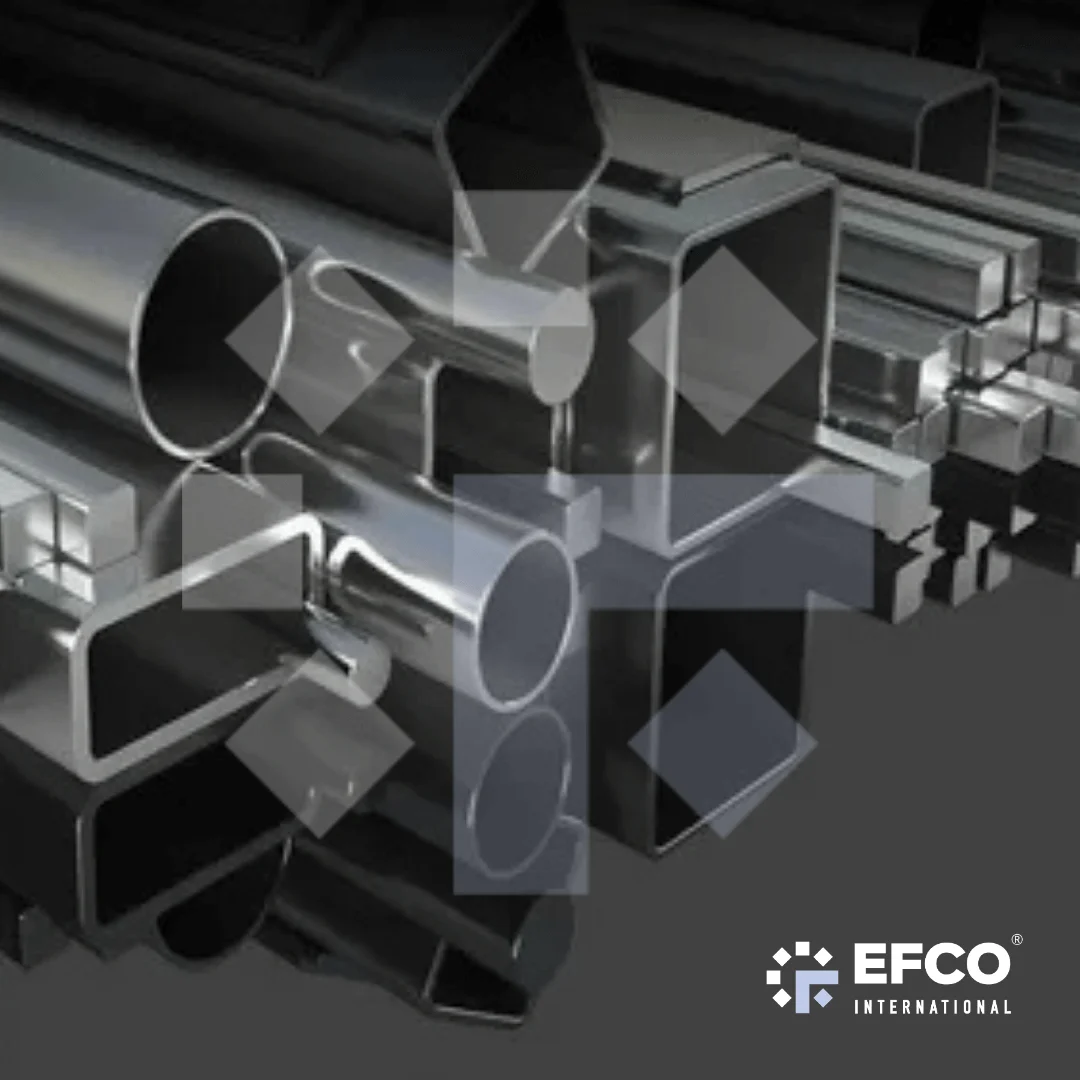

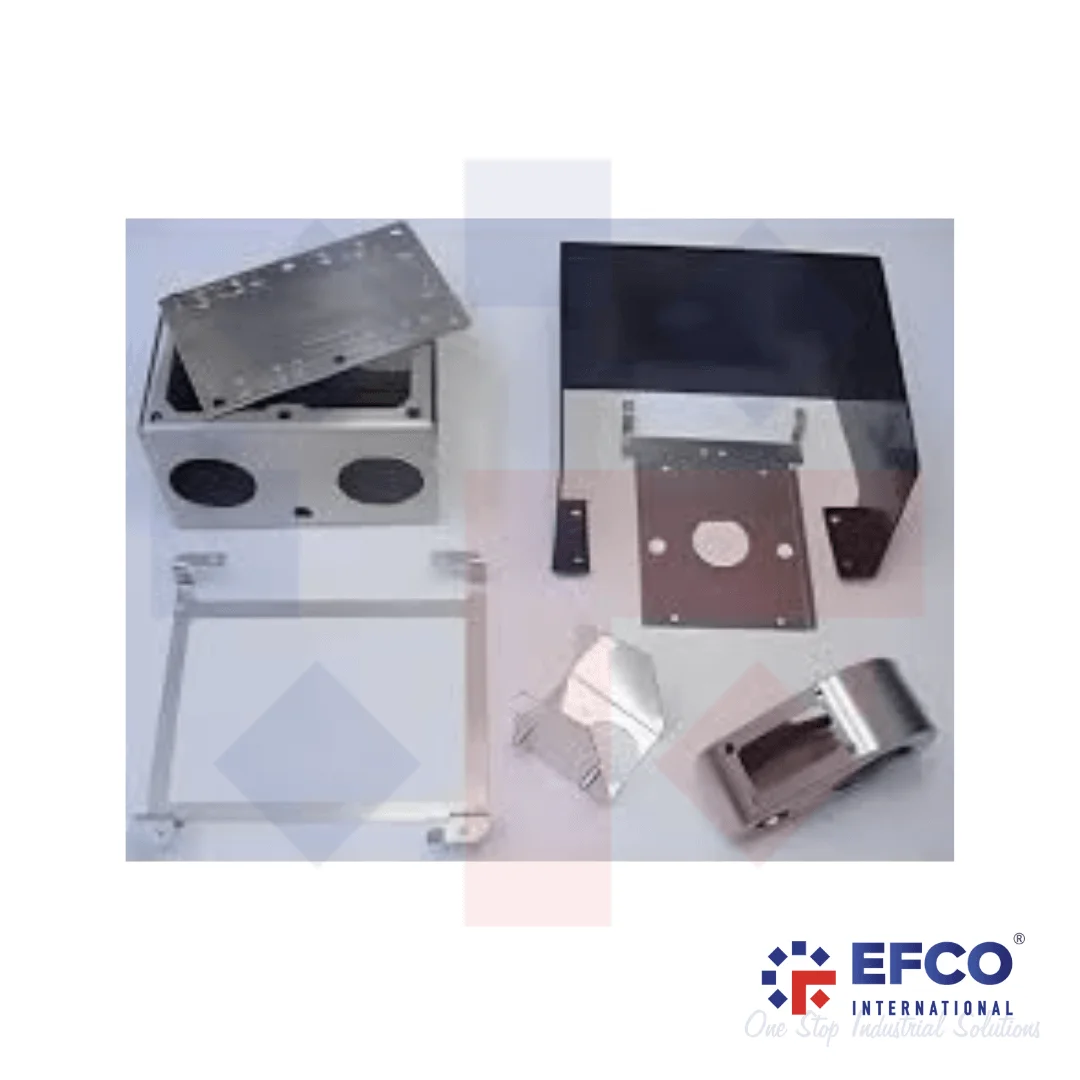

Cutting (press/laser/shear/plasma)

Dimensional cutting of stainless steel sheets and profiles.

