Casting

Casting is one of the most fundamental production methods, enabling metals to be melted and poured into moulds to shape them. This method can be used to produce both large, heavy components and intricate parts with tight tolerances. EFCO offers reliable casting solutions for various industries.

Types of Casting:

Sand Casting

Precision Casting

Pressure Casting

Scroll down for more detailed information.

Sand Casting – Investment Casting – Die Casting

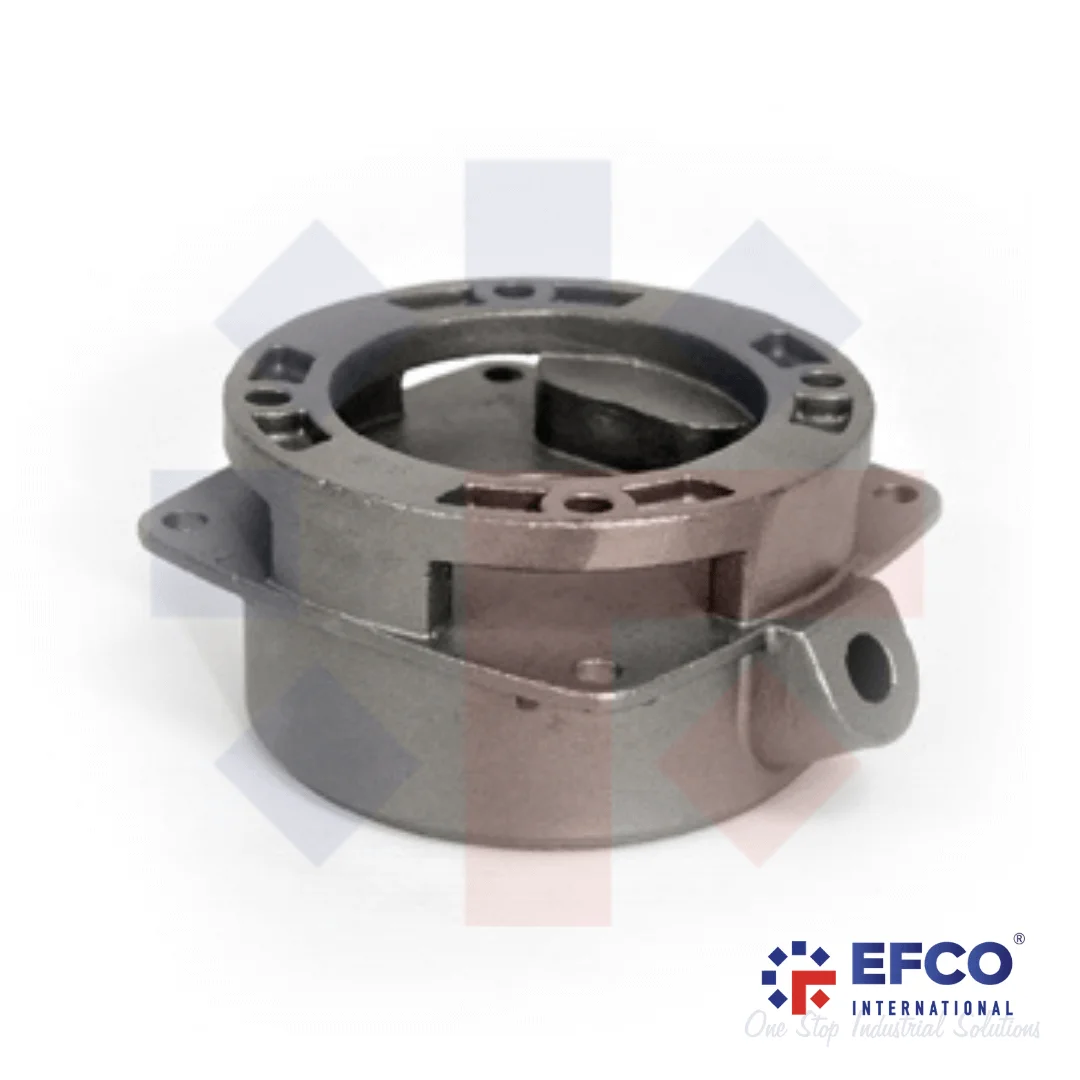

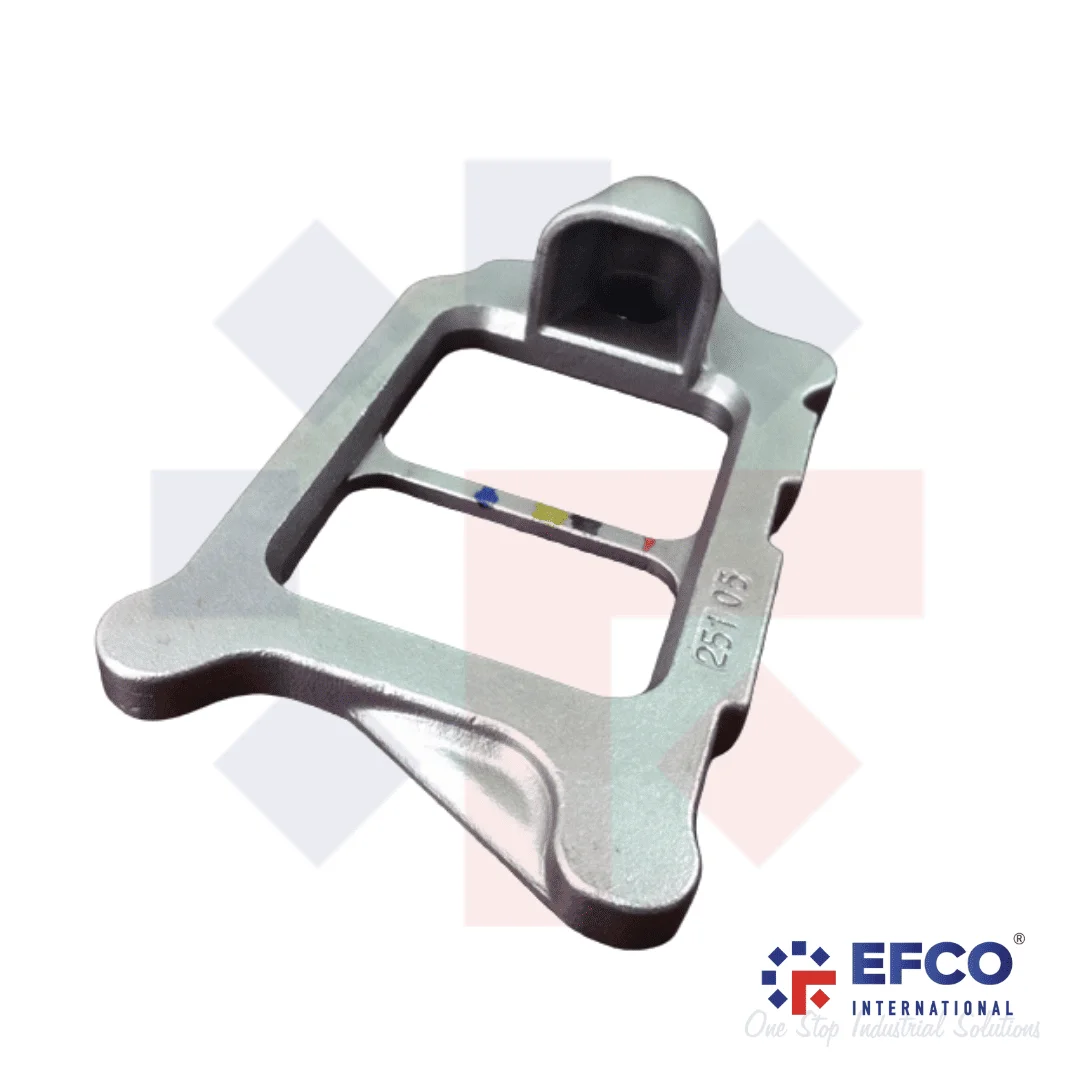

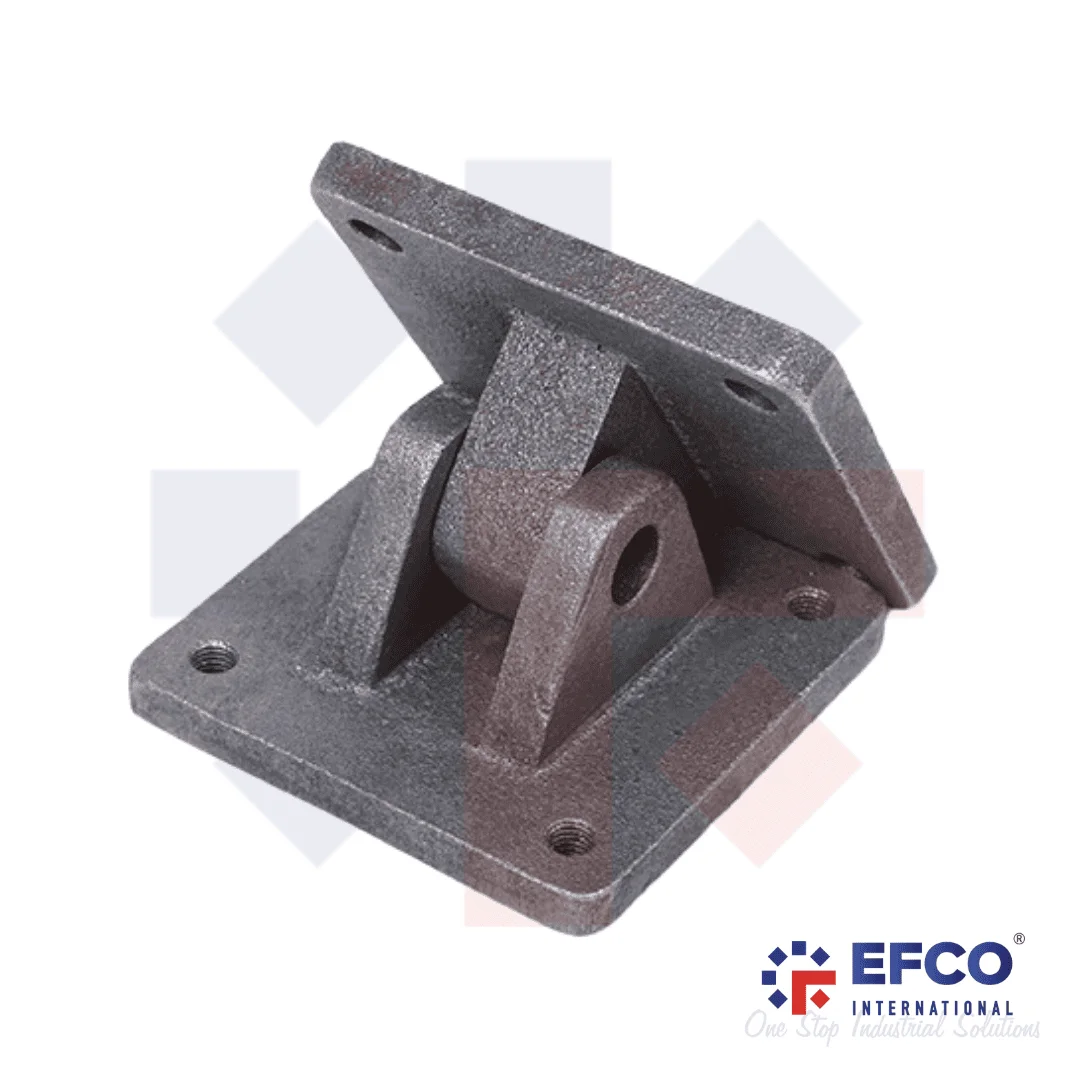

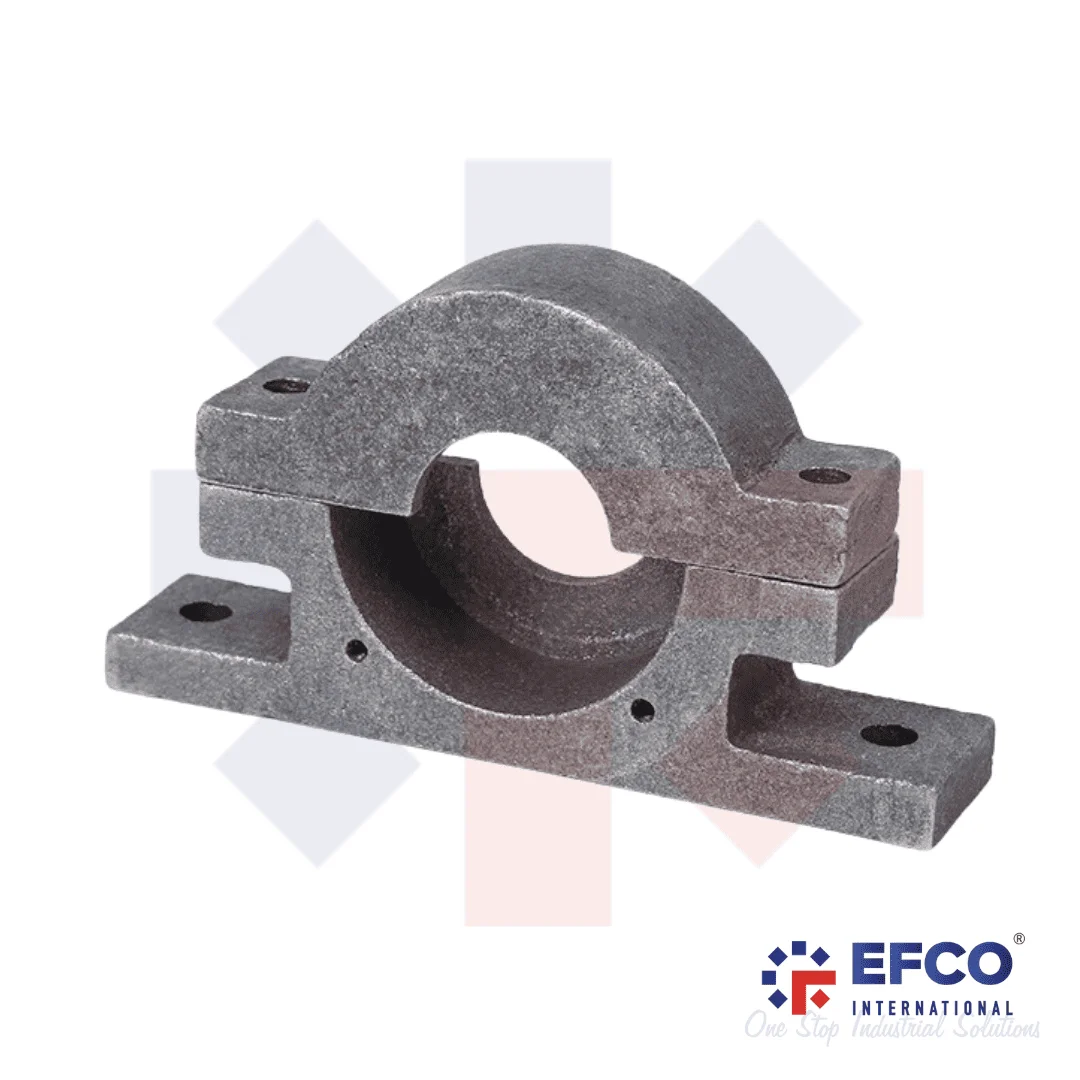

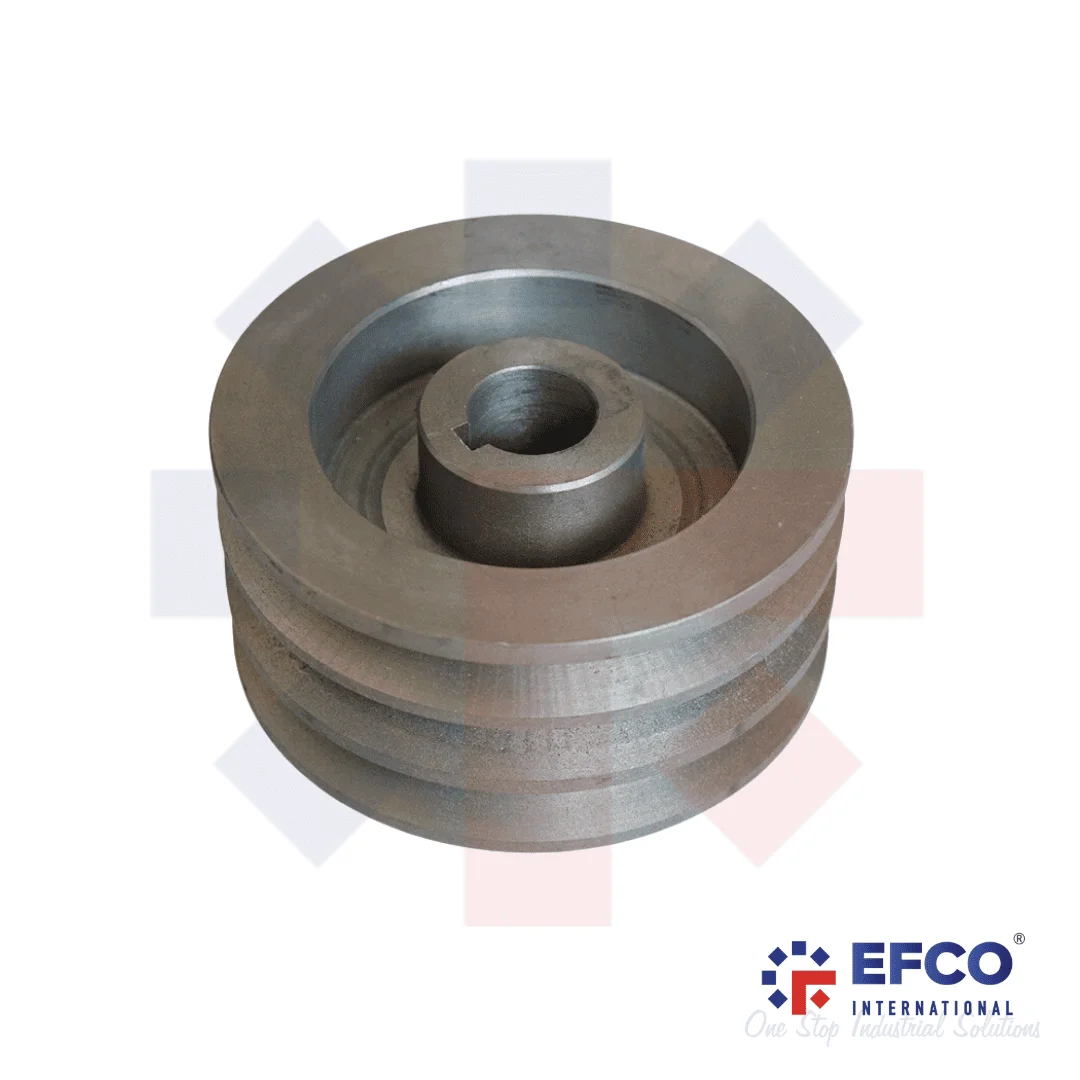

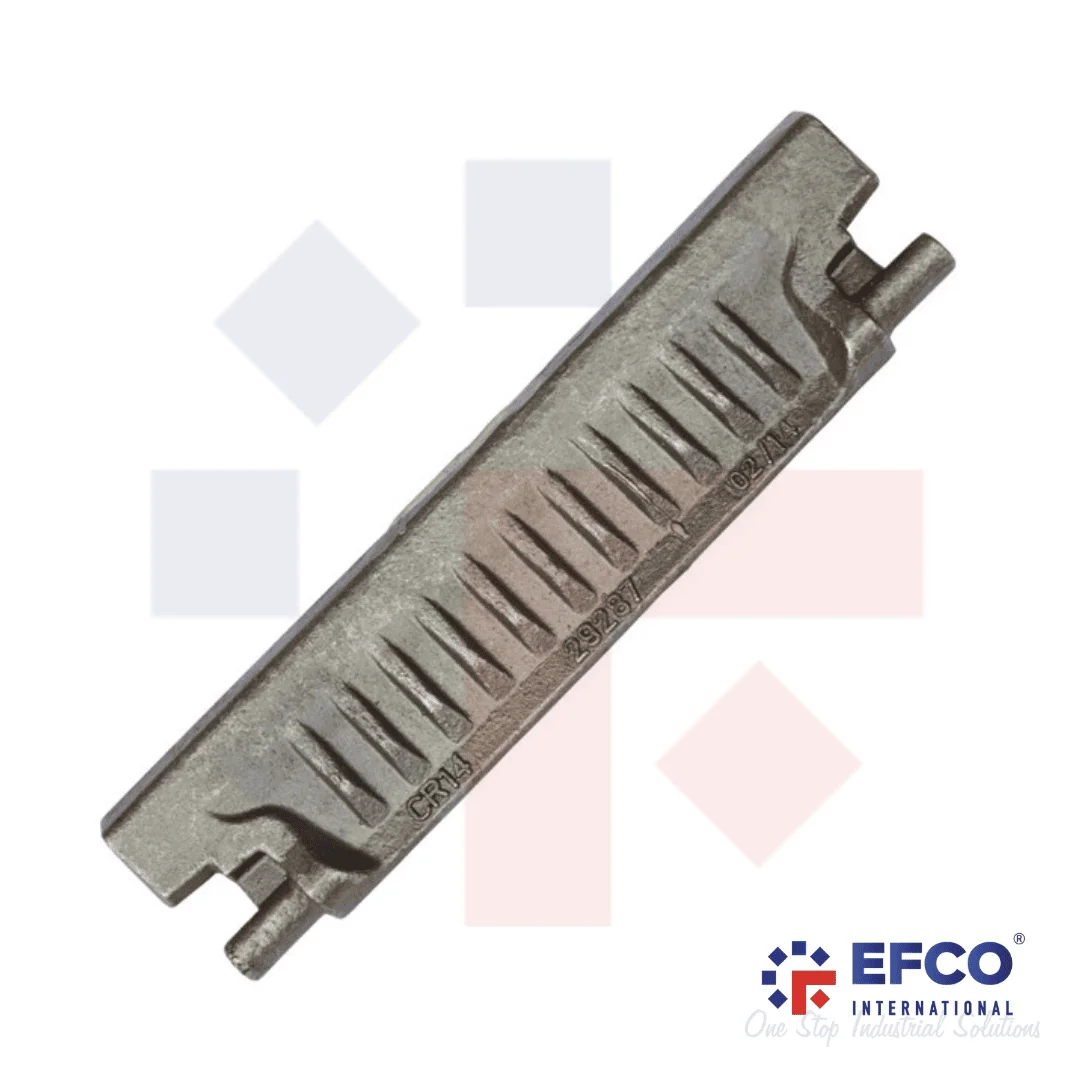

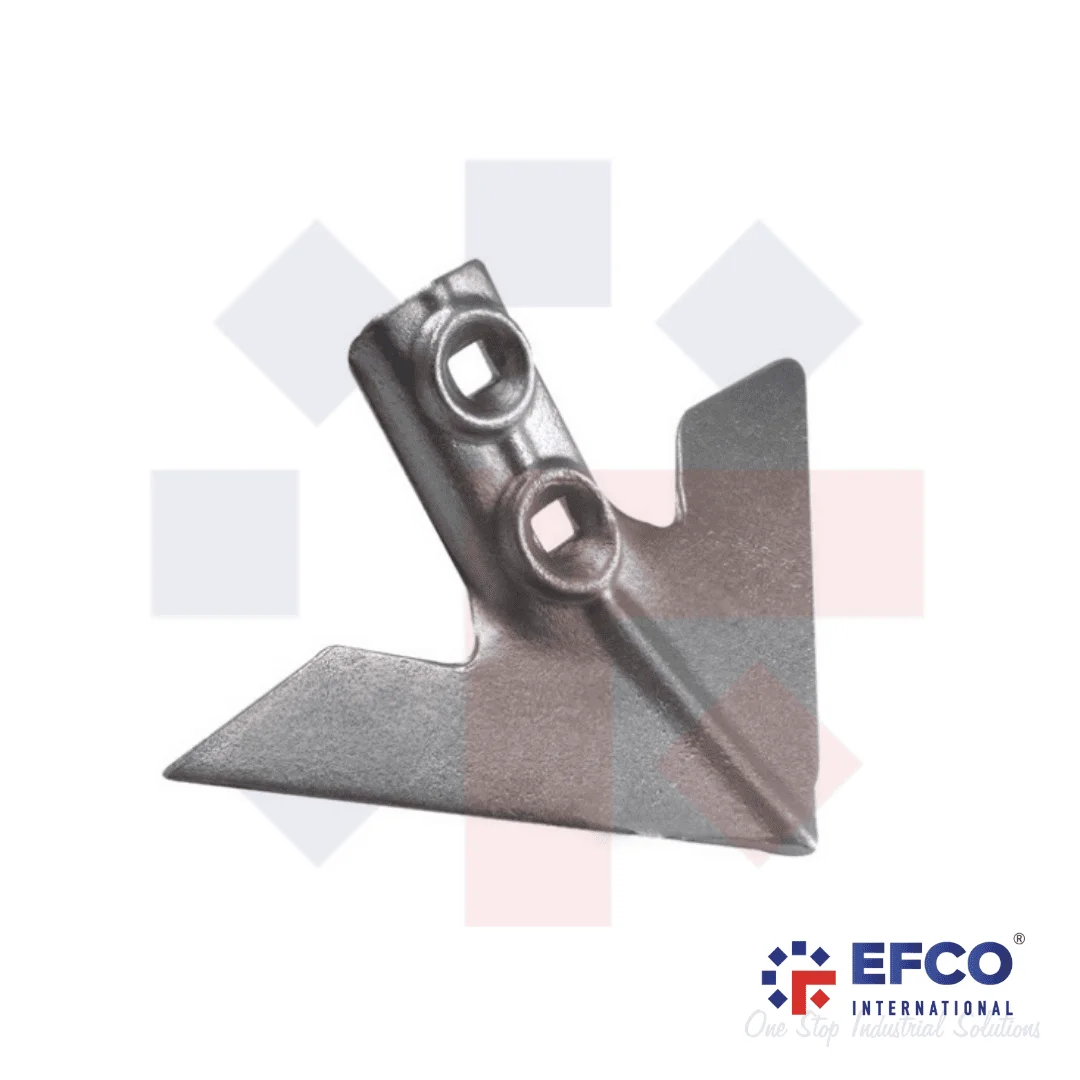

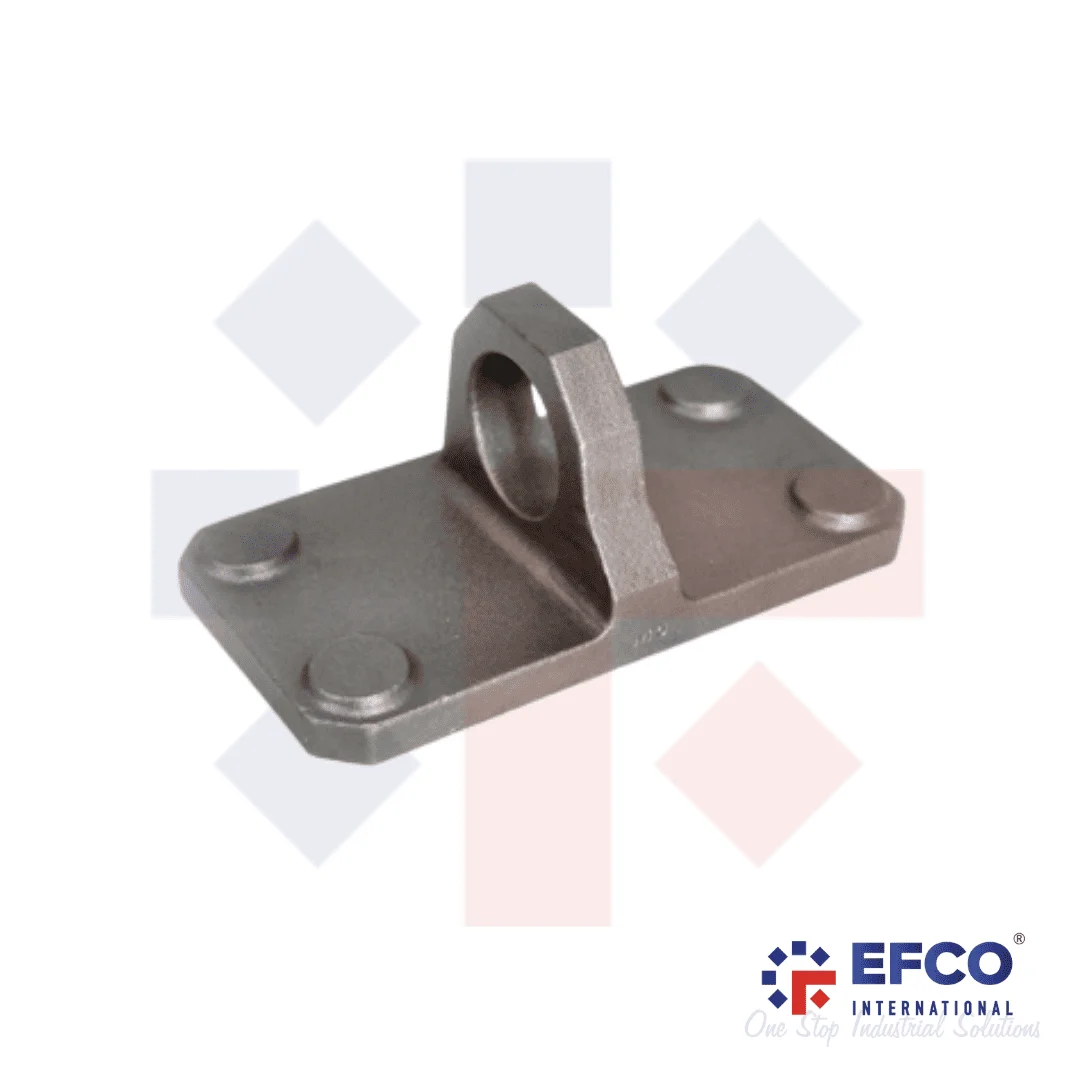

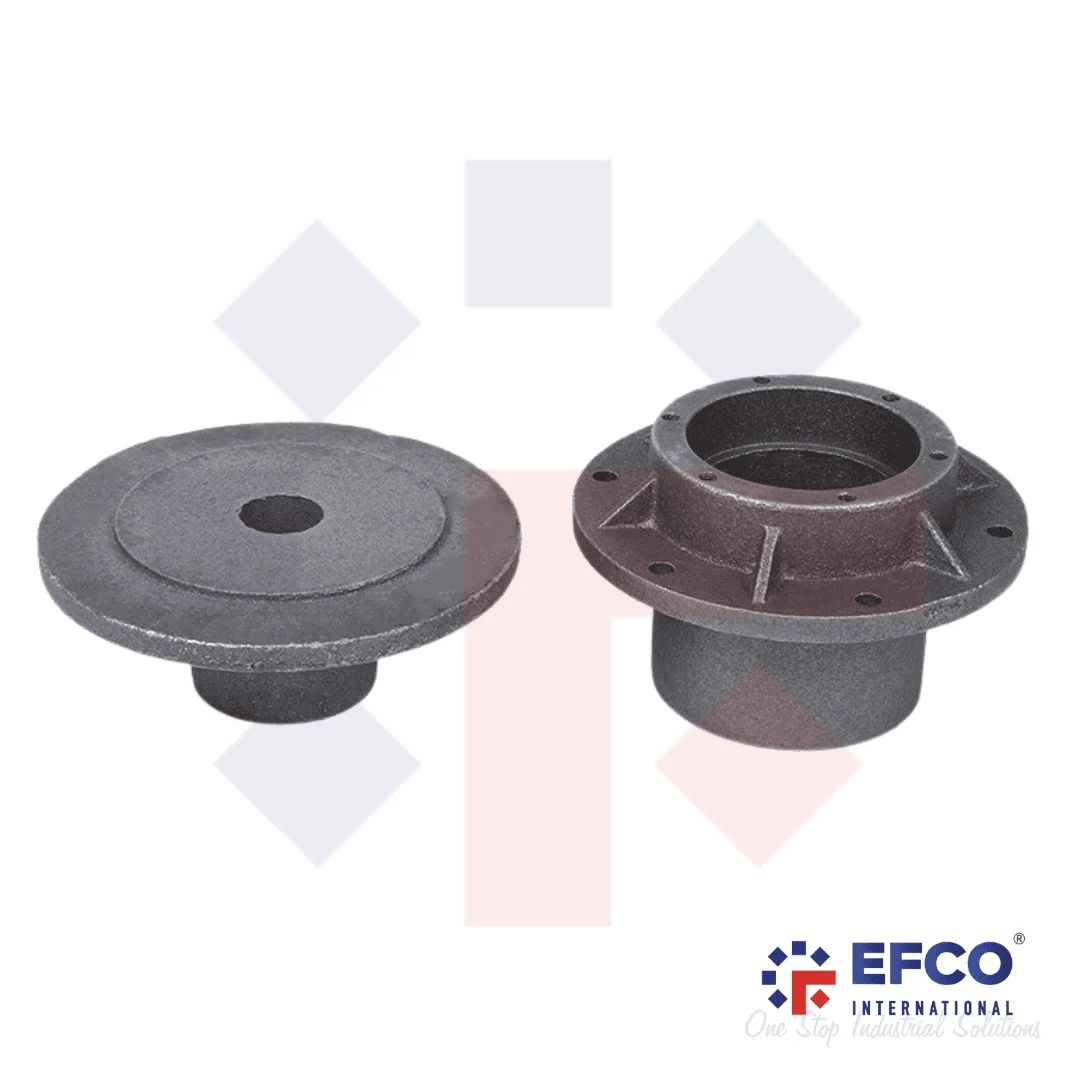

