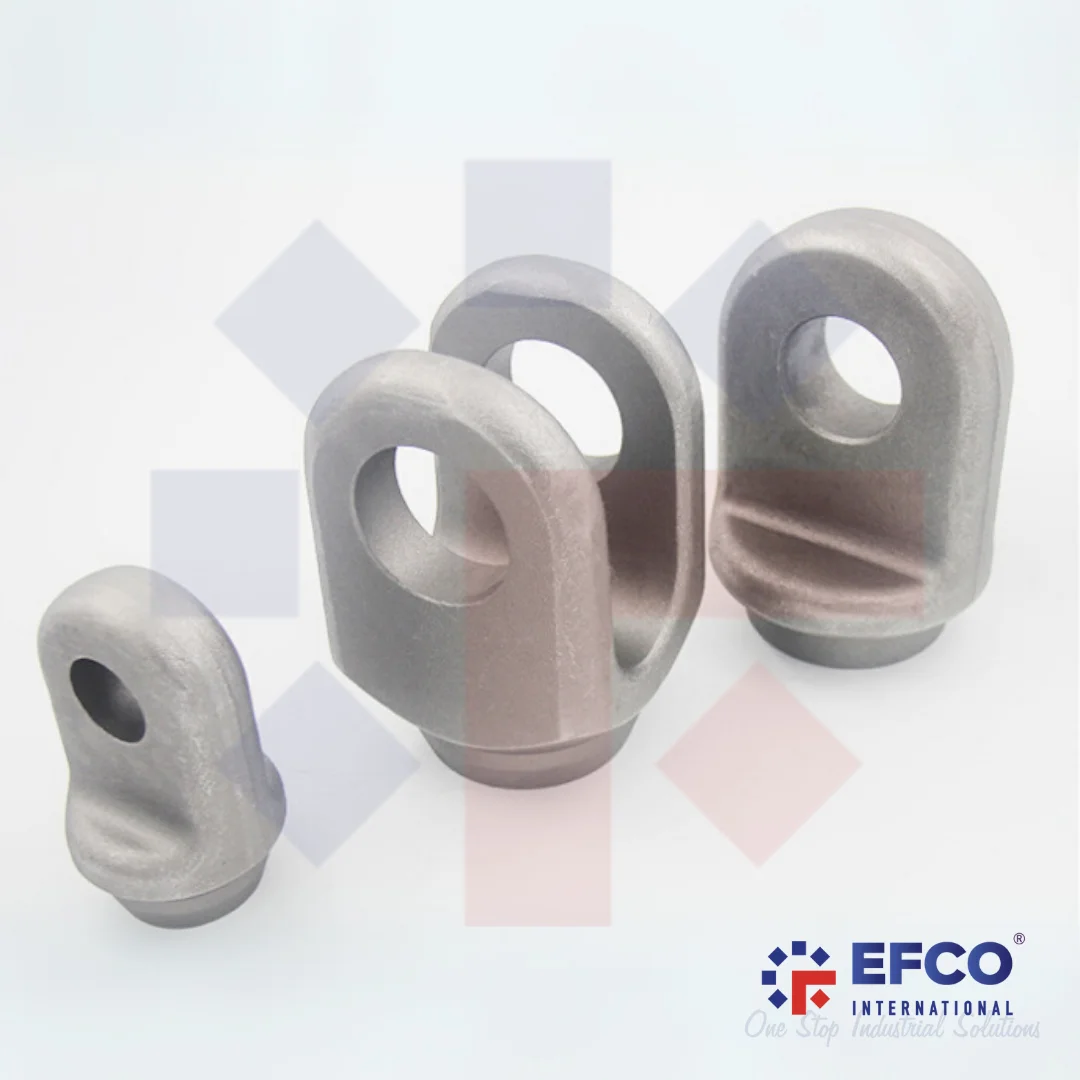

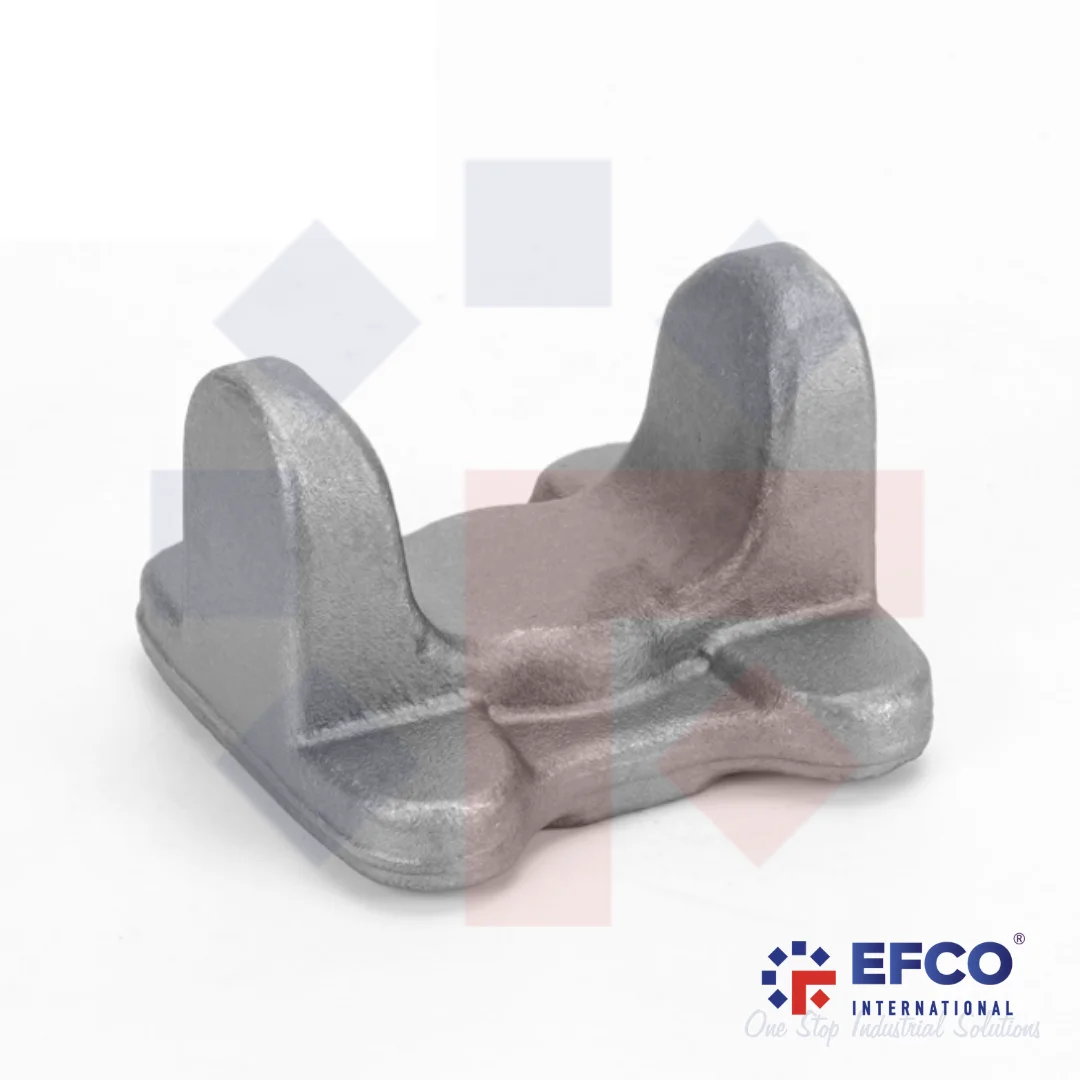

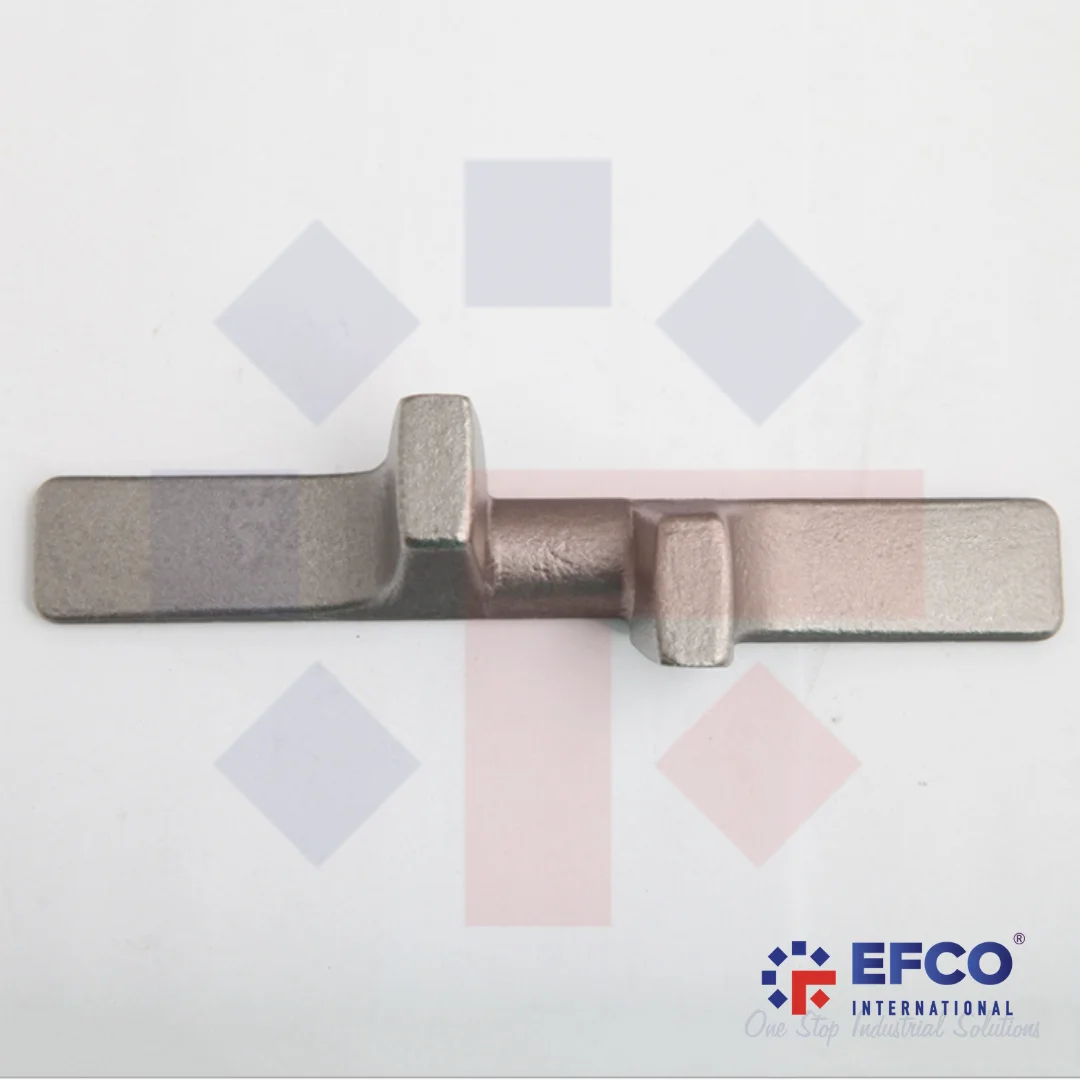

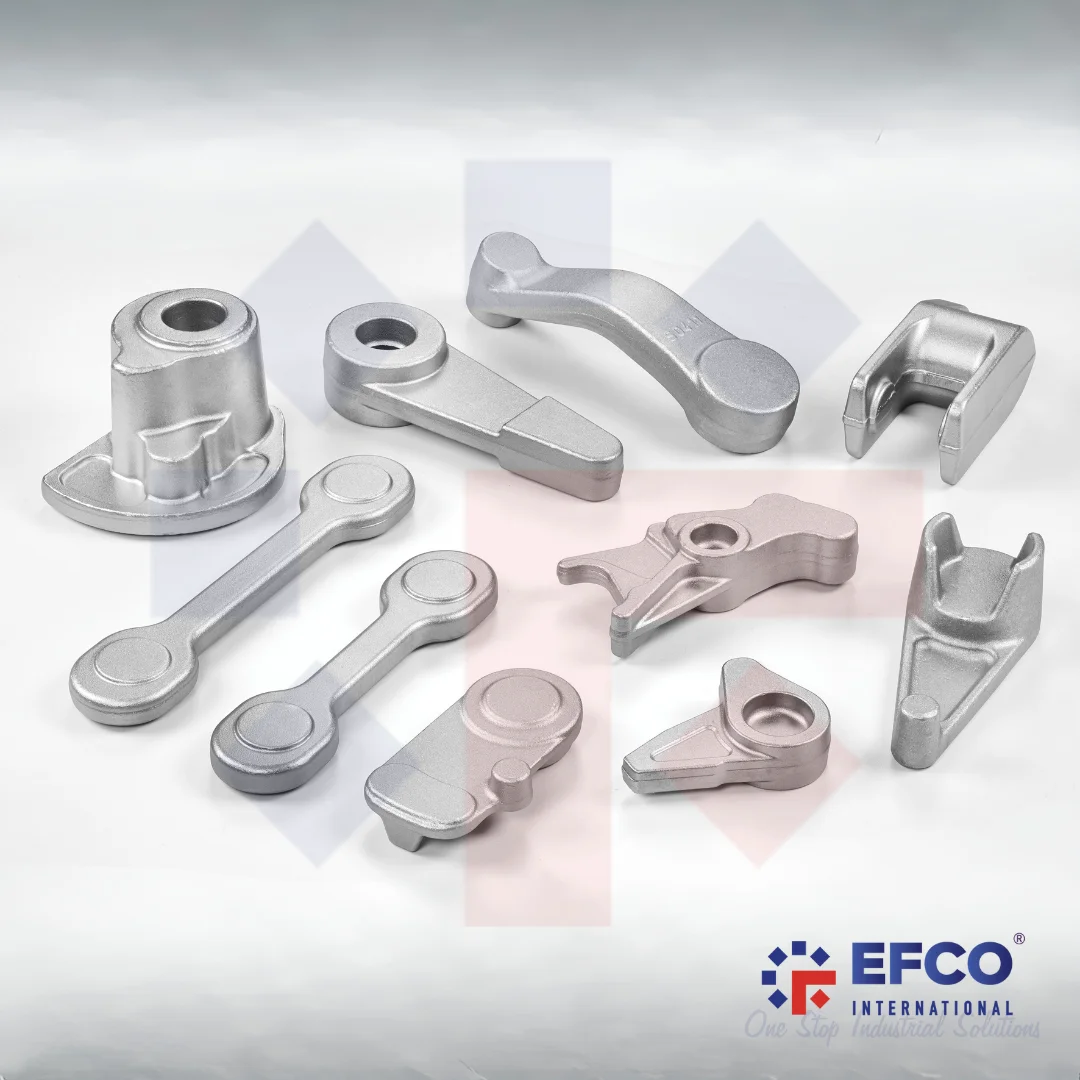