Materials Used: 304/304L, 316/316L, 430, duplex

Specifications and Tolerances:

-

Standards: ISO 9013

-

Dimensional tolerance: ±0.1 – 0.5 mm

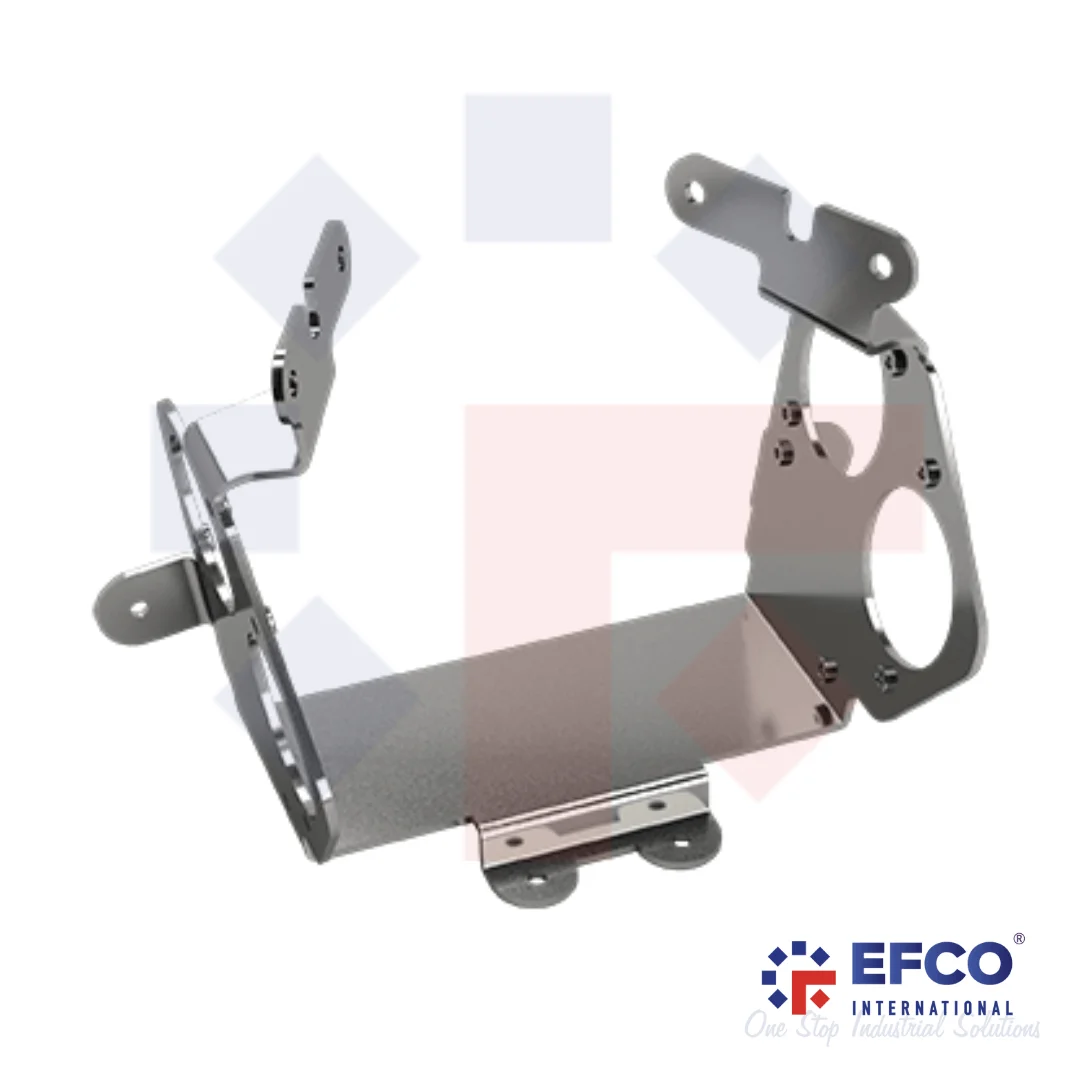

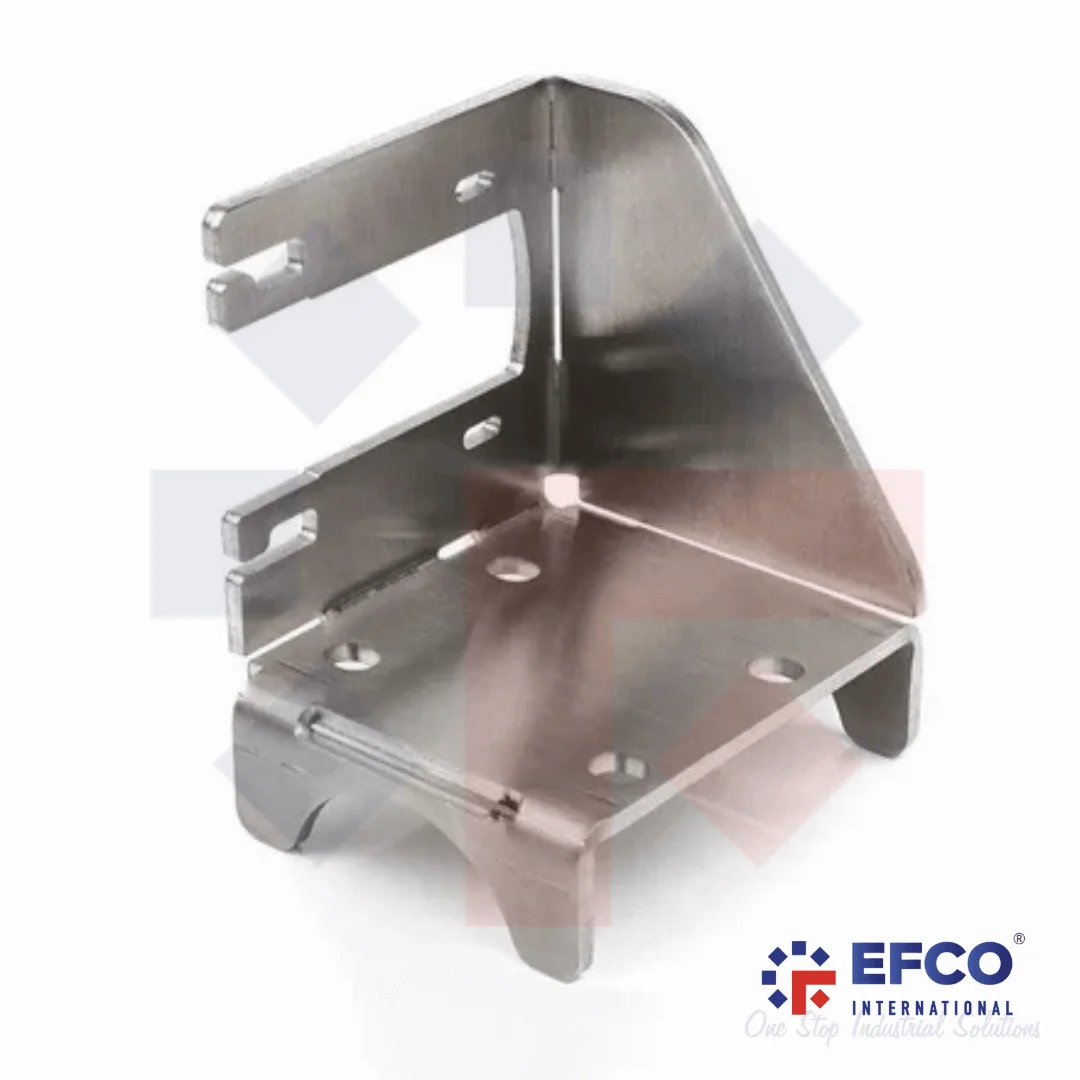

Bending (press brake/roll/press)

Bending is carried out by considering springback in stainless steel.