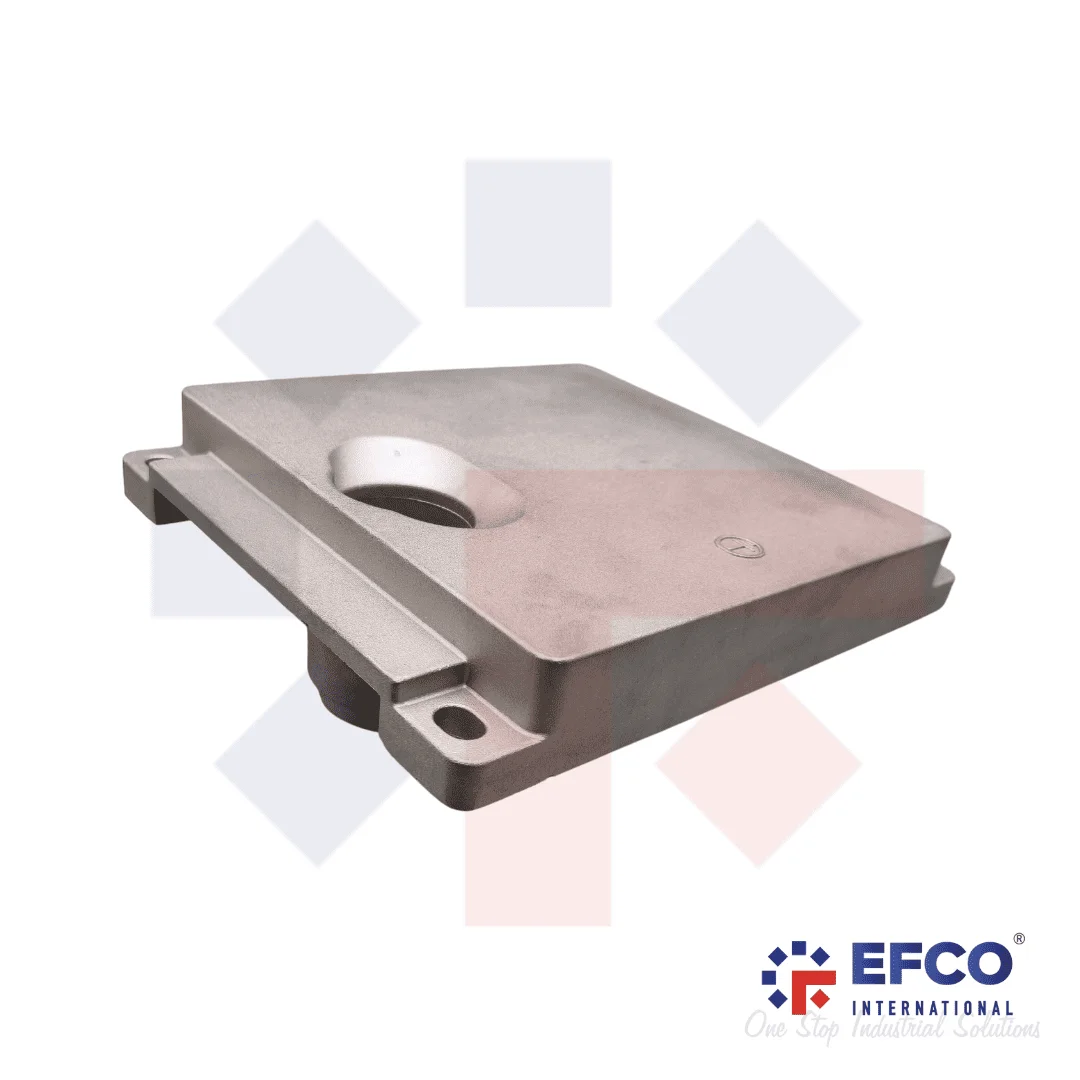

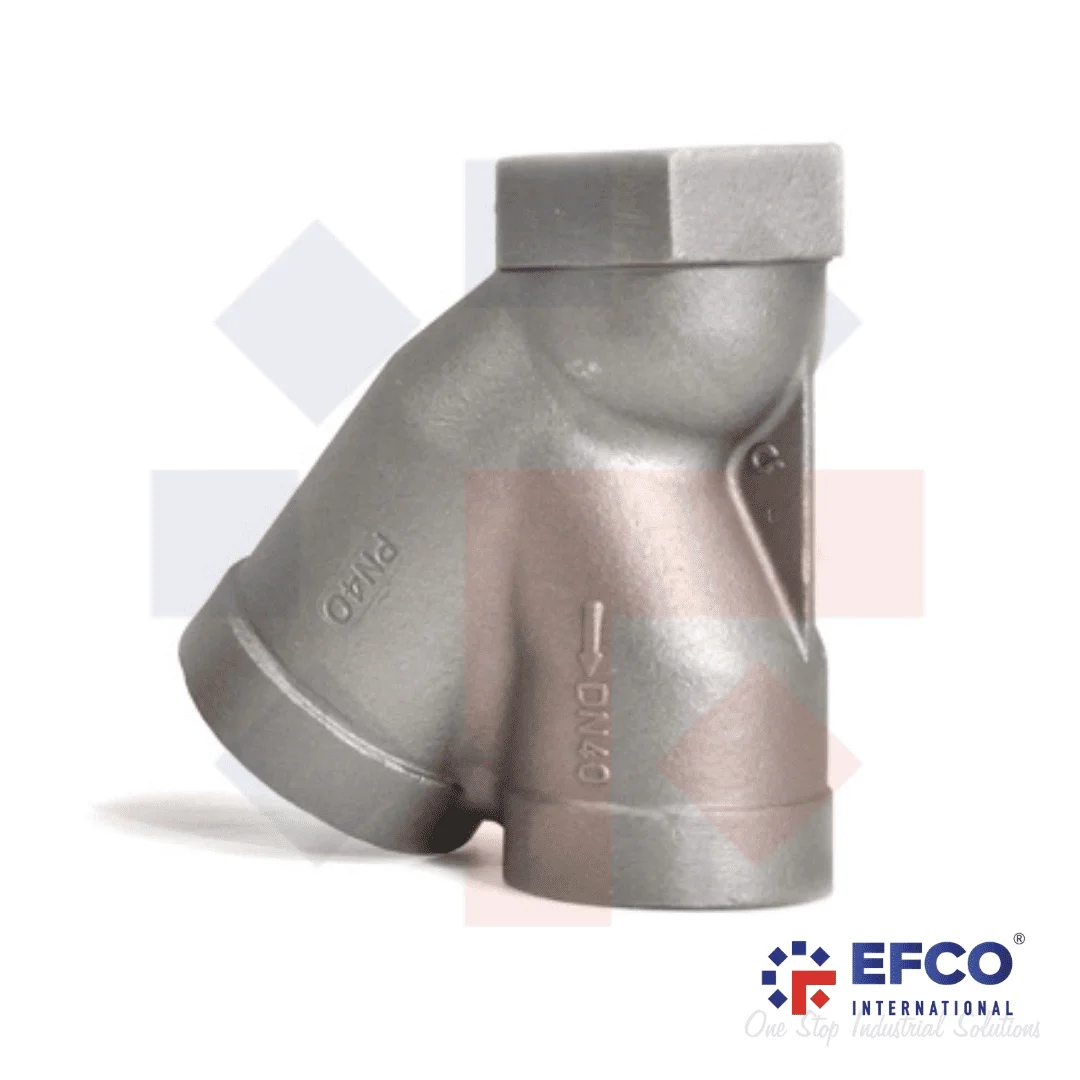

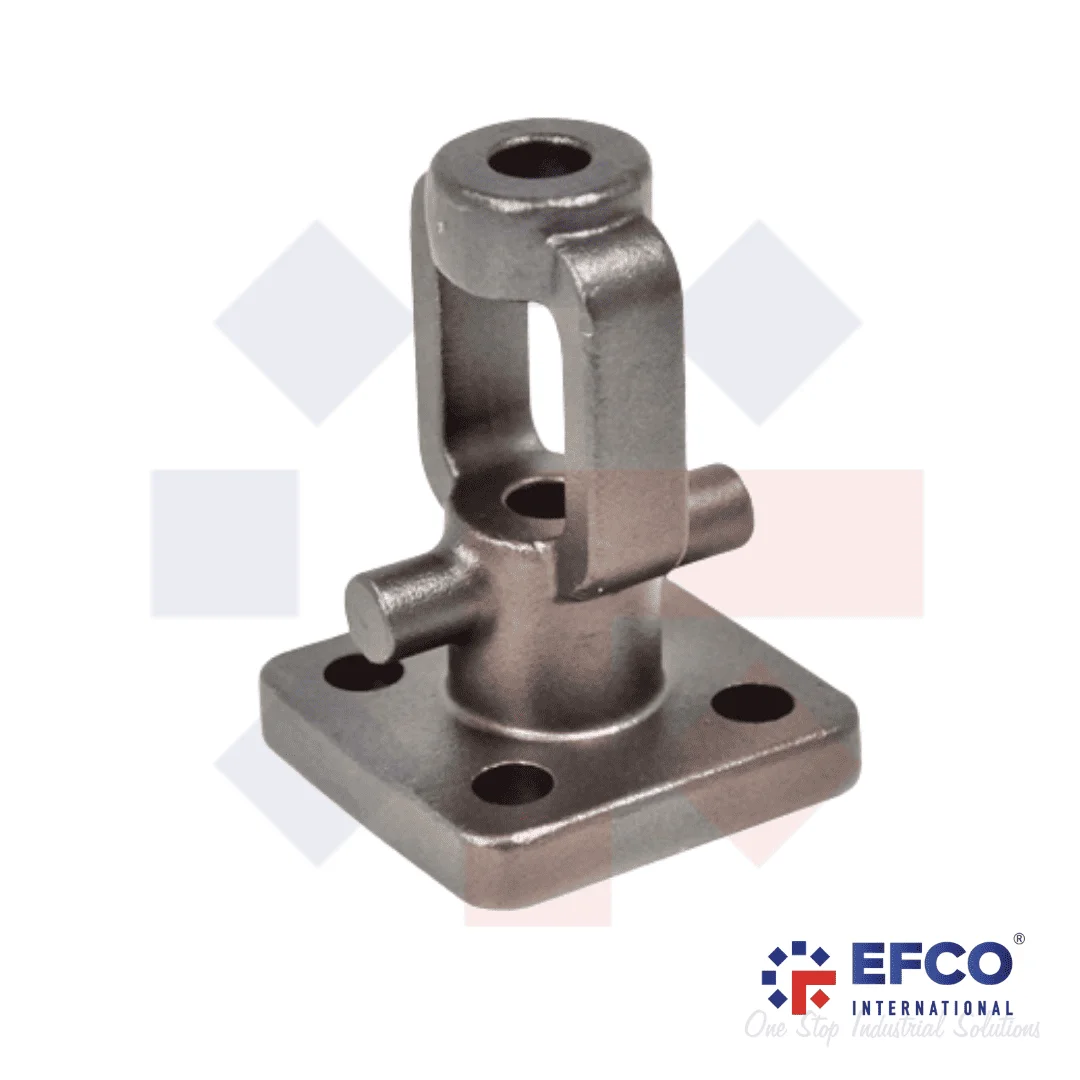

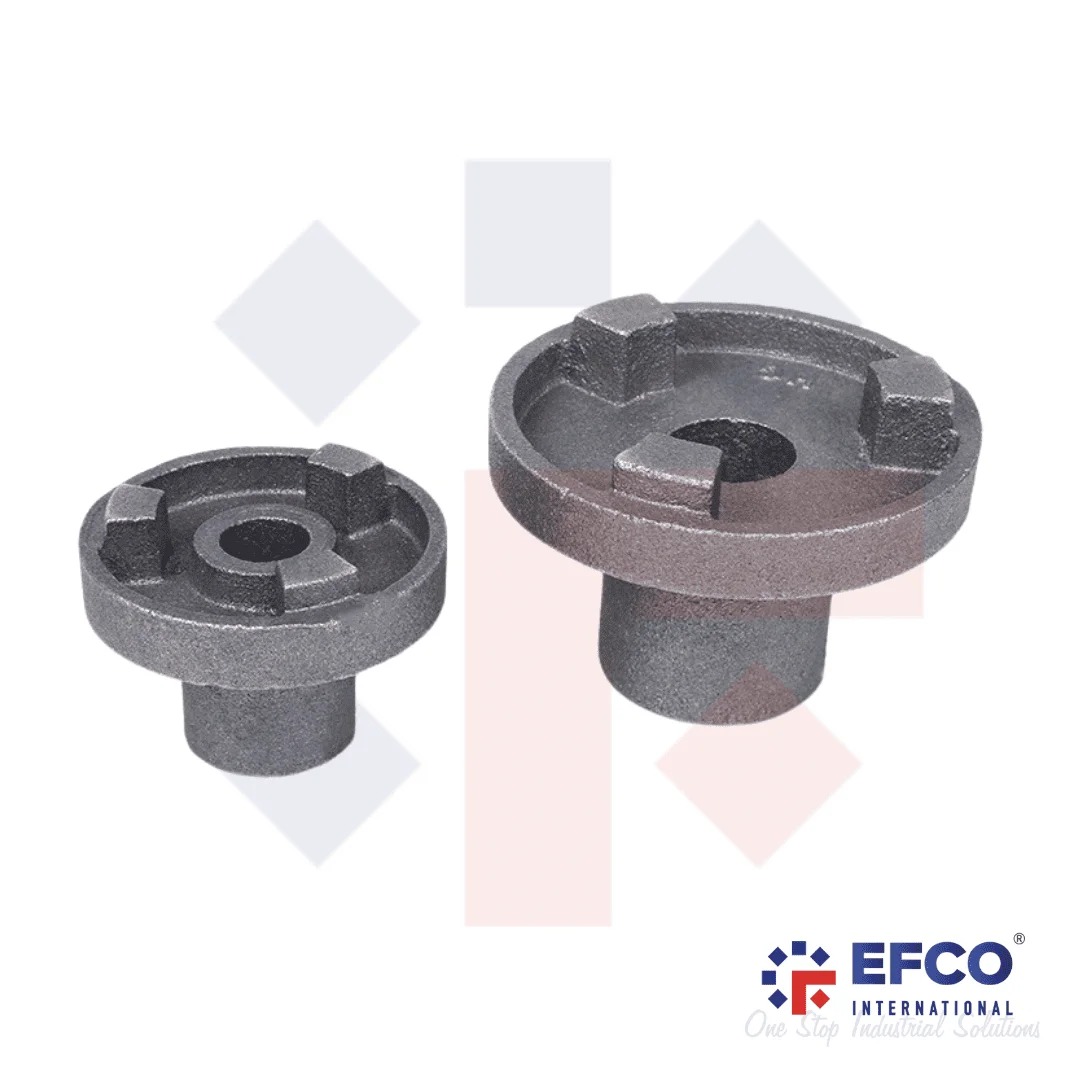

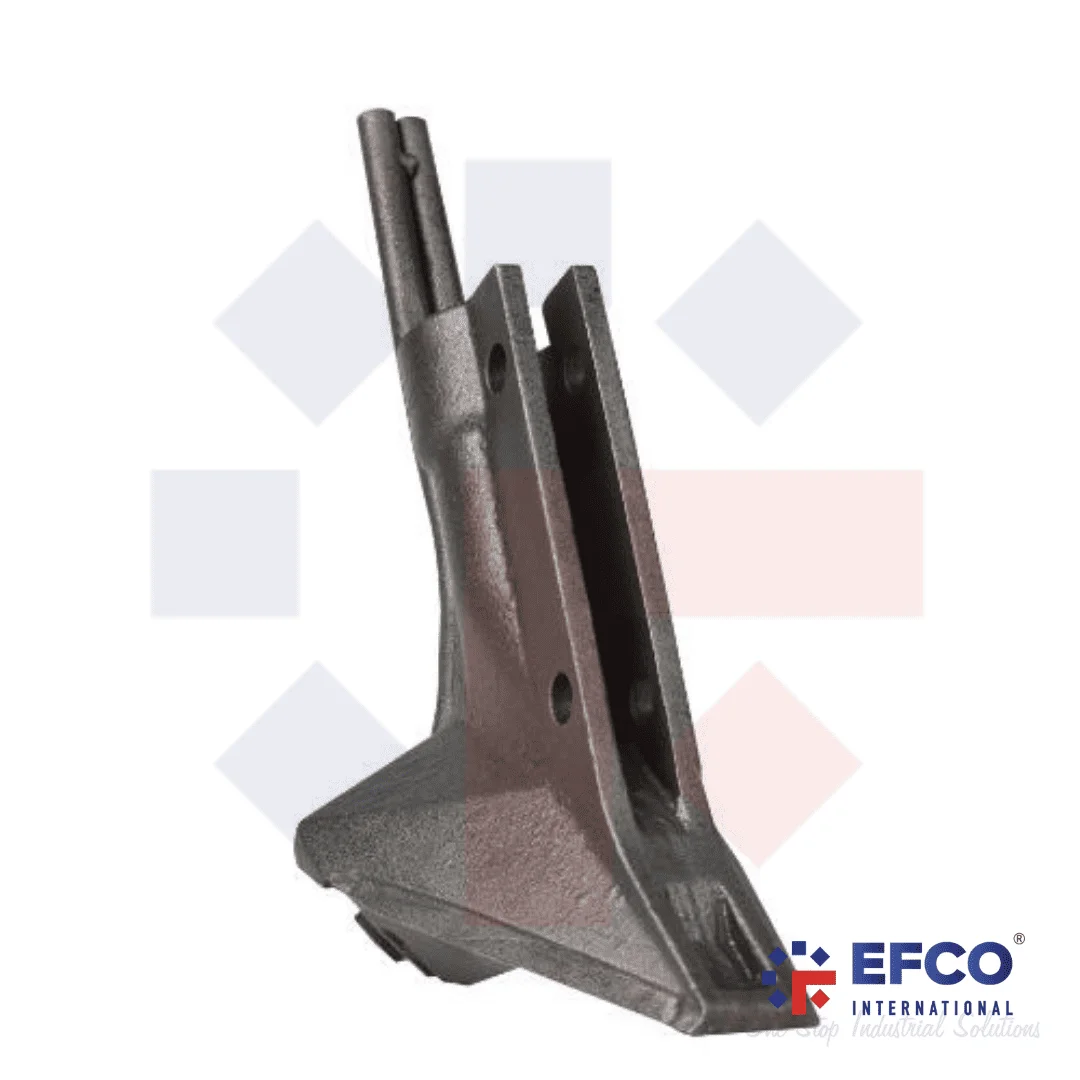

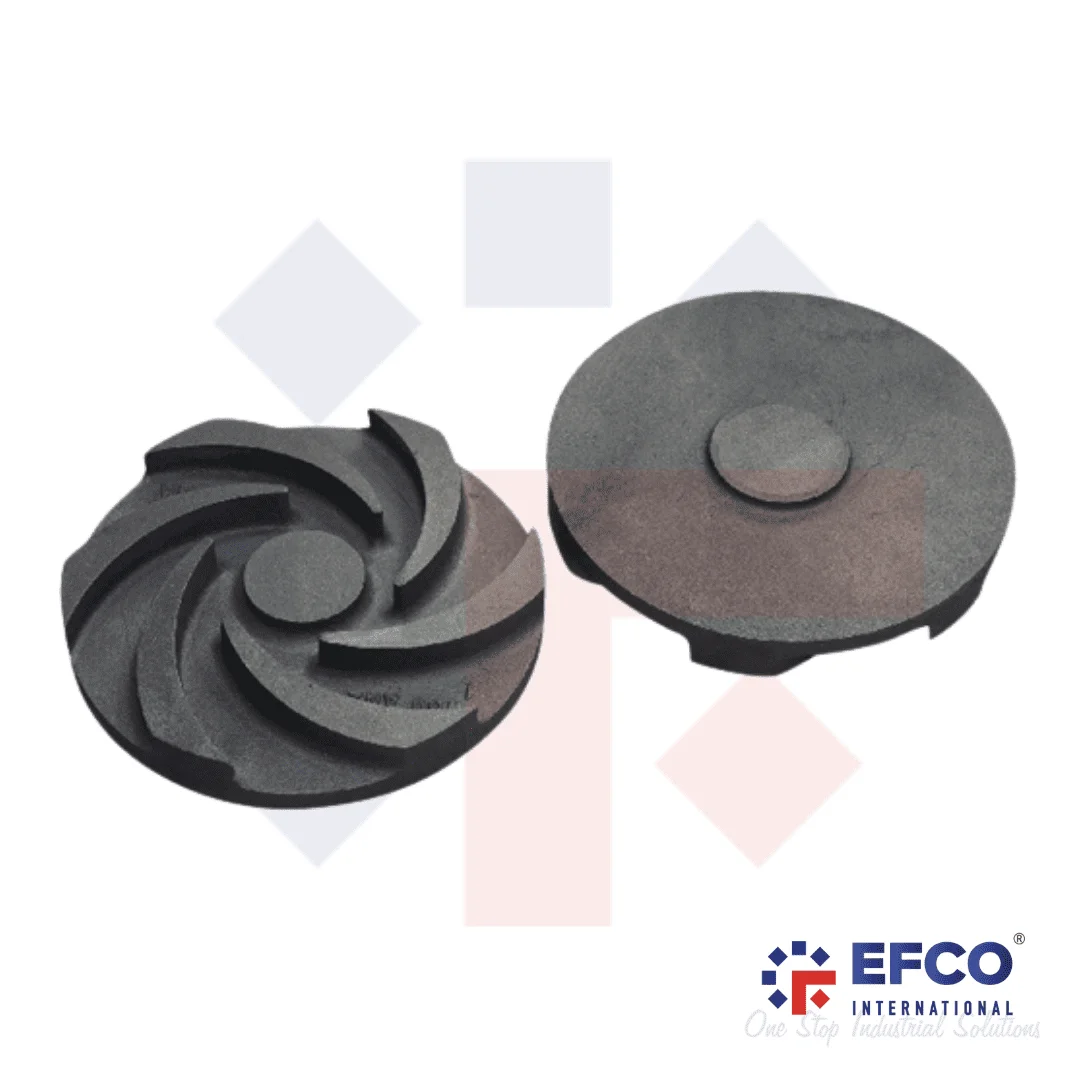

Sand Casting

One of the oldest and most widely used casting methods. Molten metal is poured into a sand mold to take shape. It is low-cost and suitable for the production of large and heavy parts.

