Cold Forging and Fastening Equipment

Cold forging is a precision manufacturing method in which metal is formed at or near room temperature. It offers high surface quality and tight tolerance advantages for fasteners. EFCO provides fastener solutions to a wide range of industries.

Types of Cold Forging

-

Bolt and Nut Production

-

Rivet and Pin Production

-

Special Fasteners

Scroll to the bottom for more details.

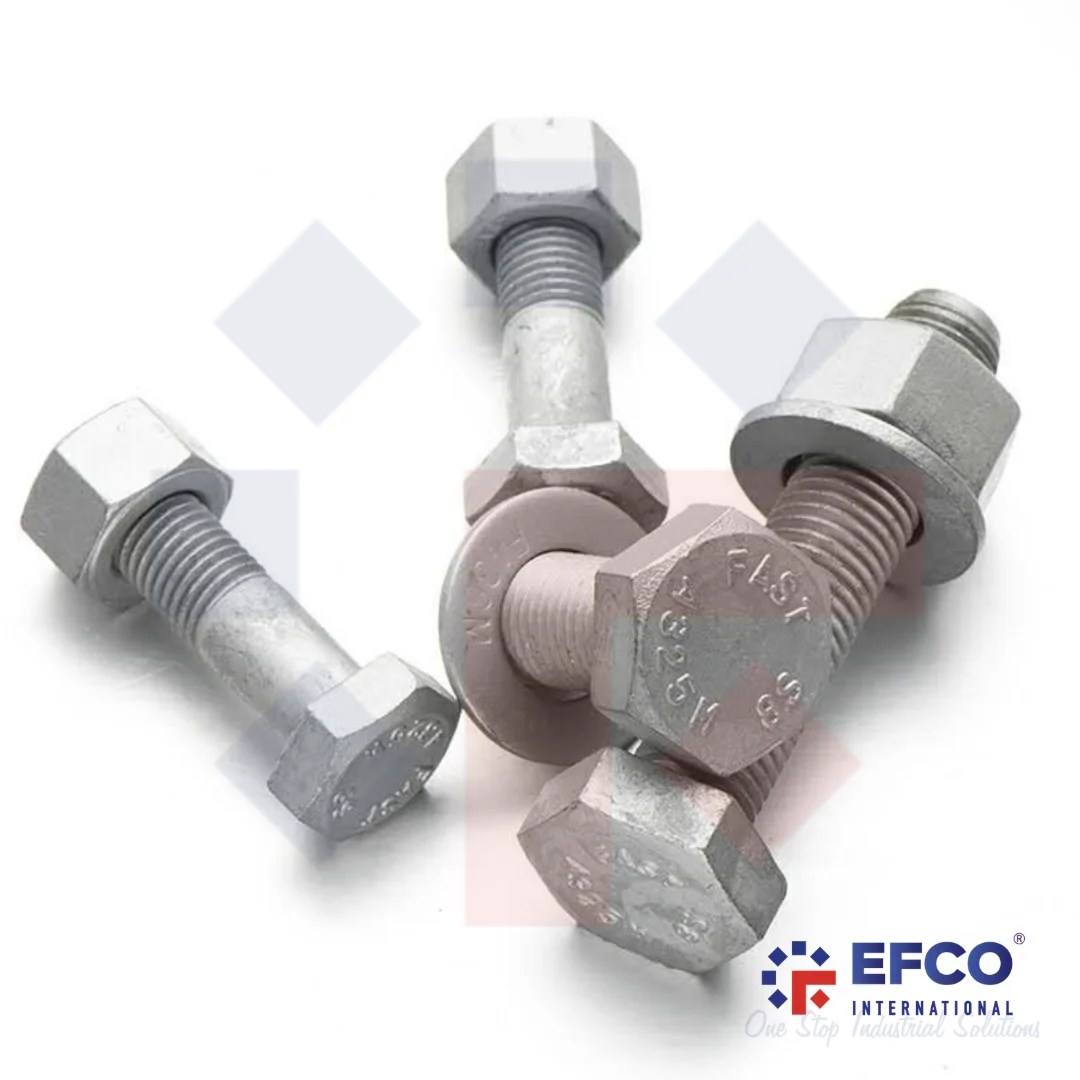

Bolt and Nut Production

Manufactured on multi-stage cold forging presses at high speed and with tight tolerances.