Materials Used: Austenitic and ferritic stainless sheets

Specifications and Tolerances:

-

Standards: ISO 2768

-

Tolerance/Angle: ±0.5 – 1.0 mm / ±0.5° – 1°

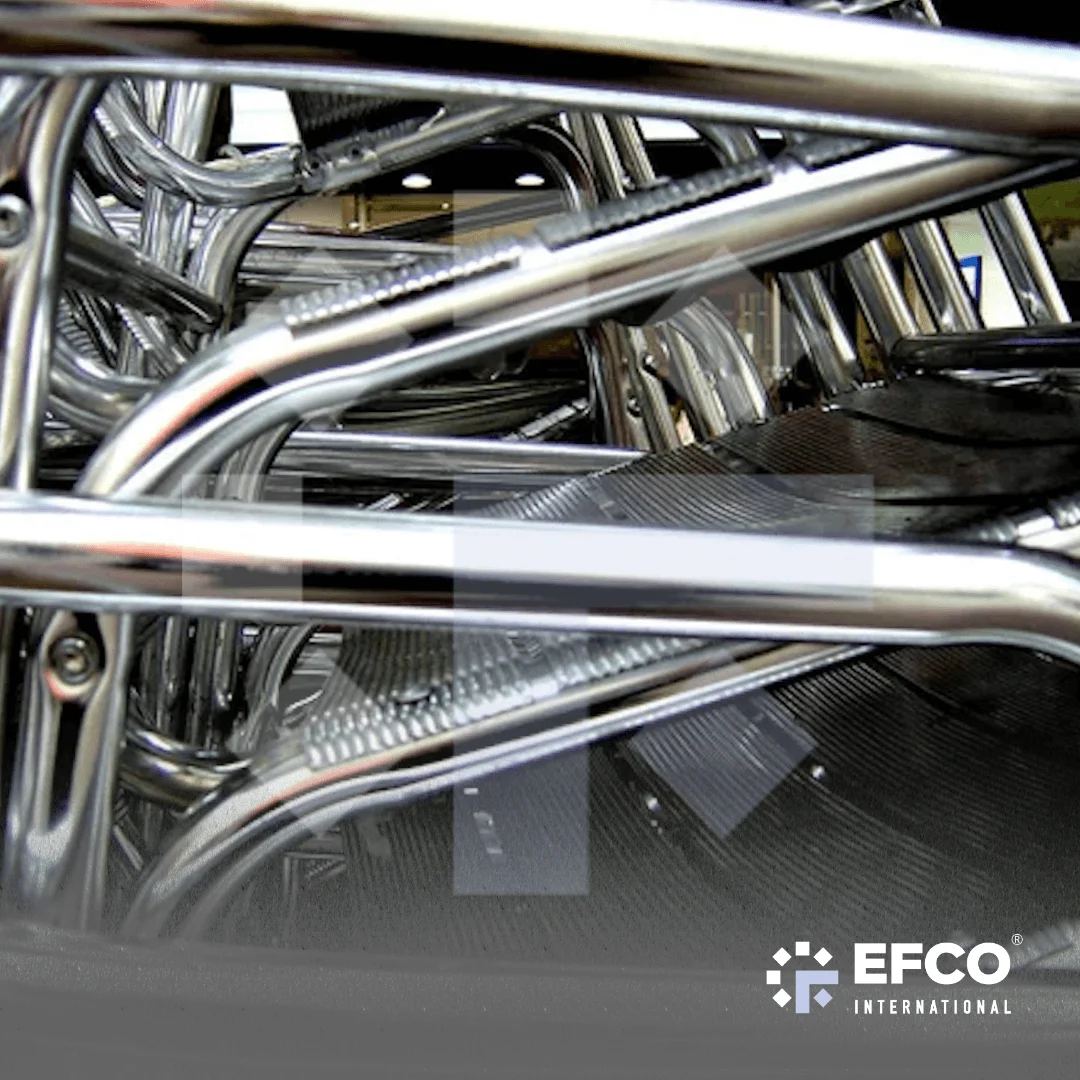

Welding (TIG/MIG)

Post-weld cleaning and passivation improve corrosion resistance.