Materials Used: Gray cast iron, ductile iron, steel alloys, aluminum, bronze, brass

Specifications and Tolerances

-

Standards: DIN EN 1561 (gray iron), DIN EN 1563 (ductile iron)

-

Dimensional tolerance: ISO 8062 CT10 – CT13 (±1.5 – 3 mm)

-

Surface roughness: Ra 12.5 – 25 µm

Applications

-

Engine blocks and cylinder heads

-

Large pump and compressor housings

-

Turbine casings

-

Machine tool bodies

-

Construction infrastructure: manhole covers, flanges, fasteners

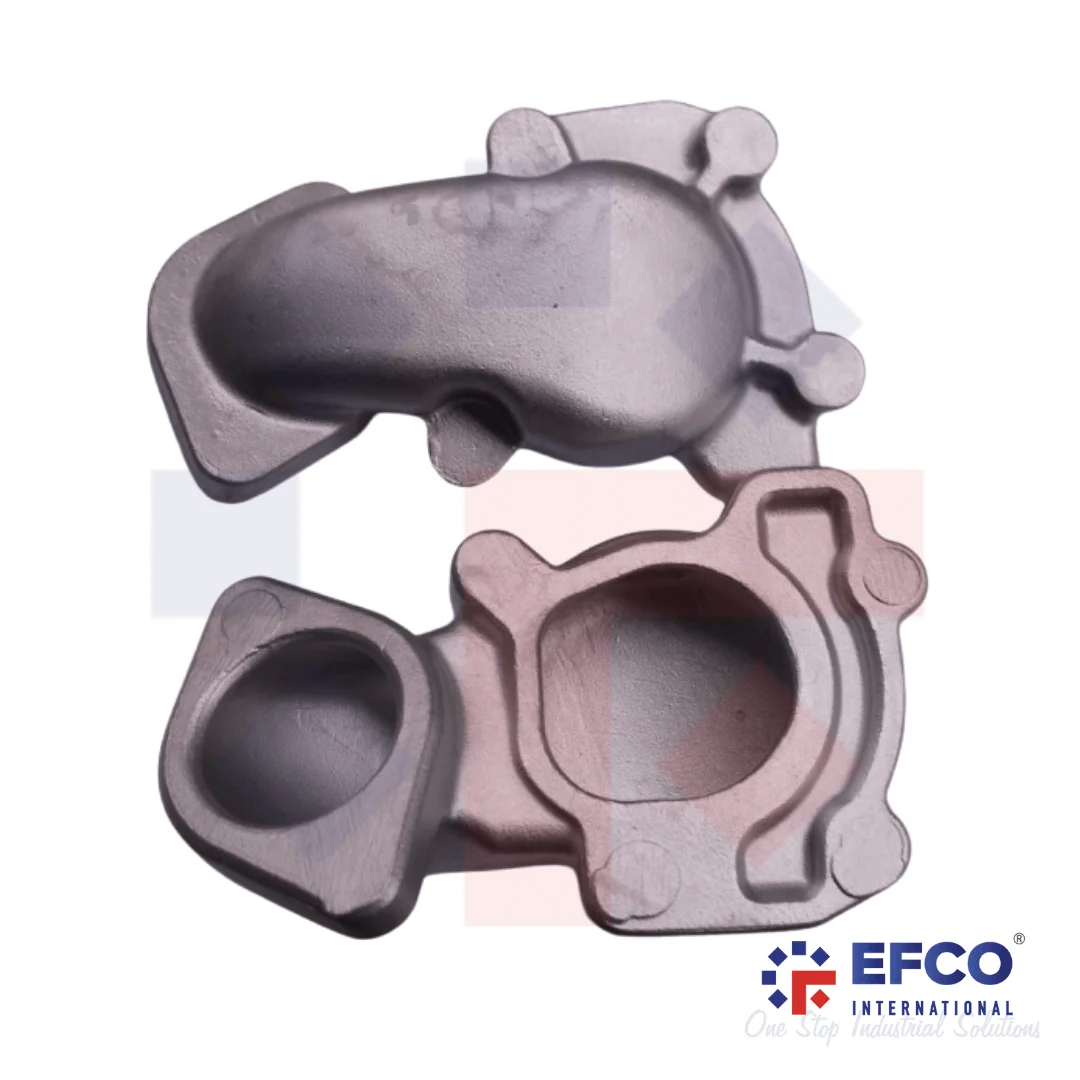

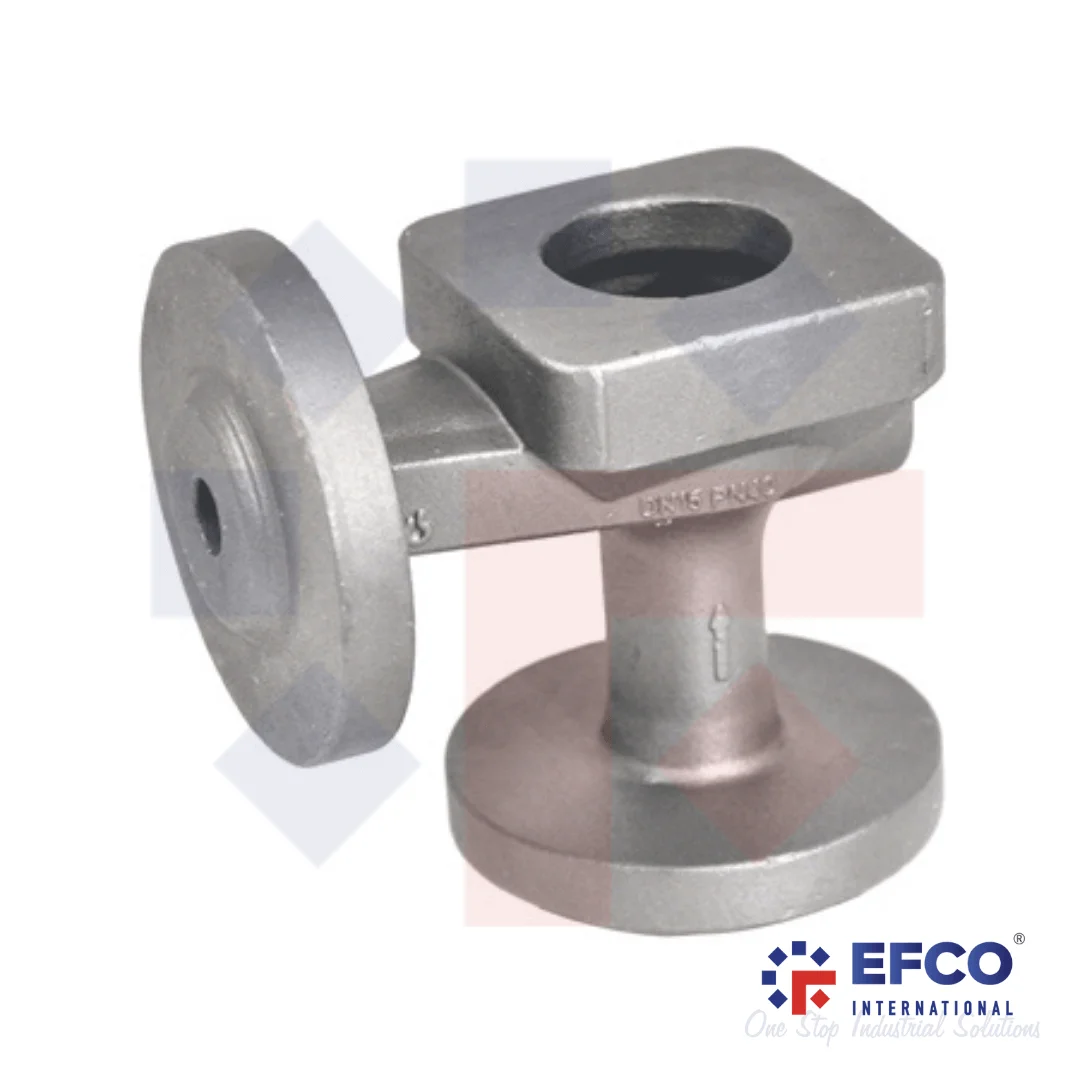

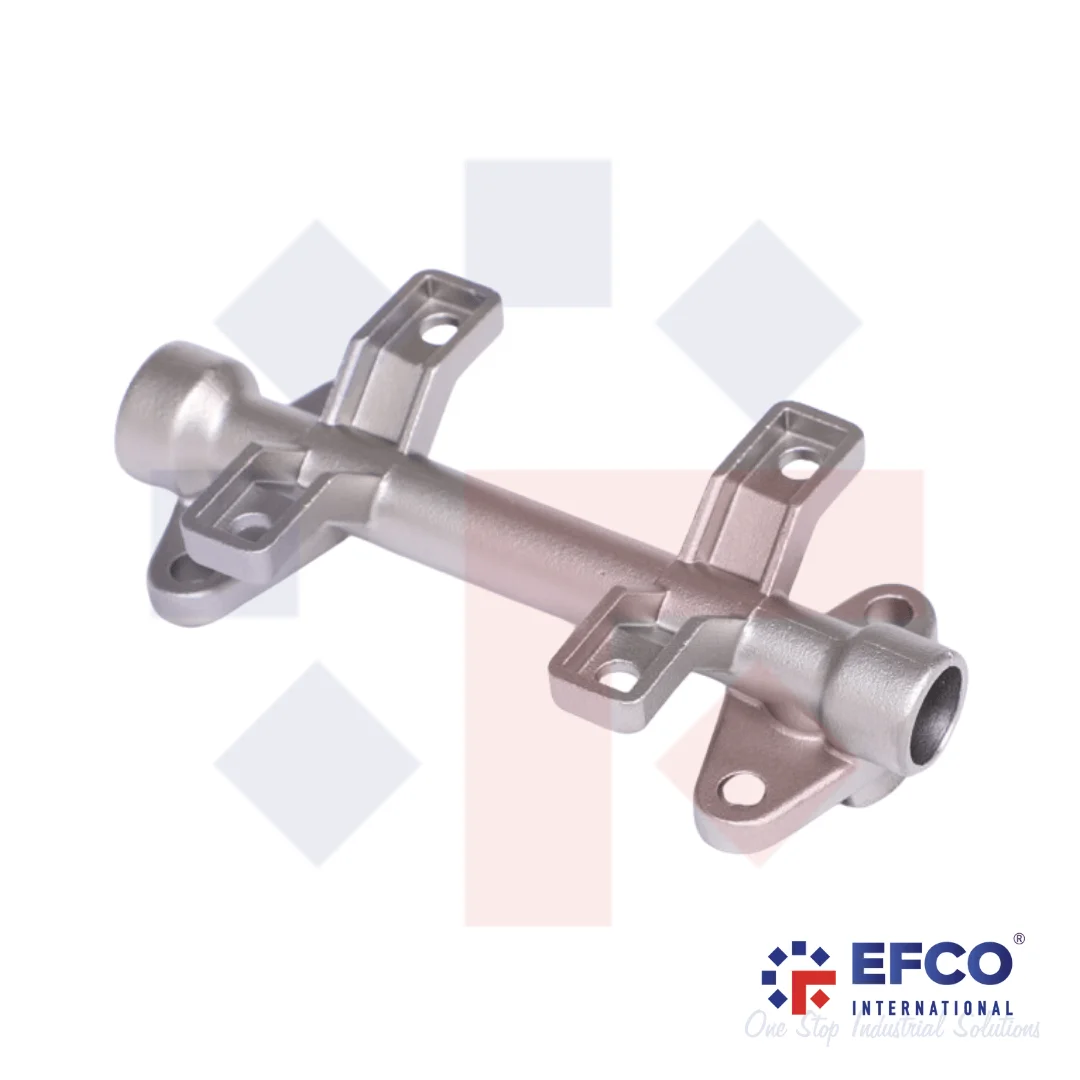

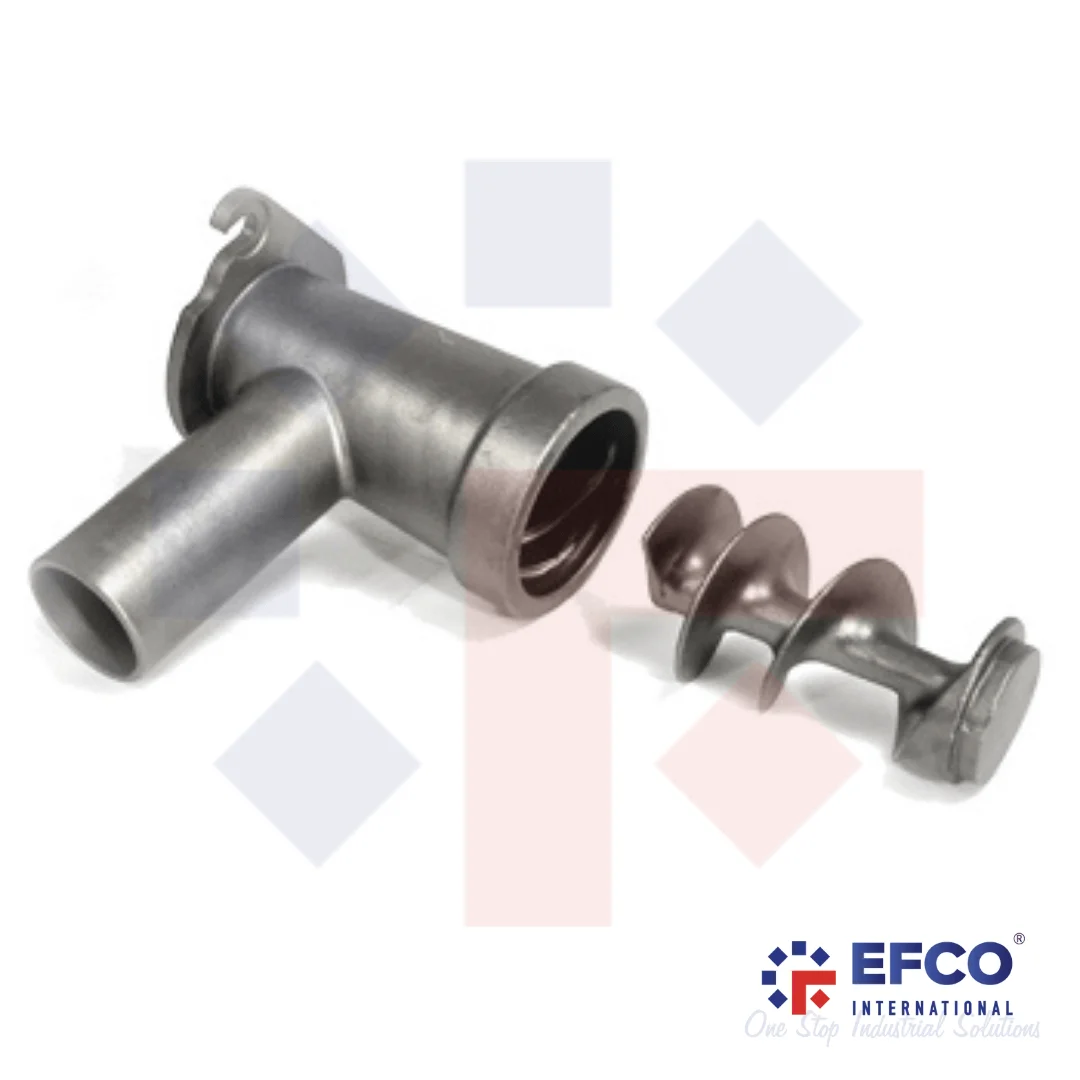

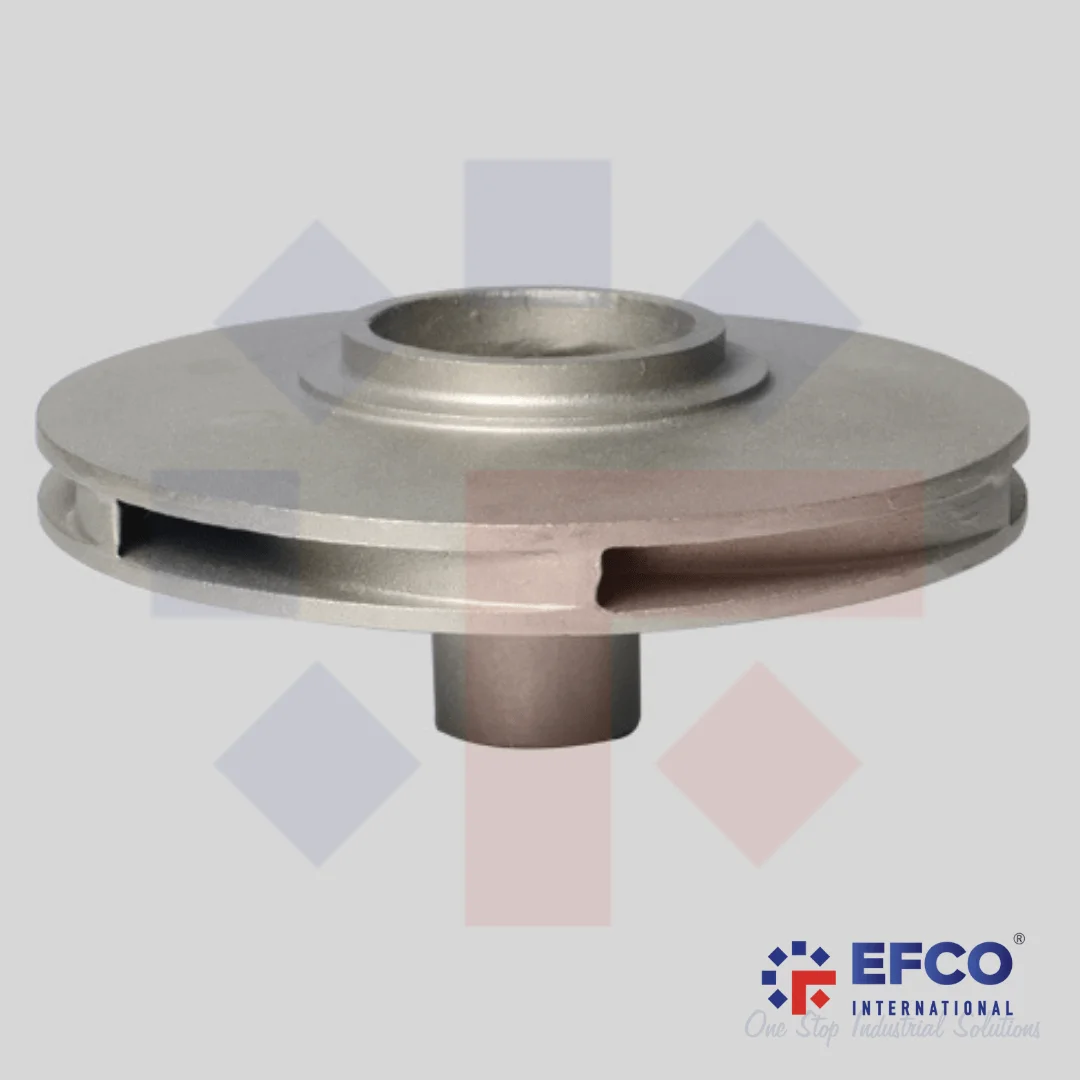

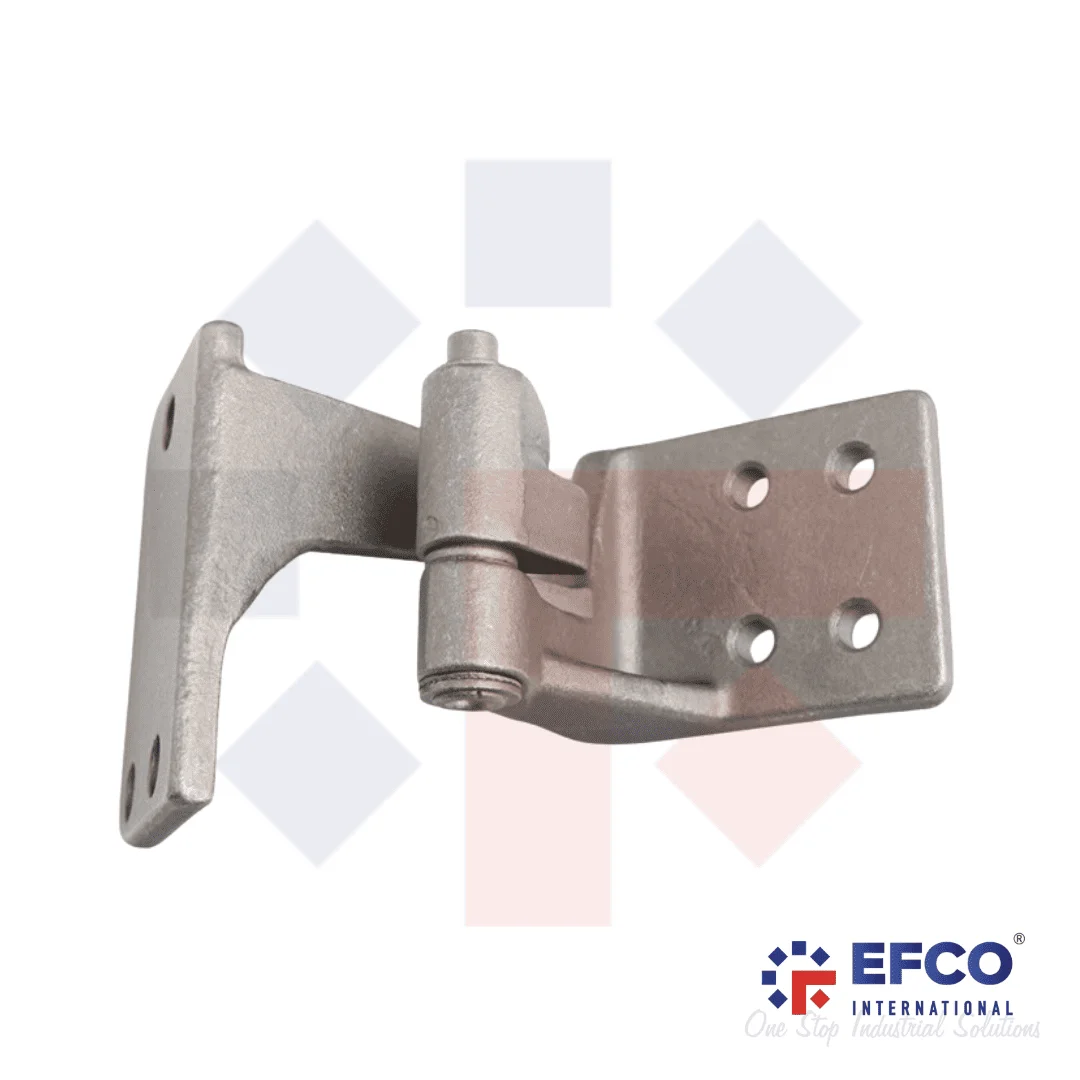

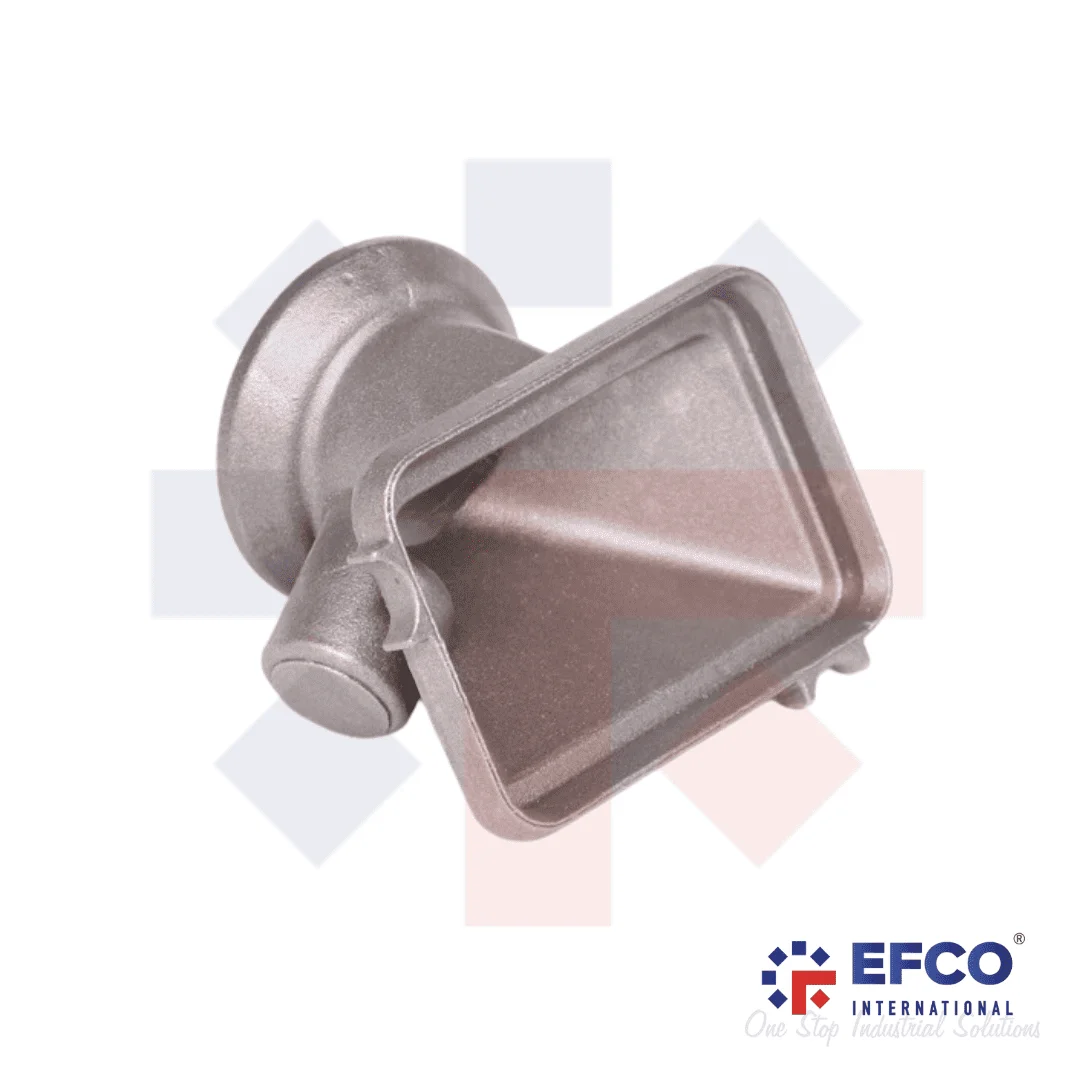

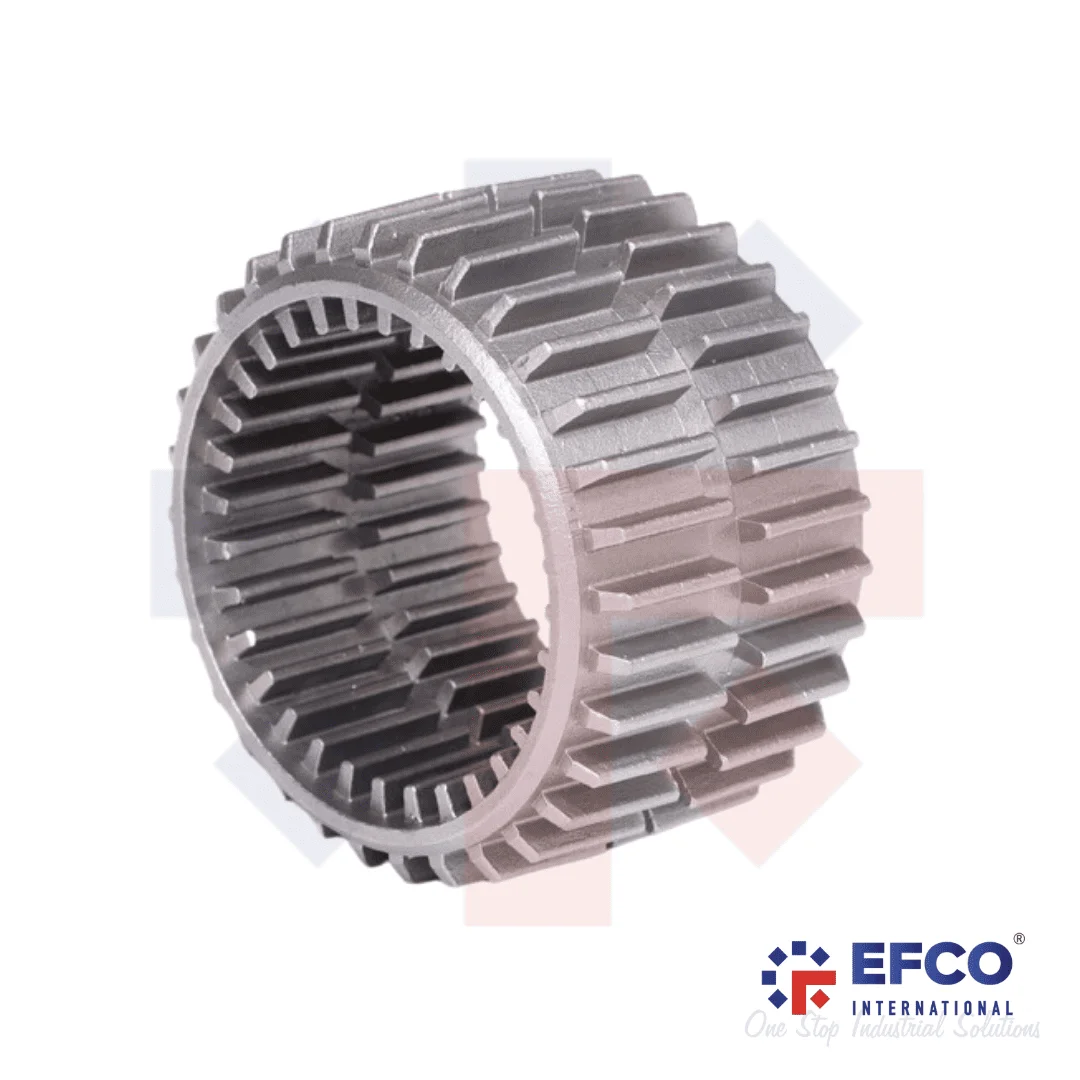

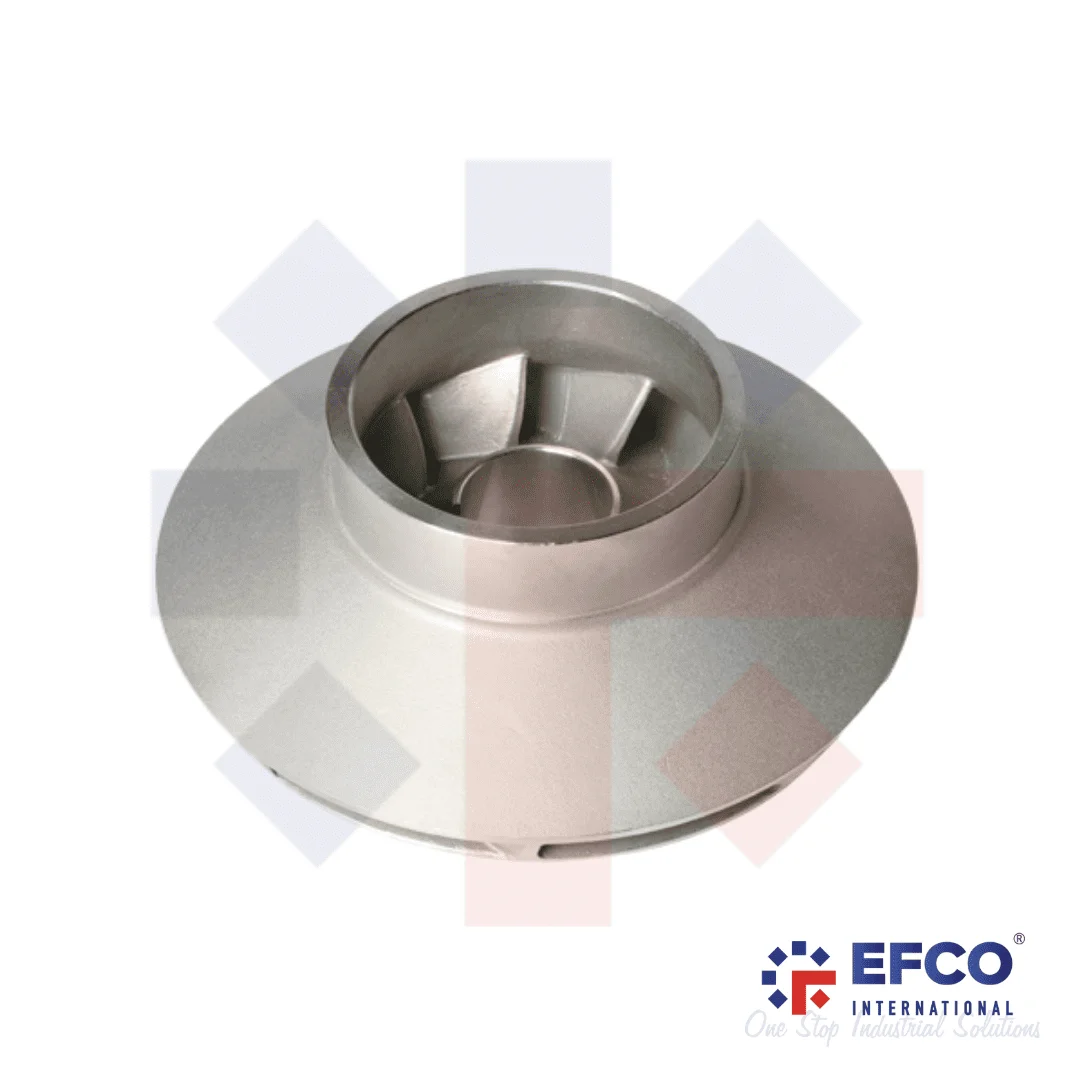

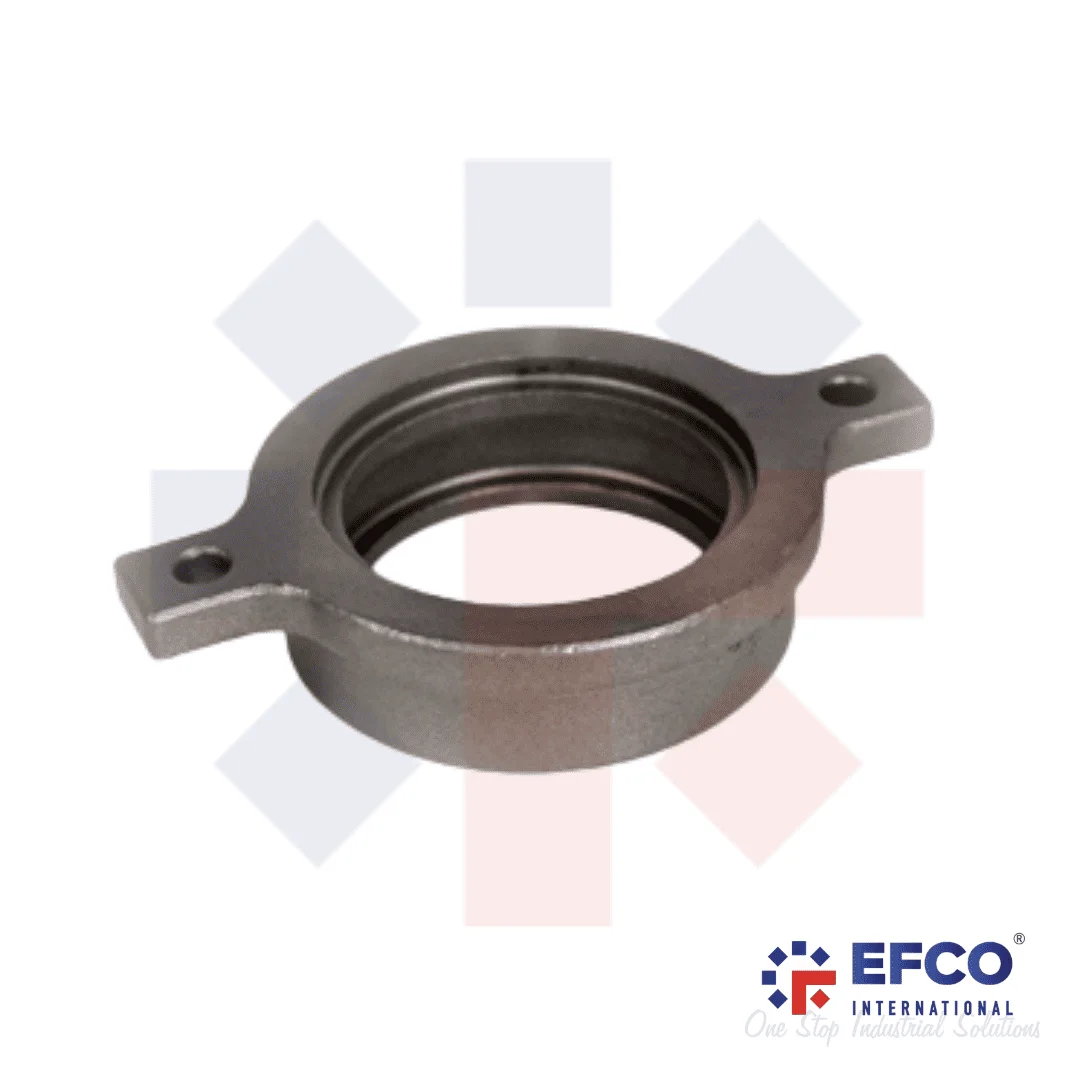

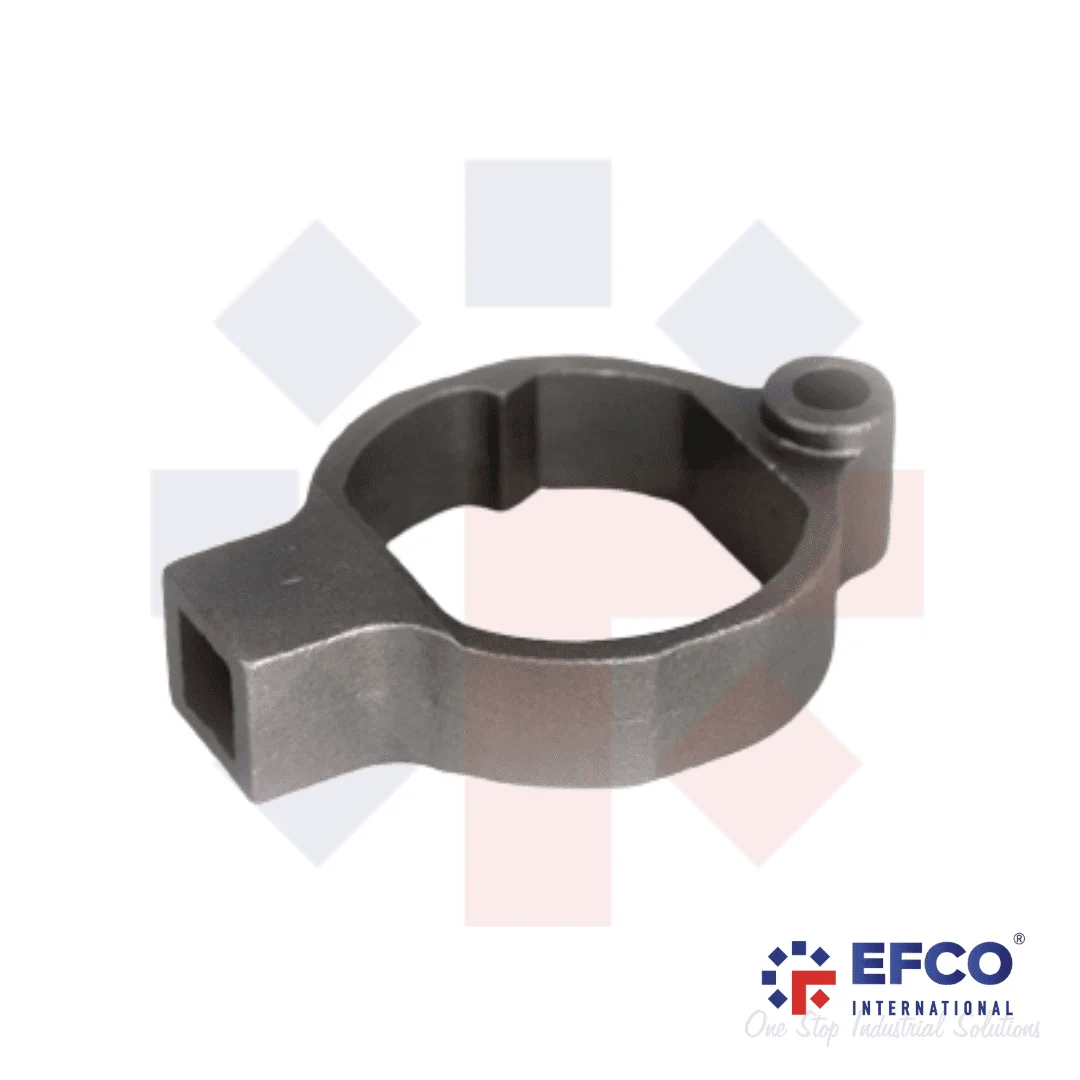

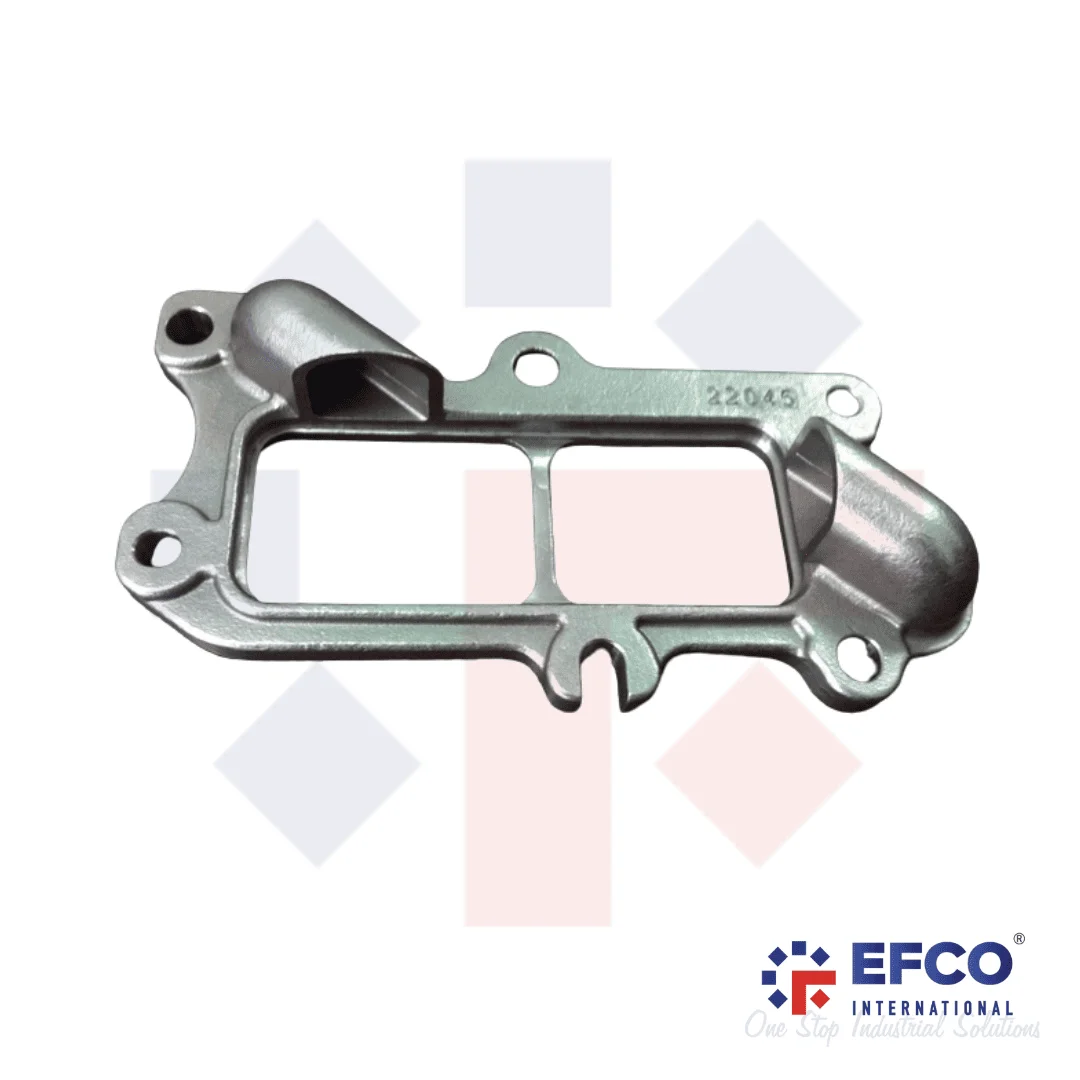