Materials Used: Carbon and alloy steels, stainless steels, aluminum

Specifications and Tolerances:

-

Standards: ISO 898, ISO 965

-

Dimensional tolerance: ±0.05 – 0.15 mm

-

Surface roughness: Ra 0.8 – 3.2 µm

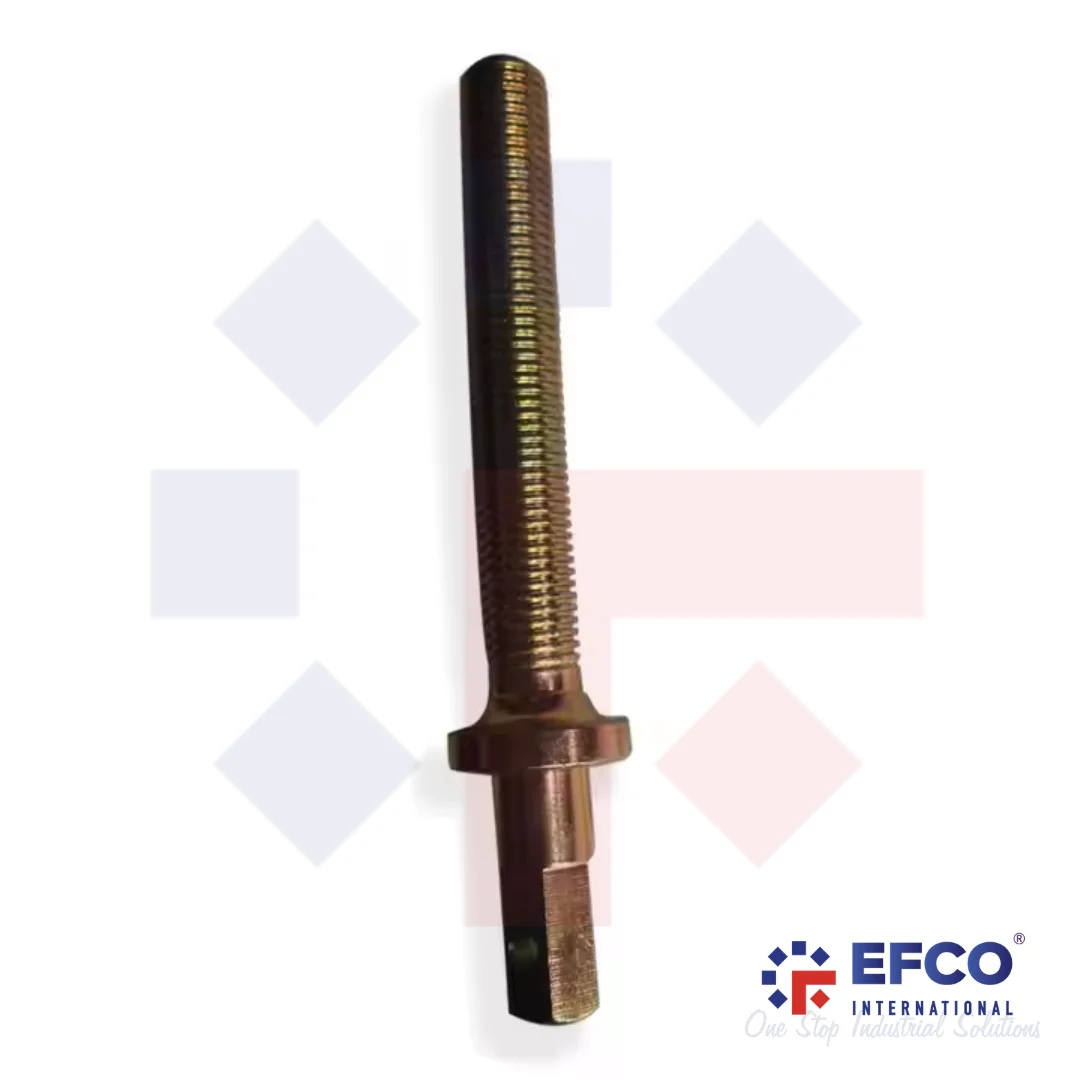

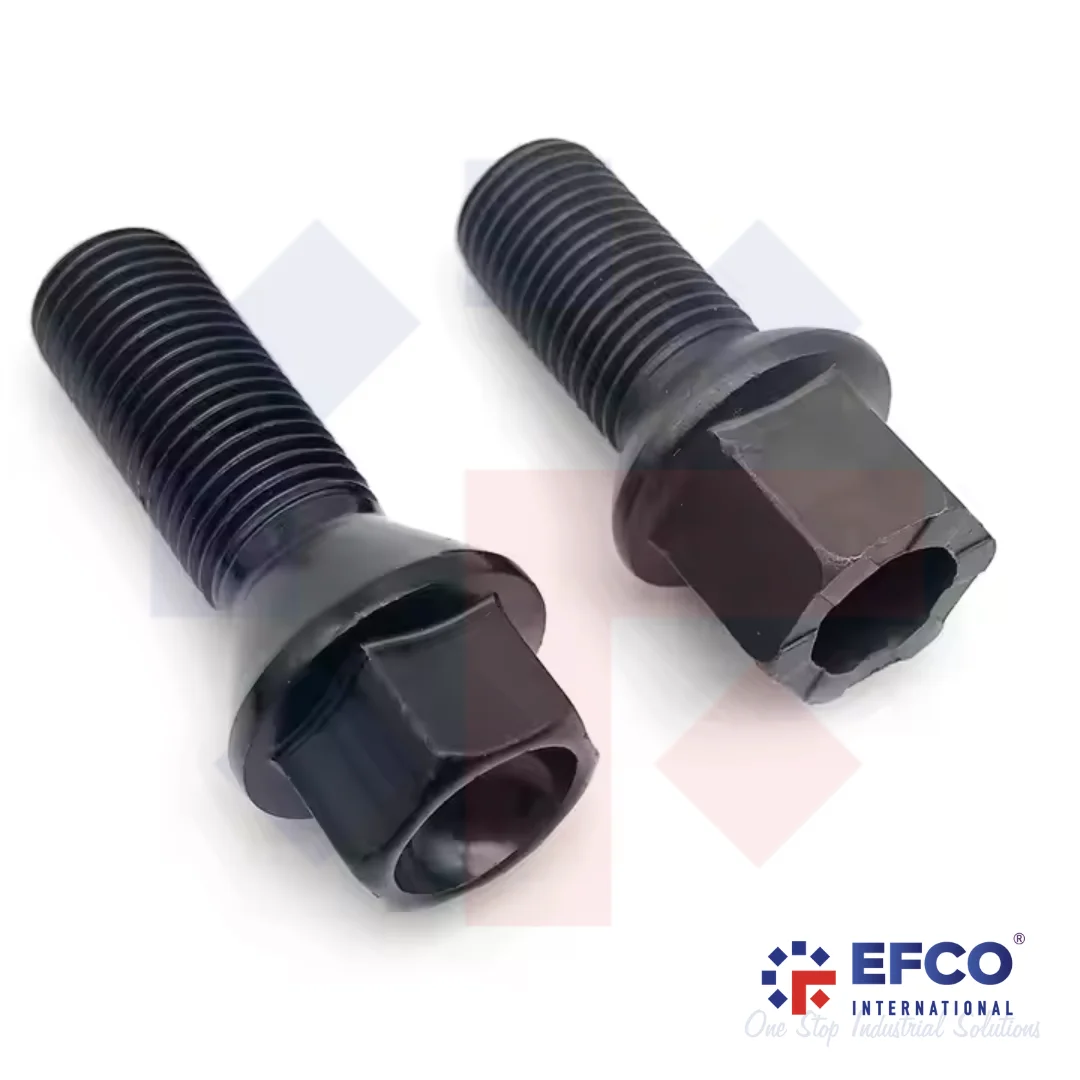

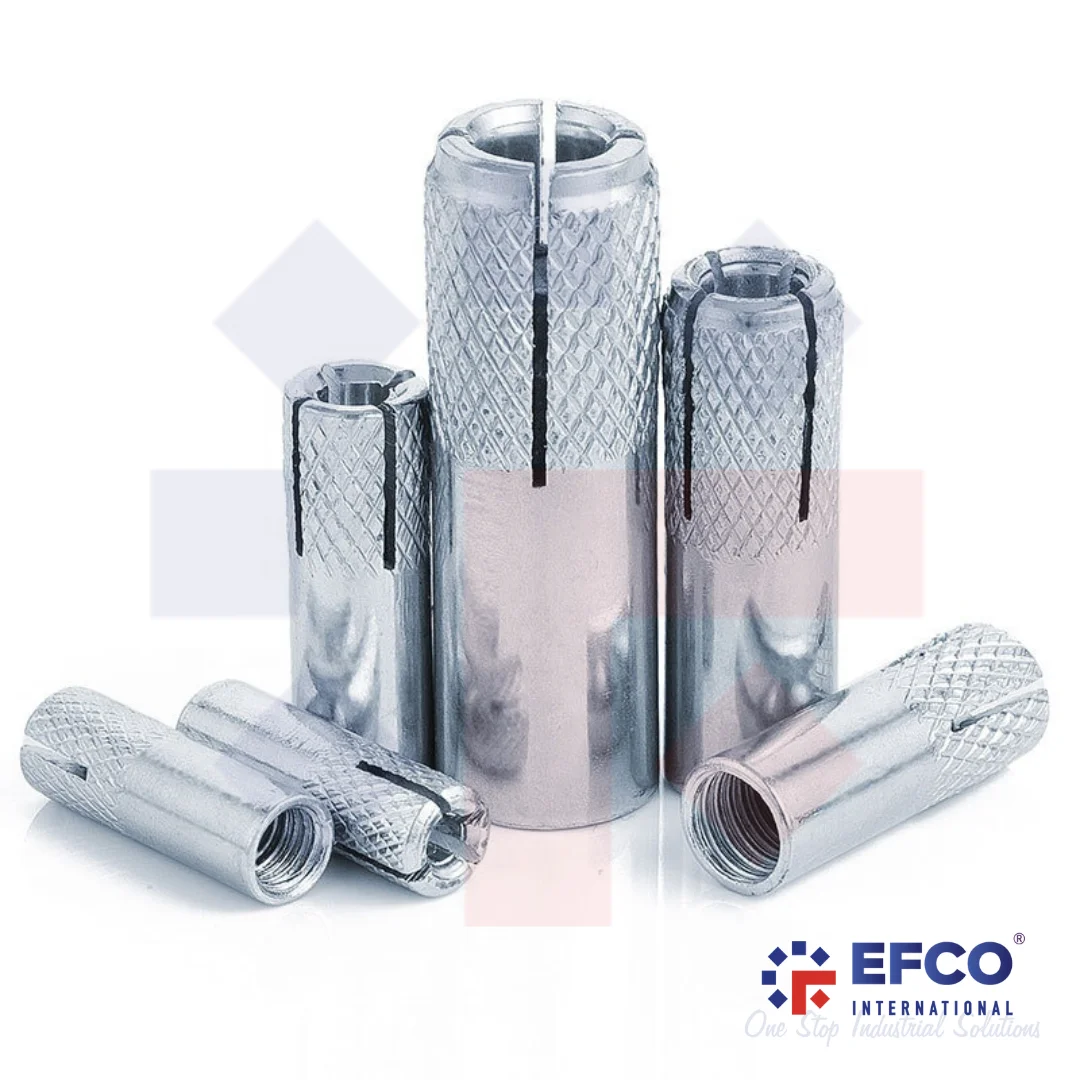

Special Fasteners

Produced according to customer-specific geometry and coating requirements.

Cold forging provides faster and more economical production compared to machining.

Materials Used: Alloy steels, stainless steels, aluminum, brass

Specifications and Tolerances:

-

Standards: ISO 965, ISO 4042

-

Dimensional tolerance: ±0.05 – 0.20 mm

-

Surface roughness: Ra 0.8 – 3.2 µm

EFCO’s Contribution

-

Determines the most suitable production method and material for the project.

-

Provides certified solutions in compliance with international standards.

-

Ensures quality assurance with dimensional measurement reports and NDT tests.

-

Offers turnkey solutions with advantages in delivery time and cost.

We are always ready to help you and answer your questions!