Materials Used: 304L/316L, 2205 duplex

Specifications and Tolerances:

-

Standards: ISO 5817, ISO 9606-1

-

Tests: VT, PT; UT/RT upon request

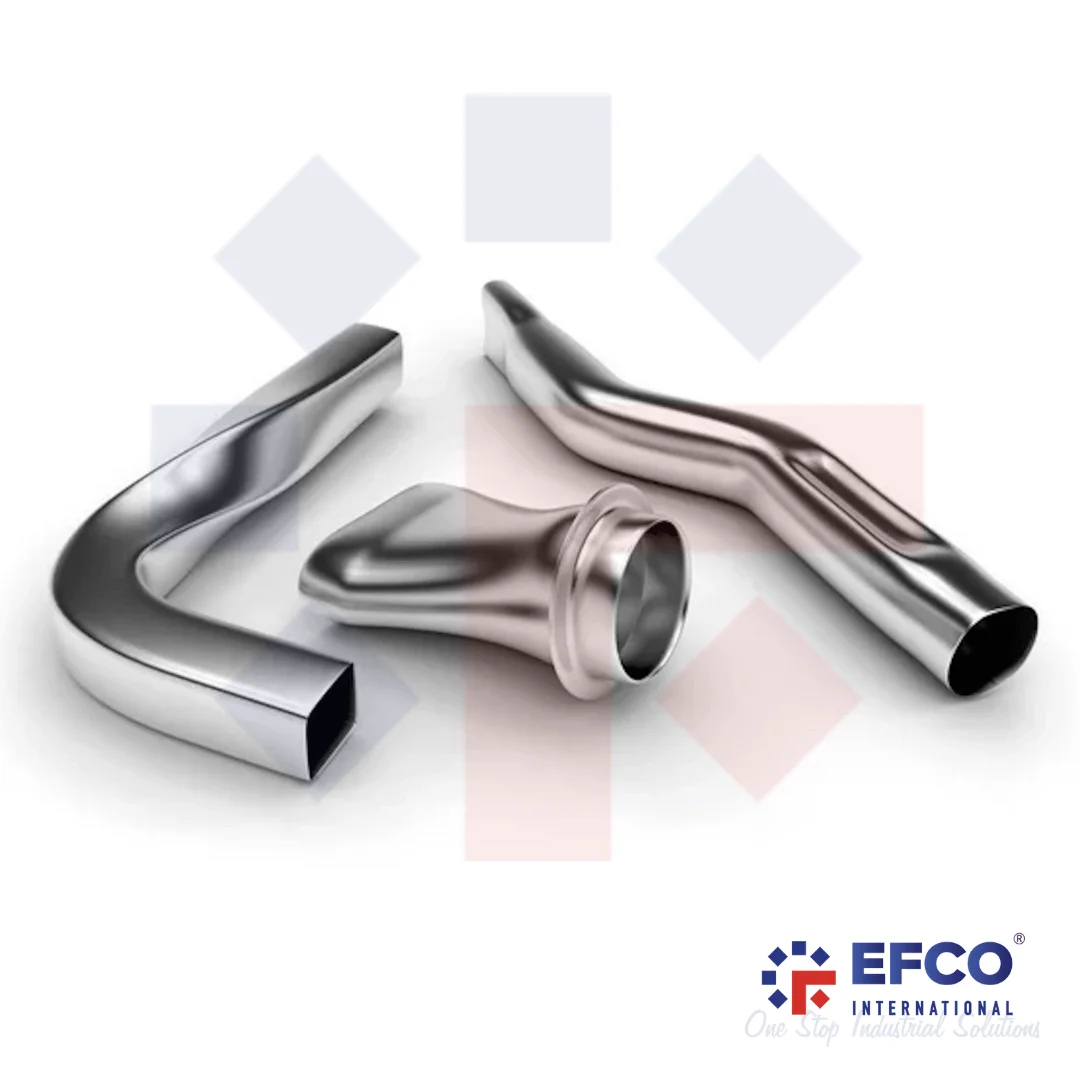

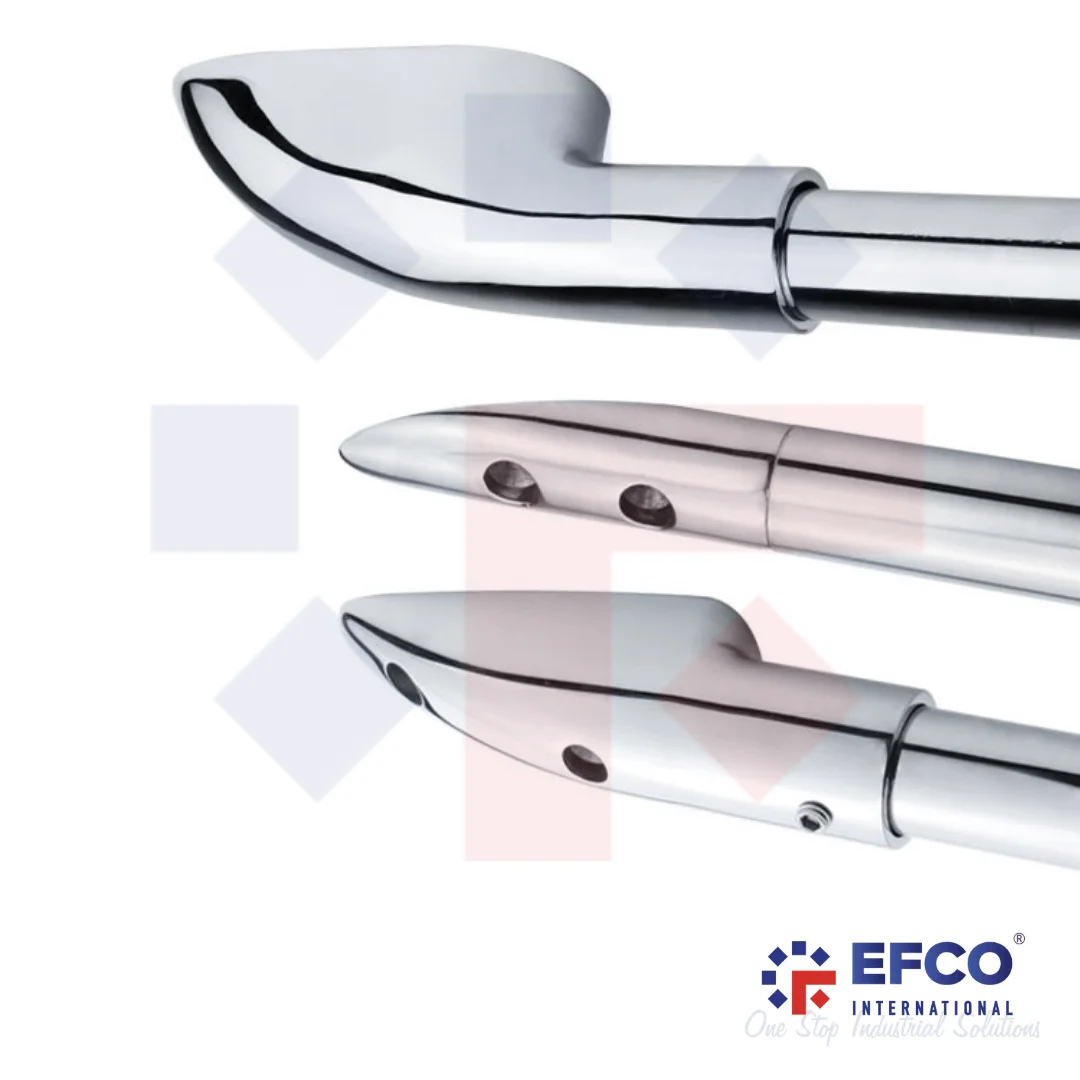

Forming (press)

Deep drawing and embossing can be performed on thin stainless steel sheets.