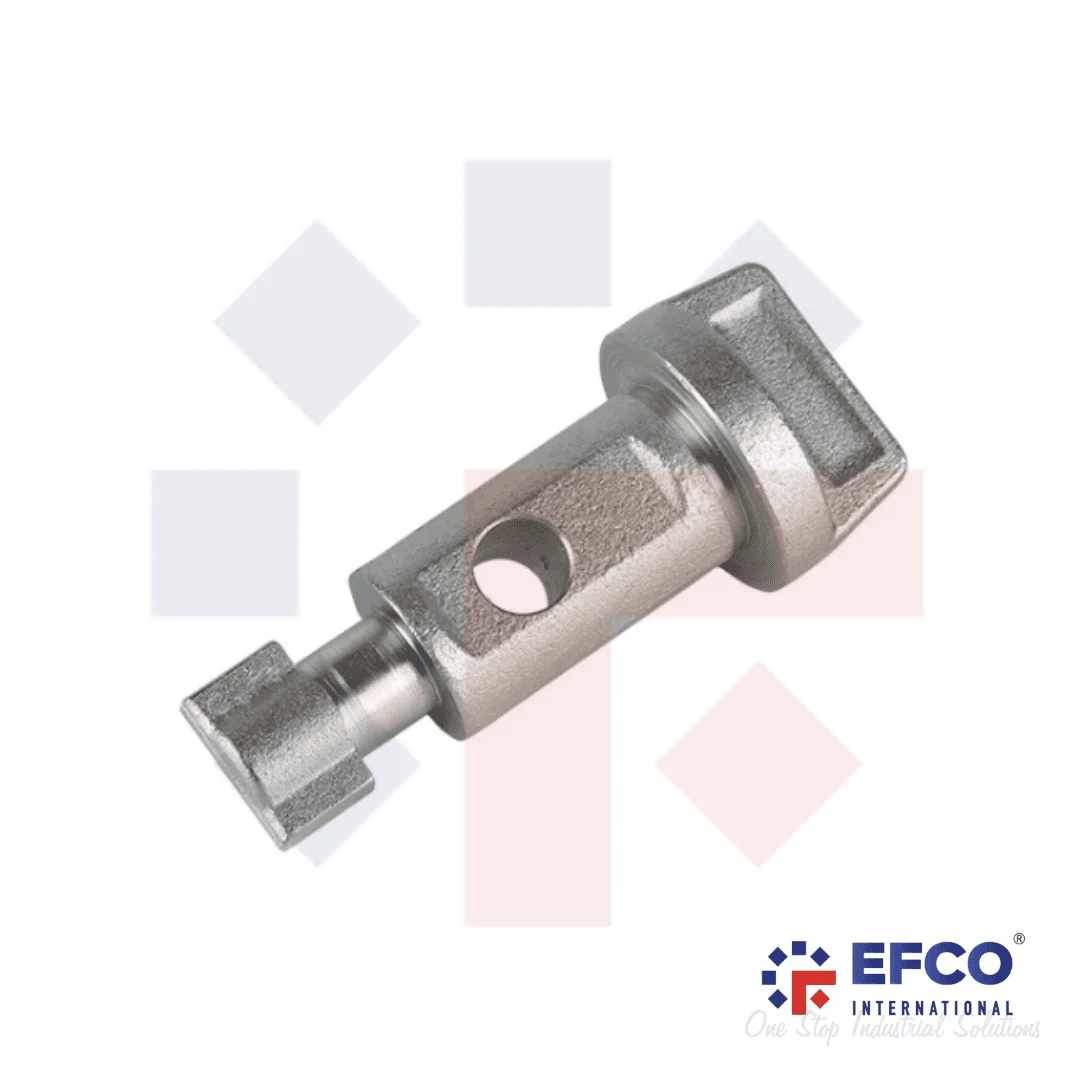

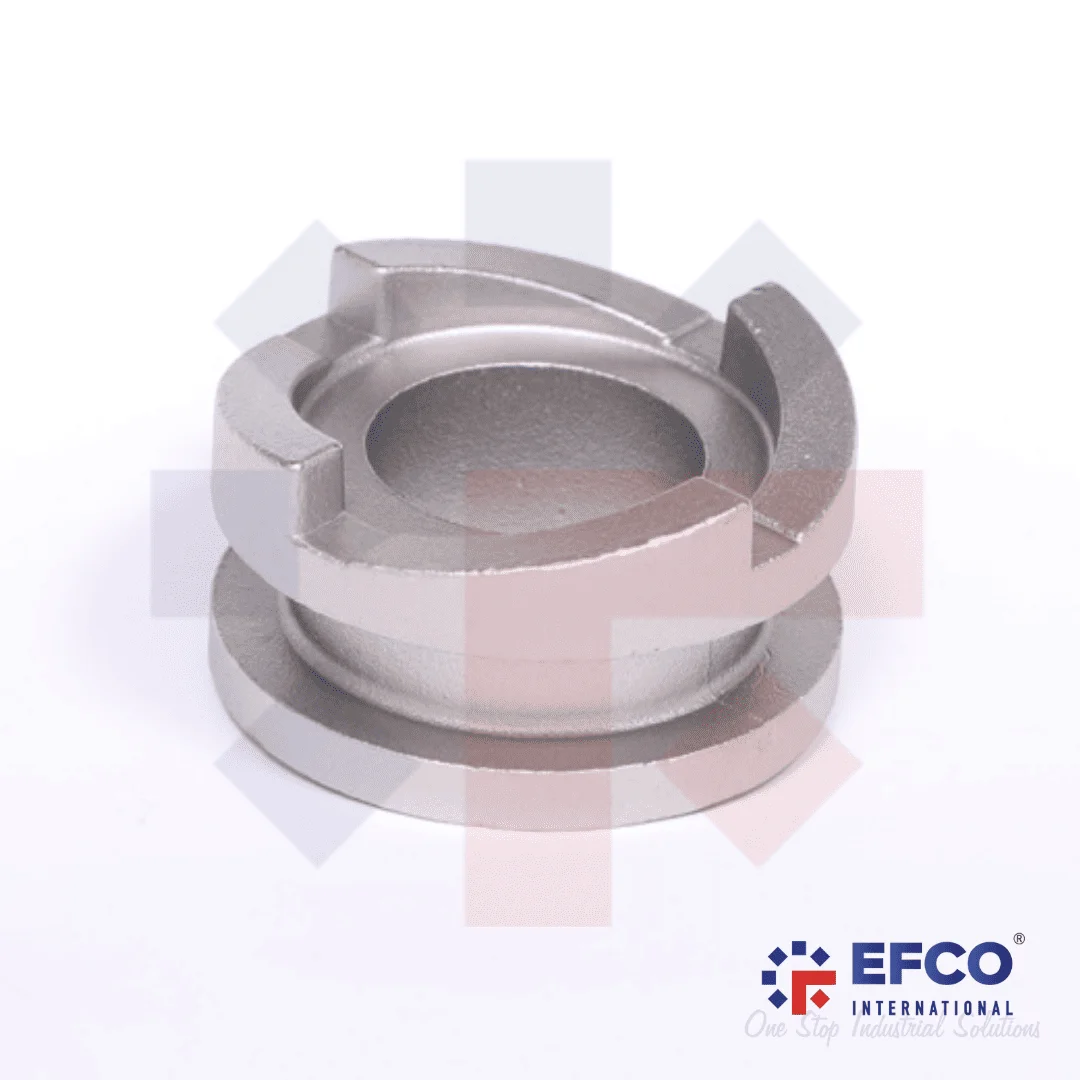

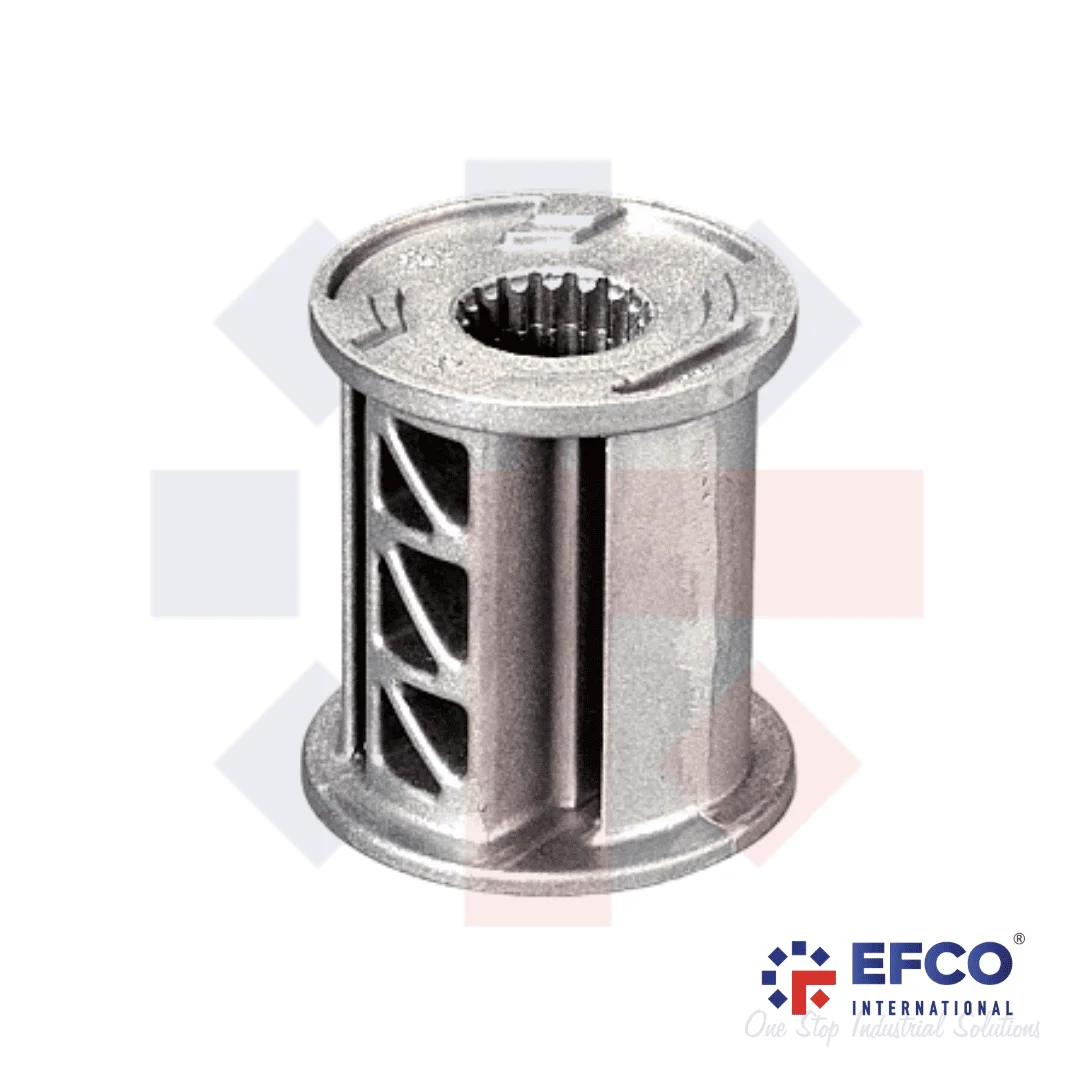

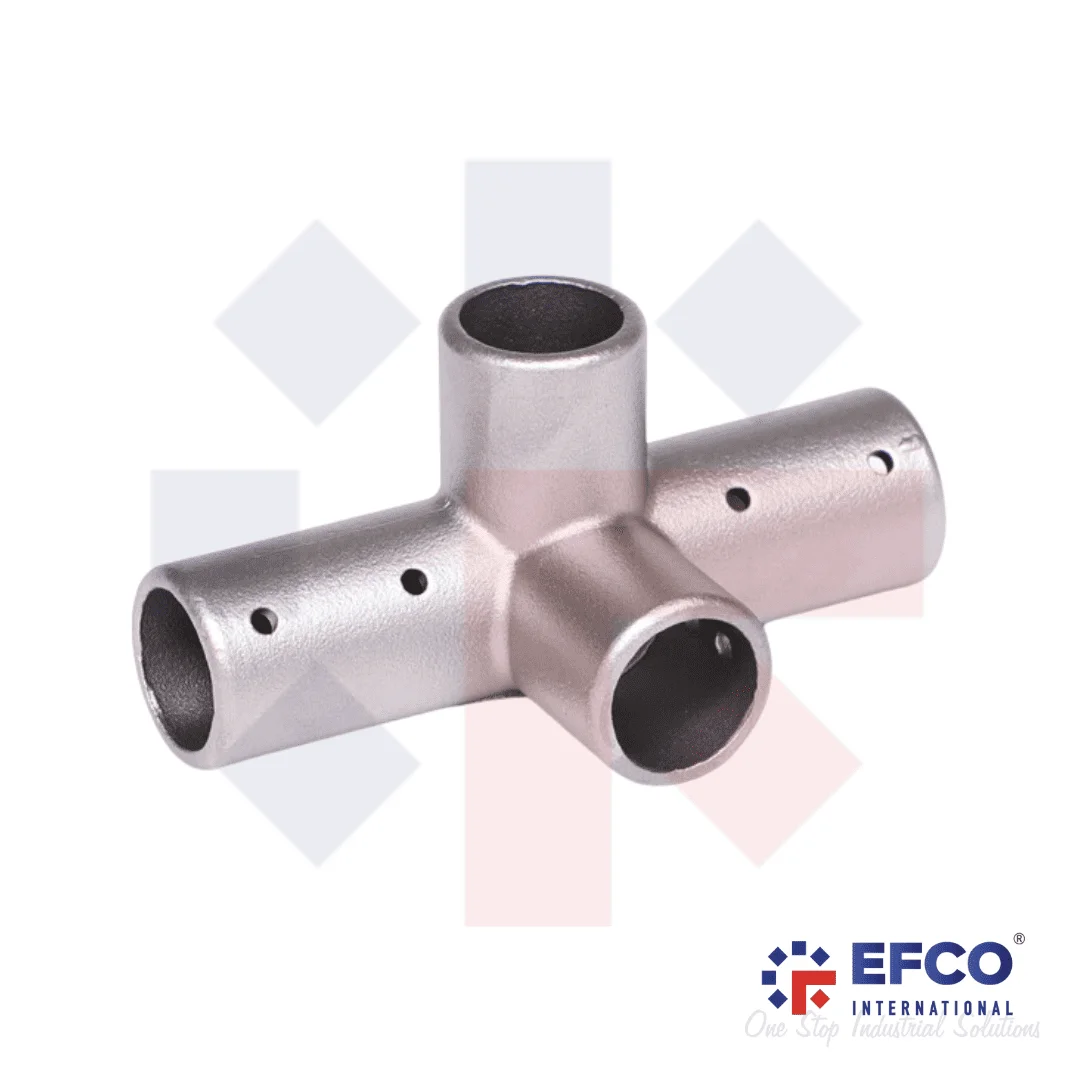

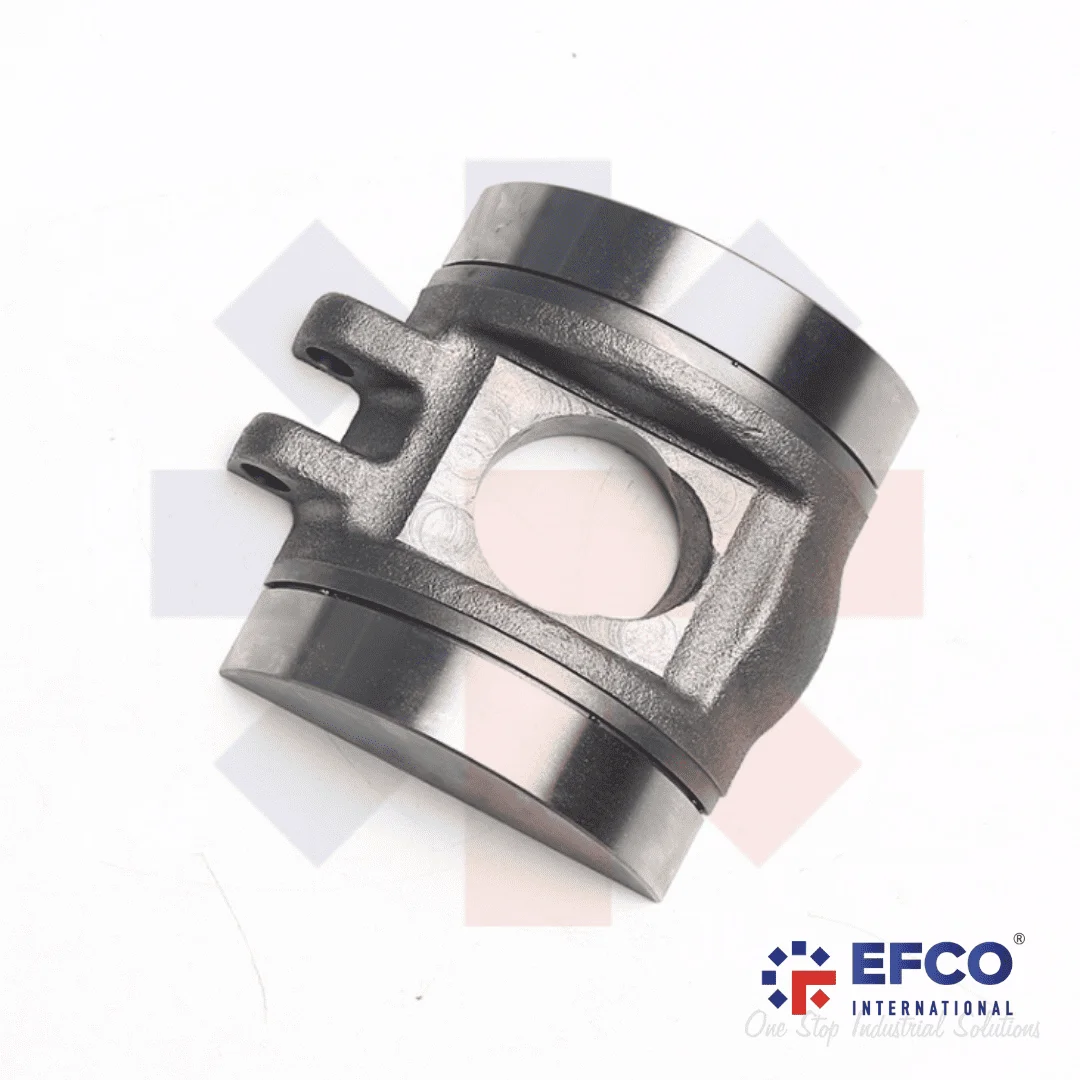

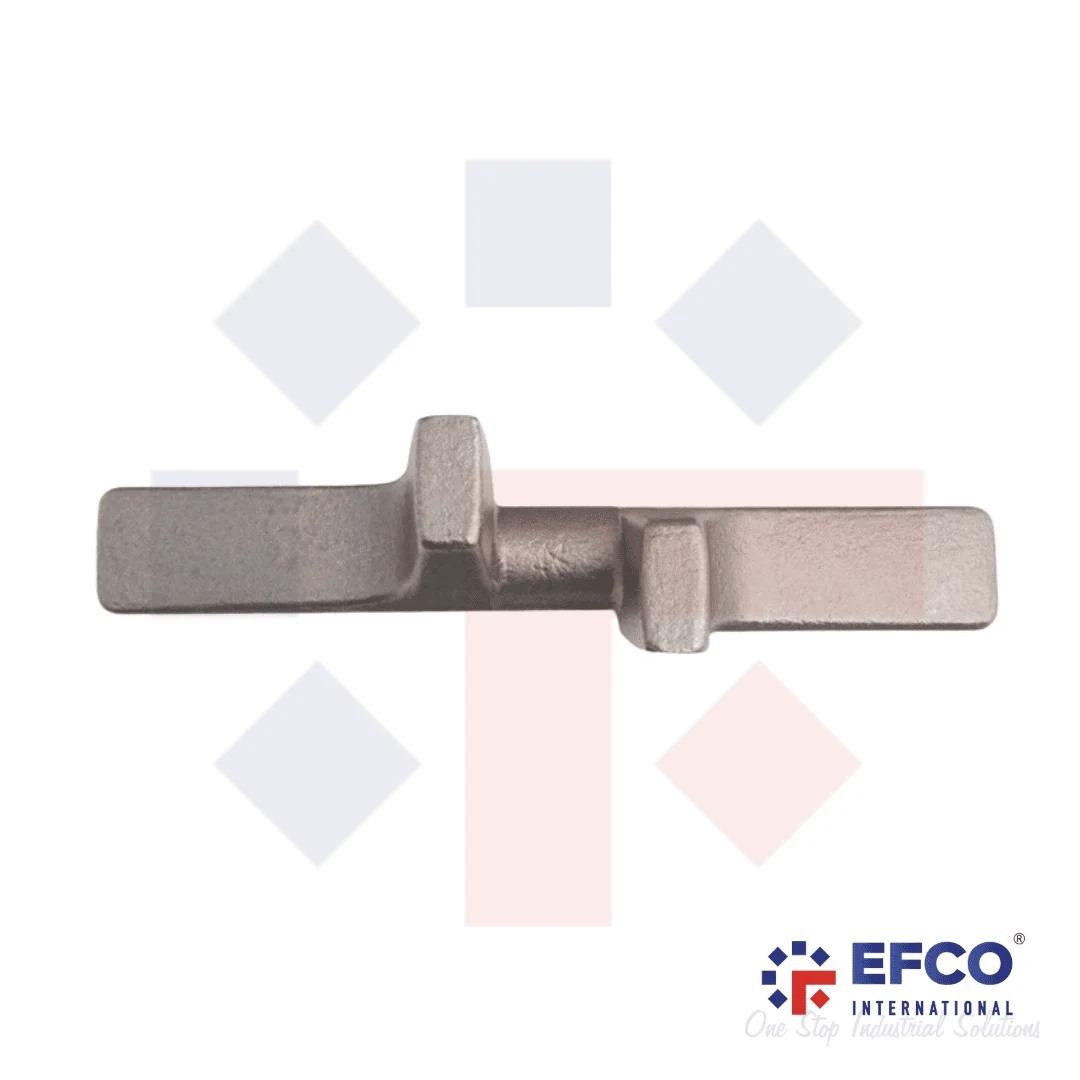

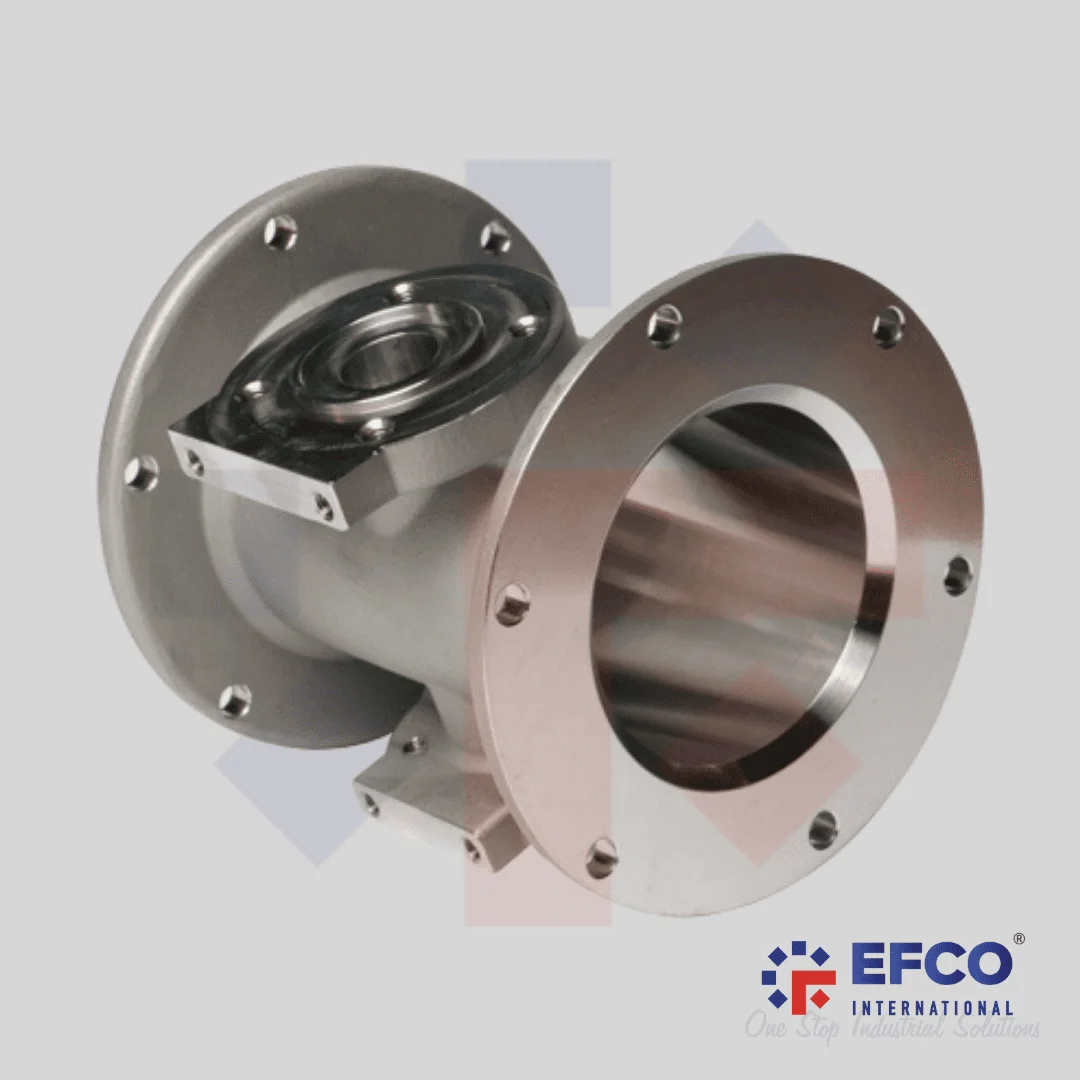

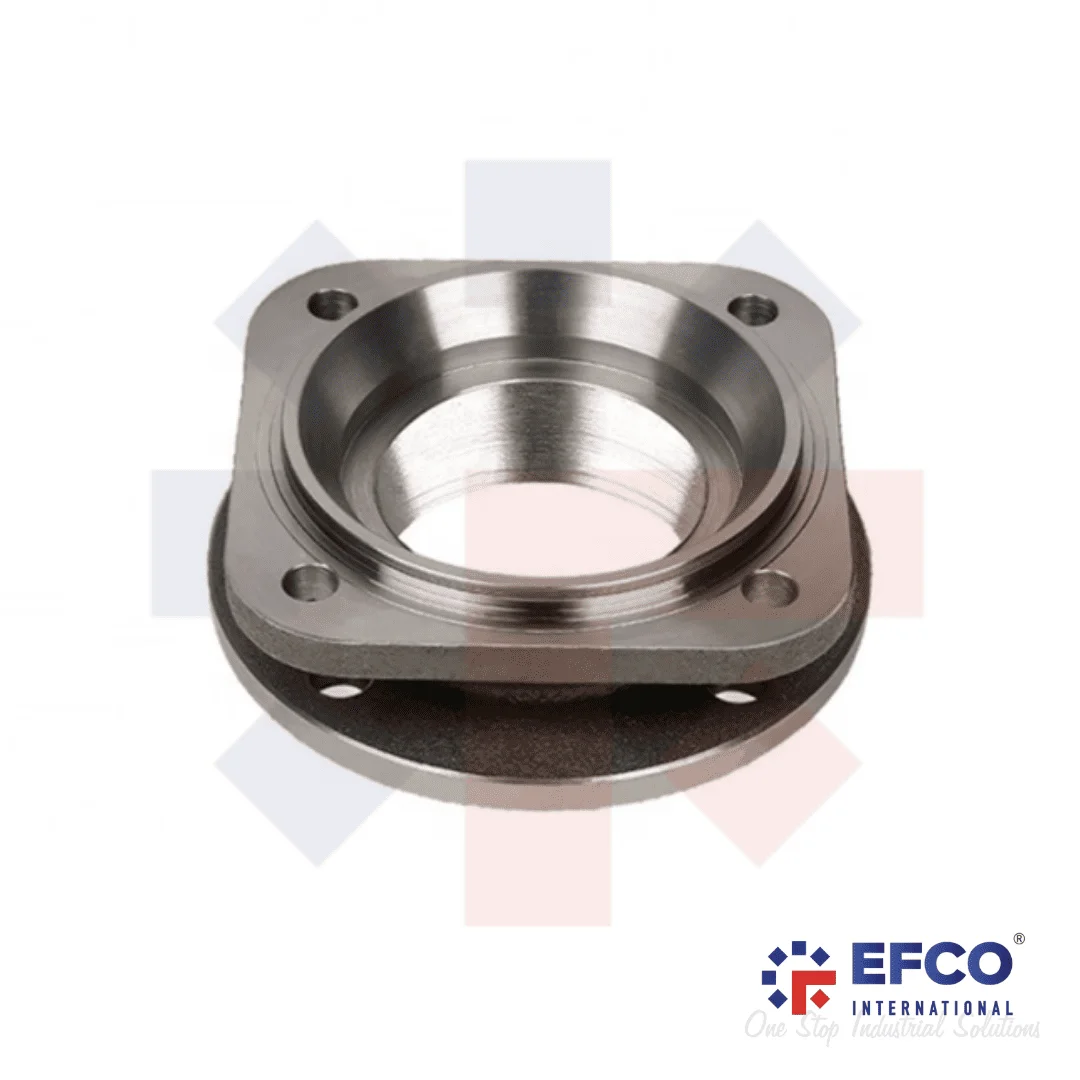

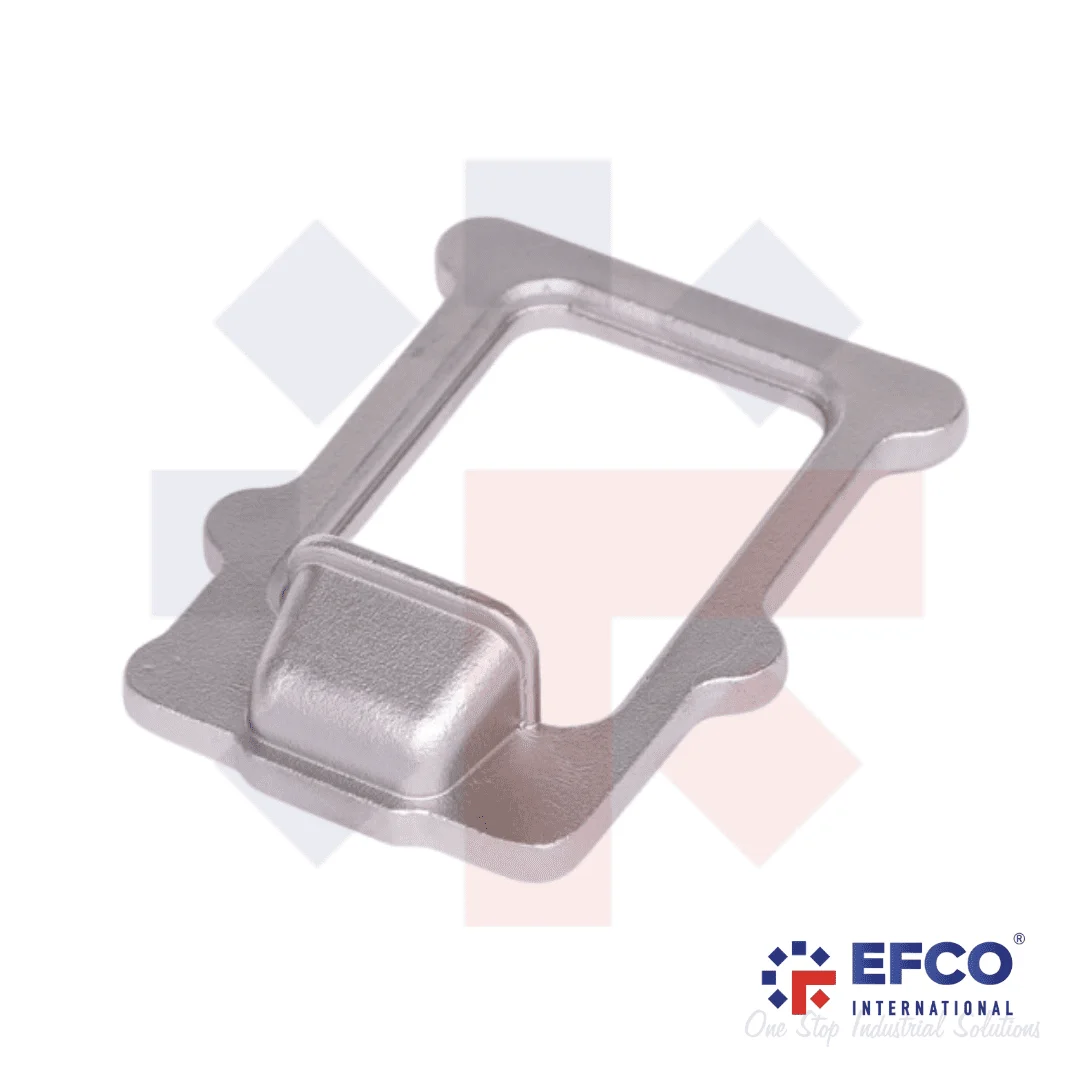

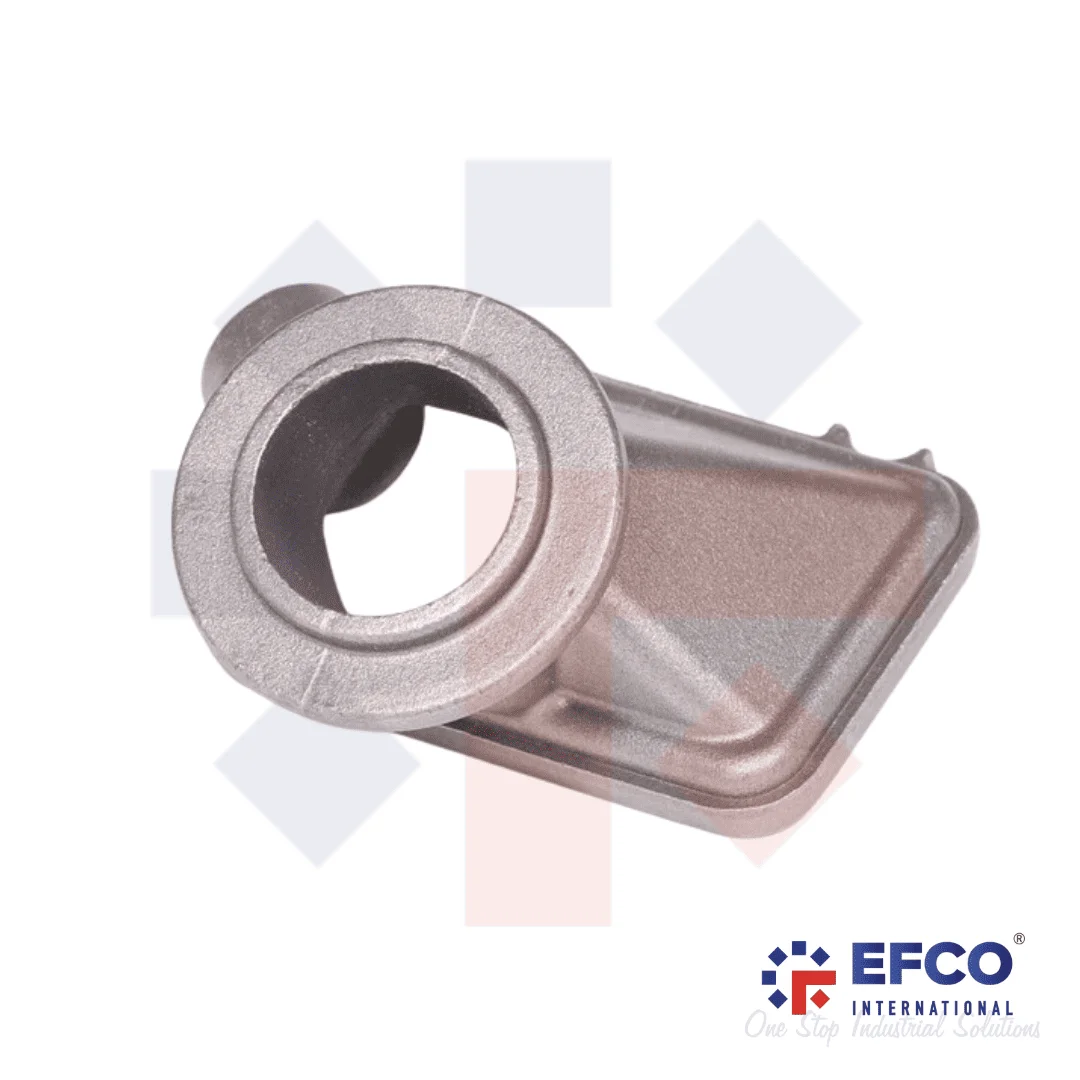

Investment Casting