Forging

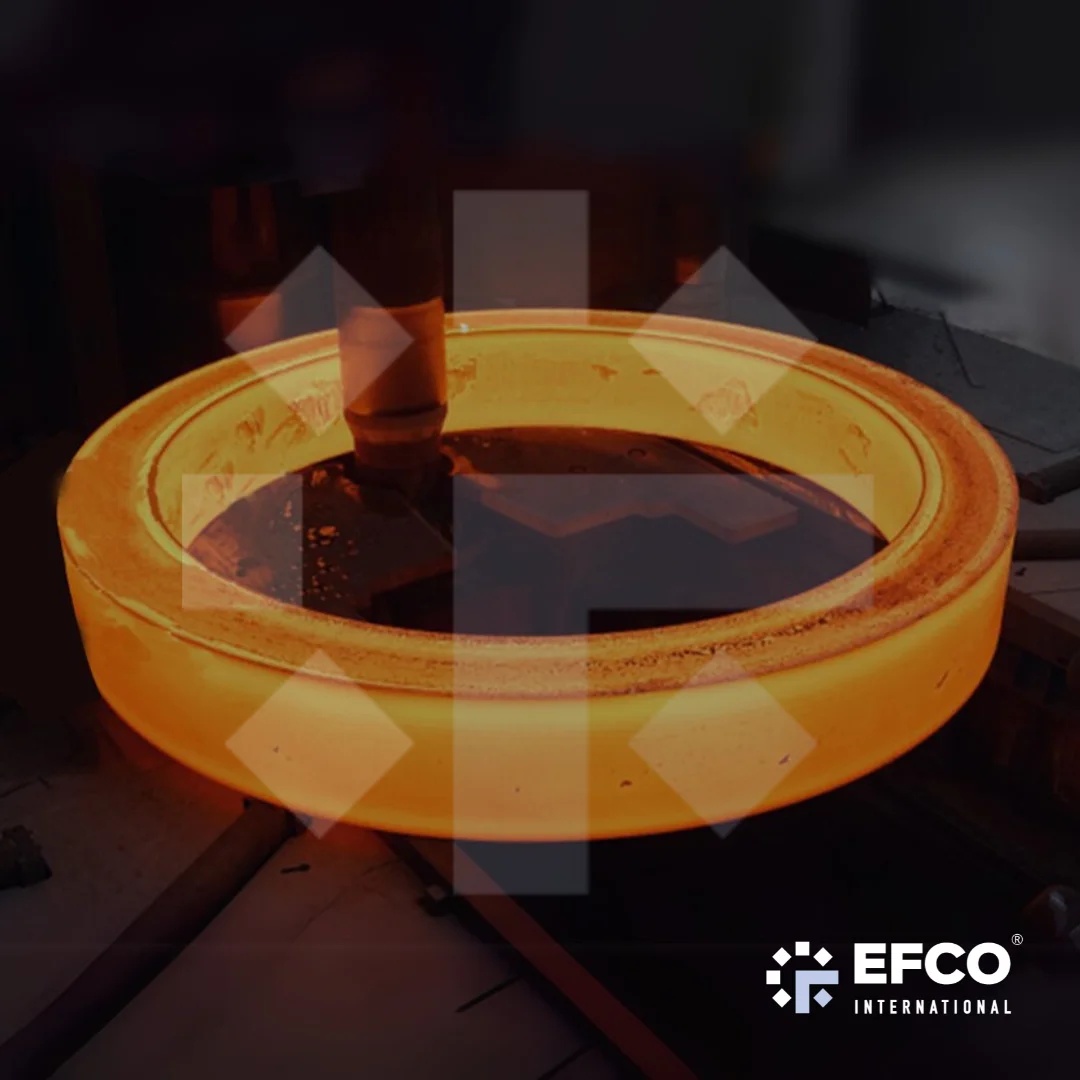

Hot forging is a robust manufacturing process in which metal is shaped at elevated temperatures. It is preferred for components that require high strength and toughness. EFCO provides hot-forging solutions to many industries, from automotive to energy.

Types of Hot Forging

-

Open-Die Forging

-

Closed-Die (Impression-Die) Forging

-

Free Forging

Scroll to the bottom for more details.

Open-Die Forging

A flexible forging method in which large cross-section parts are freely shaped.

Materials Used: Carbon steel, alloy steels, stainless steel, nickel and titanium alloys

Specifications and Tolerances:

-

Standards: ASTM A668, ASTM A788

-

Dimensional tolerance: ±1 – 3 mm

-

Surface roughness: Ra 6.3 – 12.5 µm

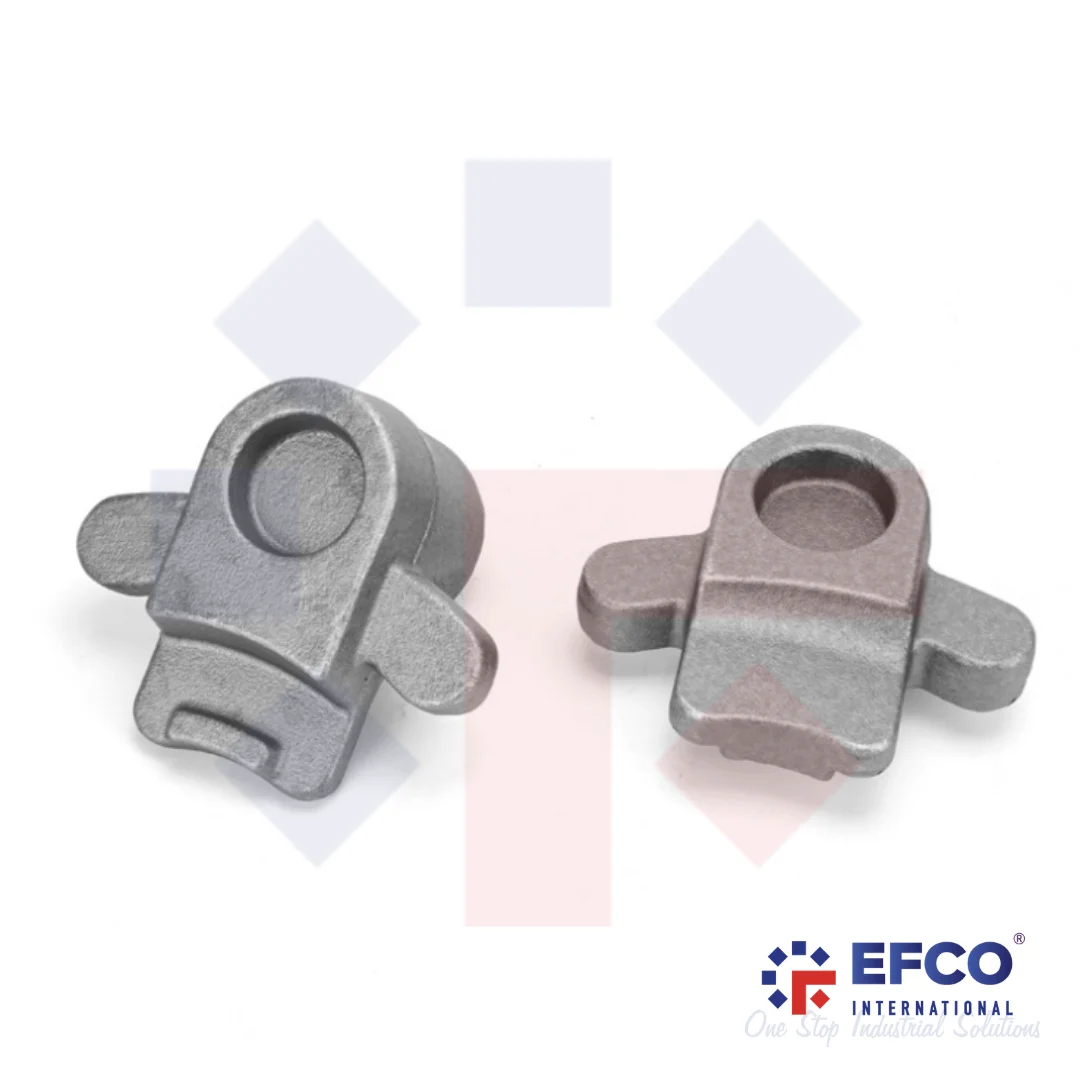

Closed-Die (Impression-Die) Forging

Near-net shaping is performed within special dies. Suitable for mass production.

Materials Used: Carbon/alloy steels, aluminum alloys, stainless steels

Specifications and Tolerances:

-

Standards: EN 10243

-

Dimensional tolerance: ±0.3 – 1.0 mm

-

Surface roughness: Ra 3.2 – 6.3 µm

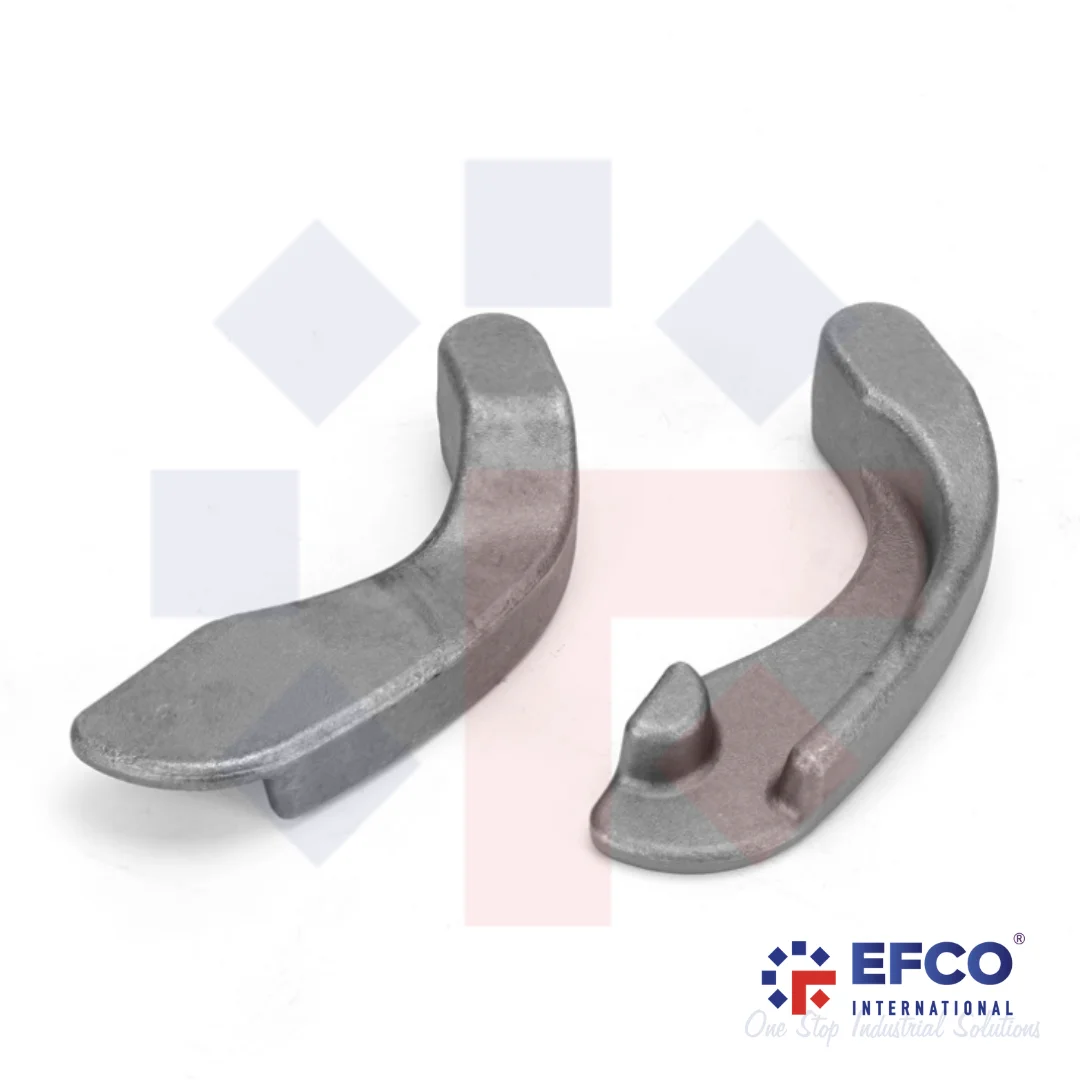

Free Forging

A forging method performed without dies or with simple tools, offering flexible production.

Materials Used: Carbon/alloy steels, stainless steels, nickel and titanium alloys

Specifications and Tolerances:

-

Standards: EN 10250

-

Dimensional tolerance: ±2 – 5 mm

-

Surface roughness: Ra 6.3 – 12.5 µm

EFCO’s Contribution

-

Determines the most suitable production method and material for the project.

-

Provides certified solutions in compliance with international standards.

-

Ensures quality assurance with dimensional measurement reports and NDT tests.

-

Offers turnkey solutions with advantages in delivery time and cost.

We are always ready to help you and answer your questions!