Materials Used: 304, 316 stainless steel

Specifications and Tolerances:

-

Standards: EN 10088

-

Dimensional tolerance: ±0.3 – 0.6 mm

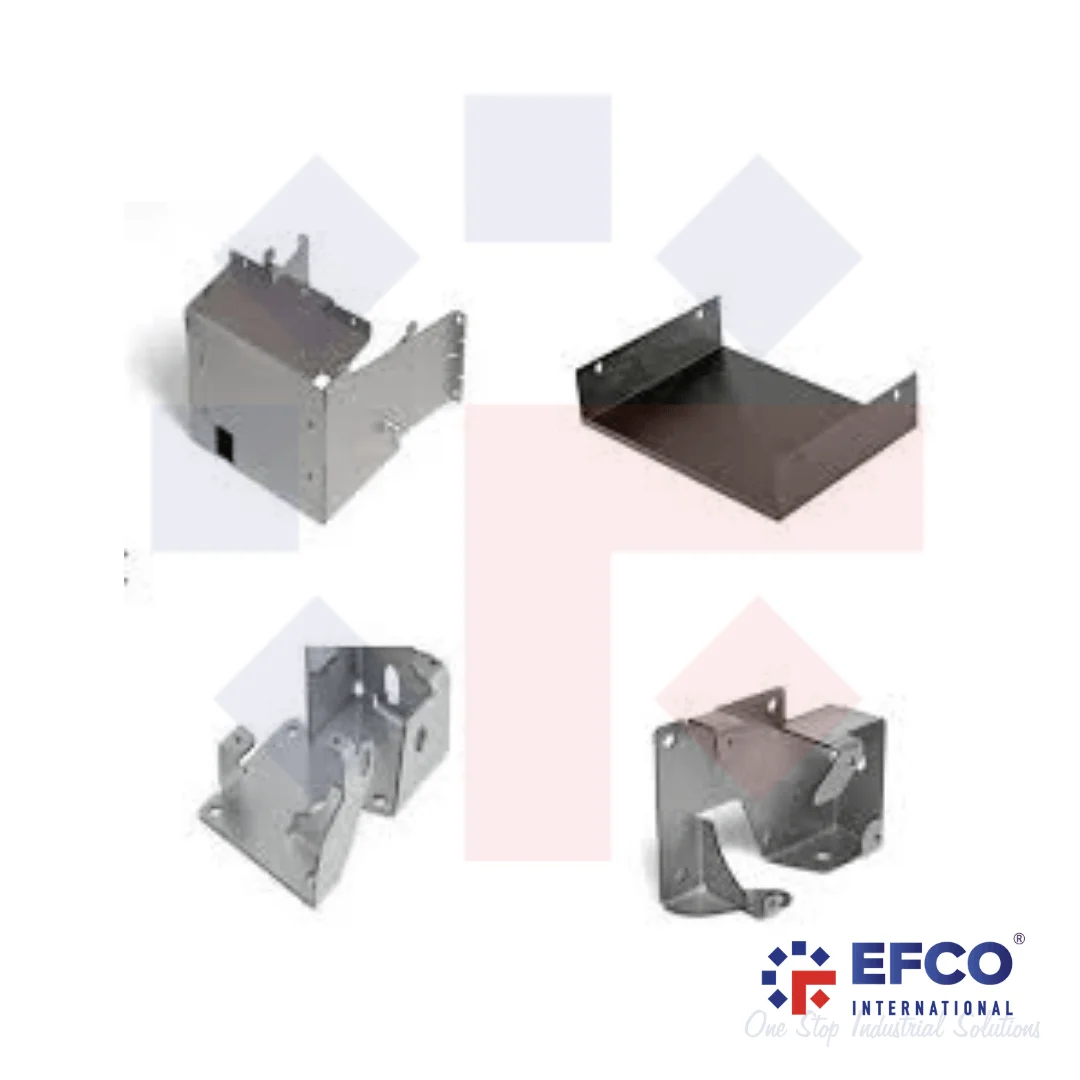

Surface Treatment (electropolishing/mechanical polishing/sandblasting)

Surface smoothing and polishing processes applied for corrosion resistance and aesthetics.

Materials Used: Stainless steel products

Specifications and Tolerances:

-

Standards: ASTM A967, EN 10088

-

Surface: Ra 0.2 – 0.8 µm

EFCO’s Contribution

-

Determines the most suitable production method and material for the project.

-

Provides certified solutions in compliance with international standards.

-

Ensures quality assurance with dimensional measurement reports and NDT tests.

-

Offers turnkey solutions with advantages in delivery time and cost.

We are always ready to help you and answer your questions!