A wax or plastic model is coated with ceramic; the model is melted out, and molten metal is poured into the cavity. It is preferred for producing parts with tight tolerances, high surface quality, and complex geometries.

Materials Used: Stainless steel, carbon steel, alloy steels, nickel/cobalt-based superalloys, aluminum

Subtypes: Water Glass, Silica Sol, Hybrid (Water Glass + Silica Sol), Ceramic Shell

Specifications and Tolerances

-

Standards: ISO 8062, ASTM A356, ASTM E446 (NDT)

-

Dimensional tolerance: ISO 8062 CT4 – CT6 (±0.3 – 0.6 mm)

-

Surface roughness: Ra 1.6 – 6.3 µm

Applications

-

Aerospace and defense: turbine blades, rocket and missile components, weapon mechanisms

-

Automotive: valve components, gears, fasteners

-

Medical: orthopedic implants, surgical instruments

-

Industrial: machine parts and industrial components

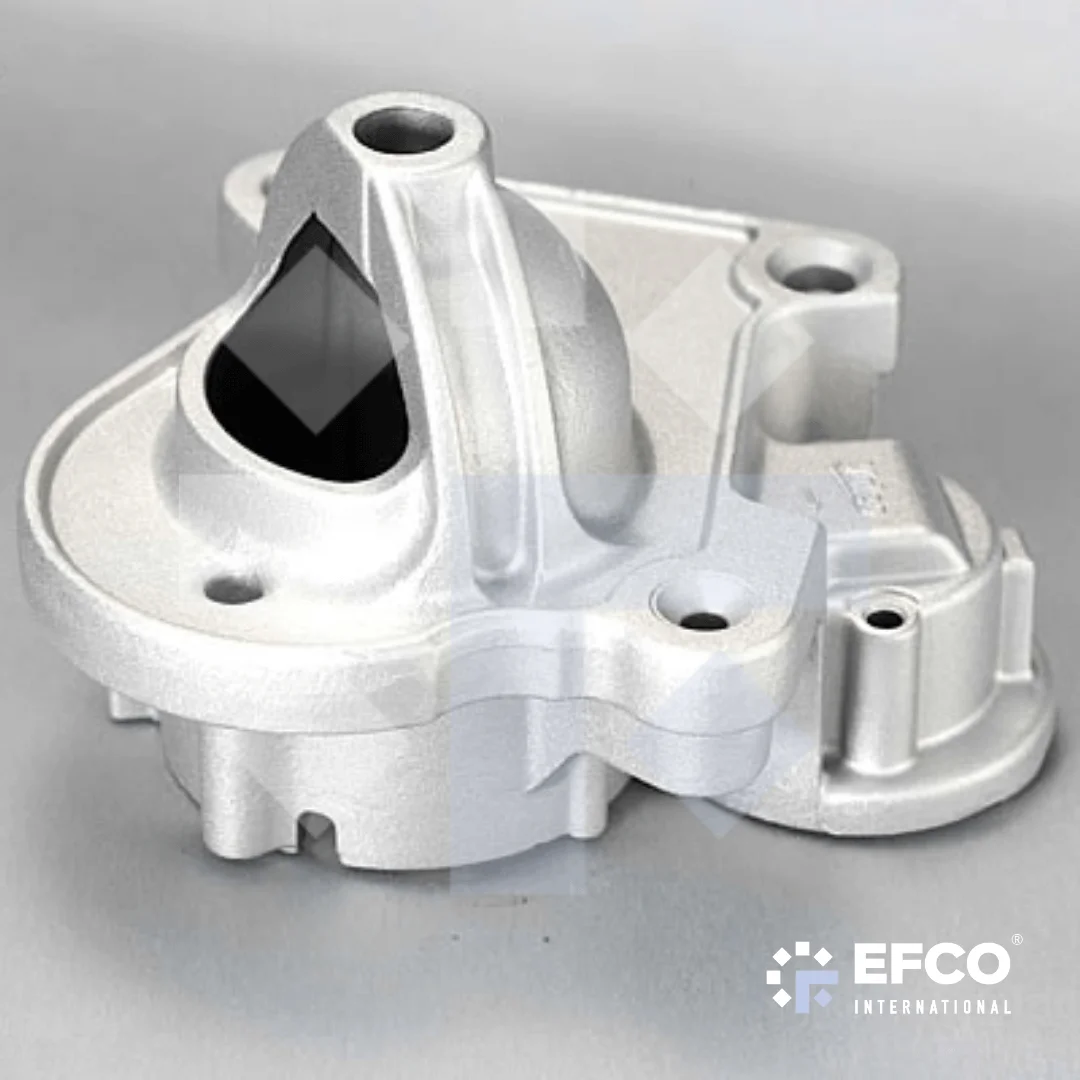

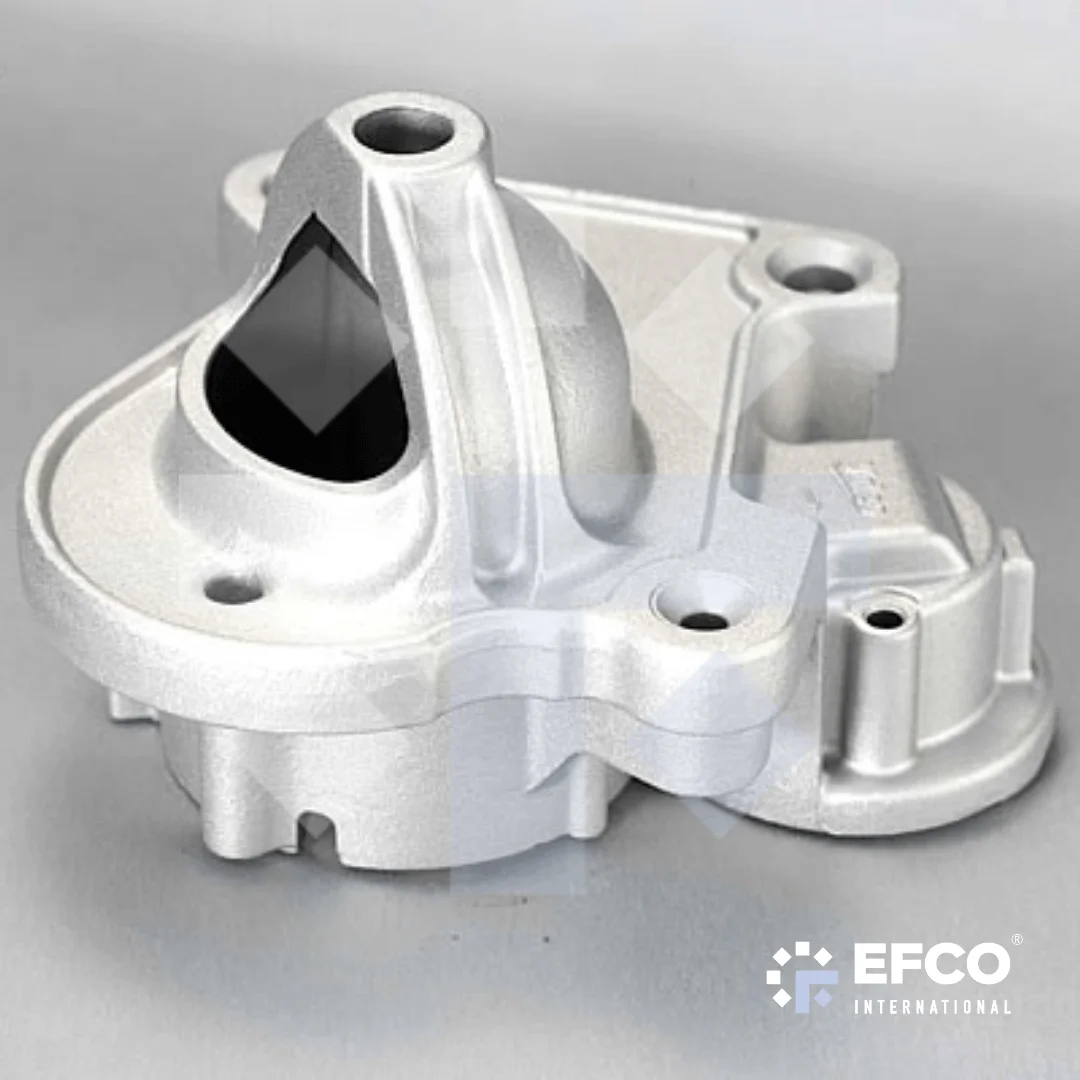

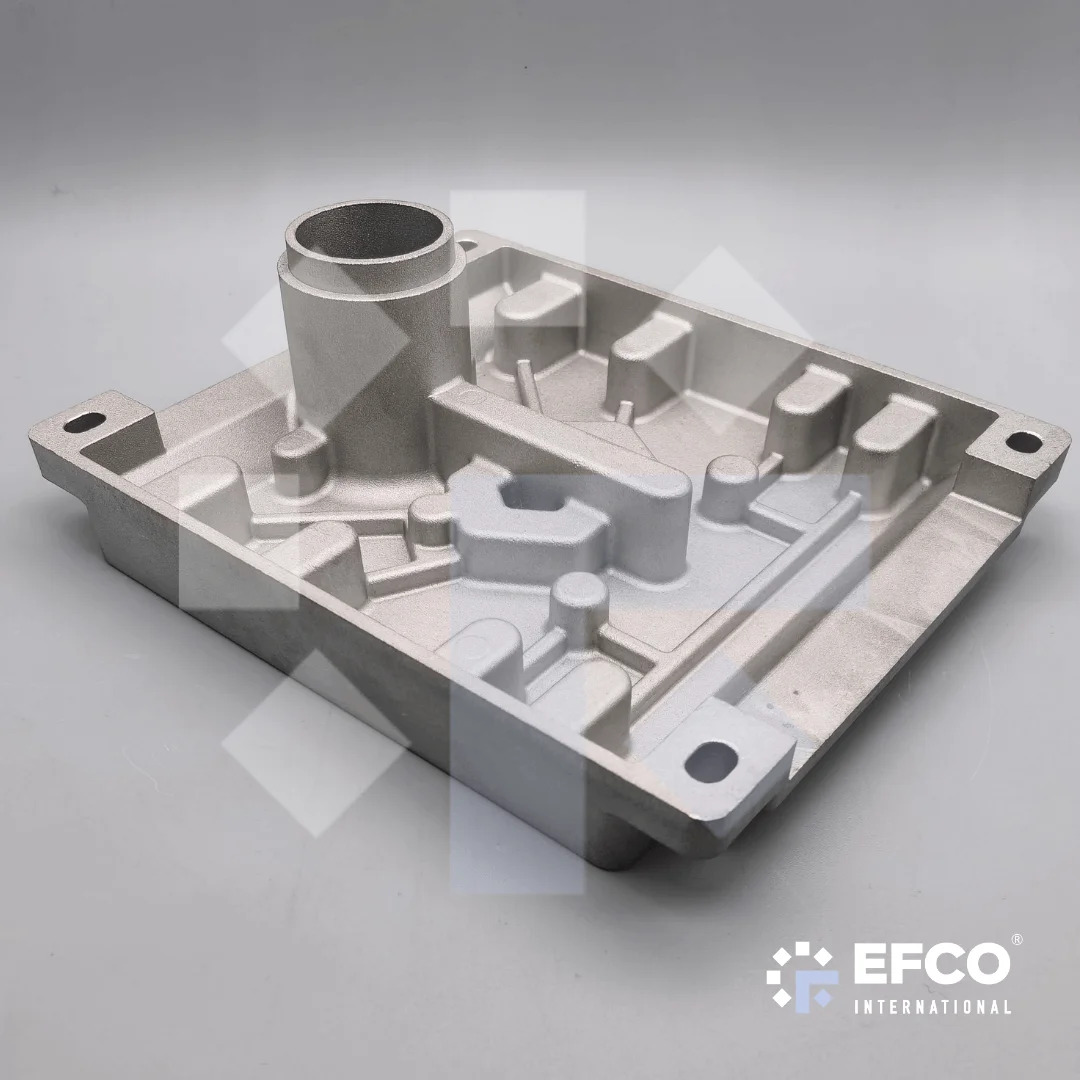

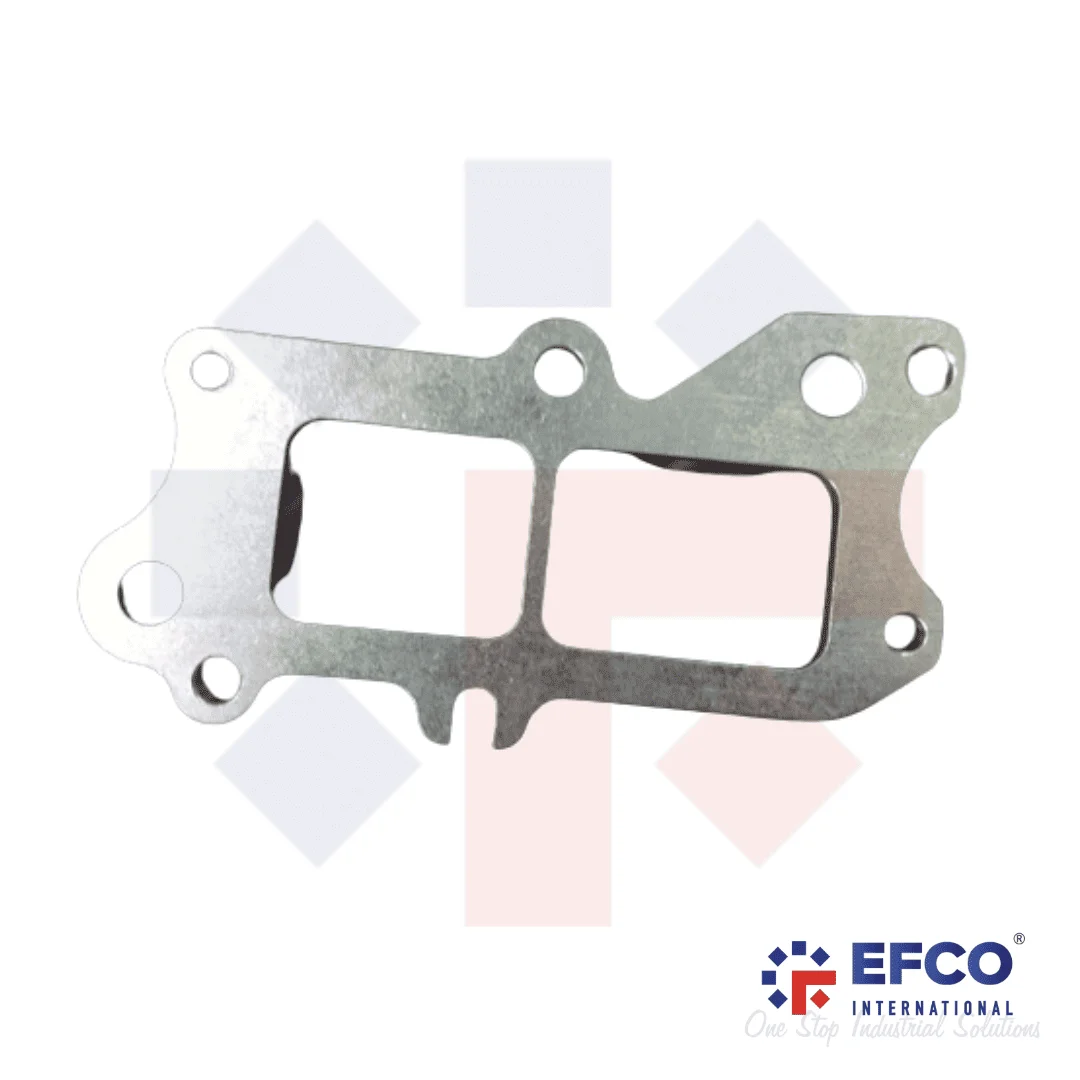

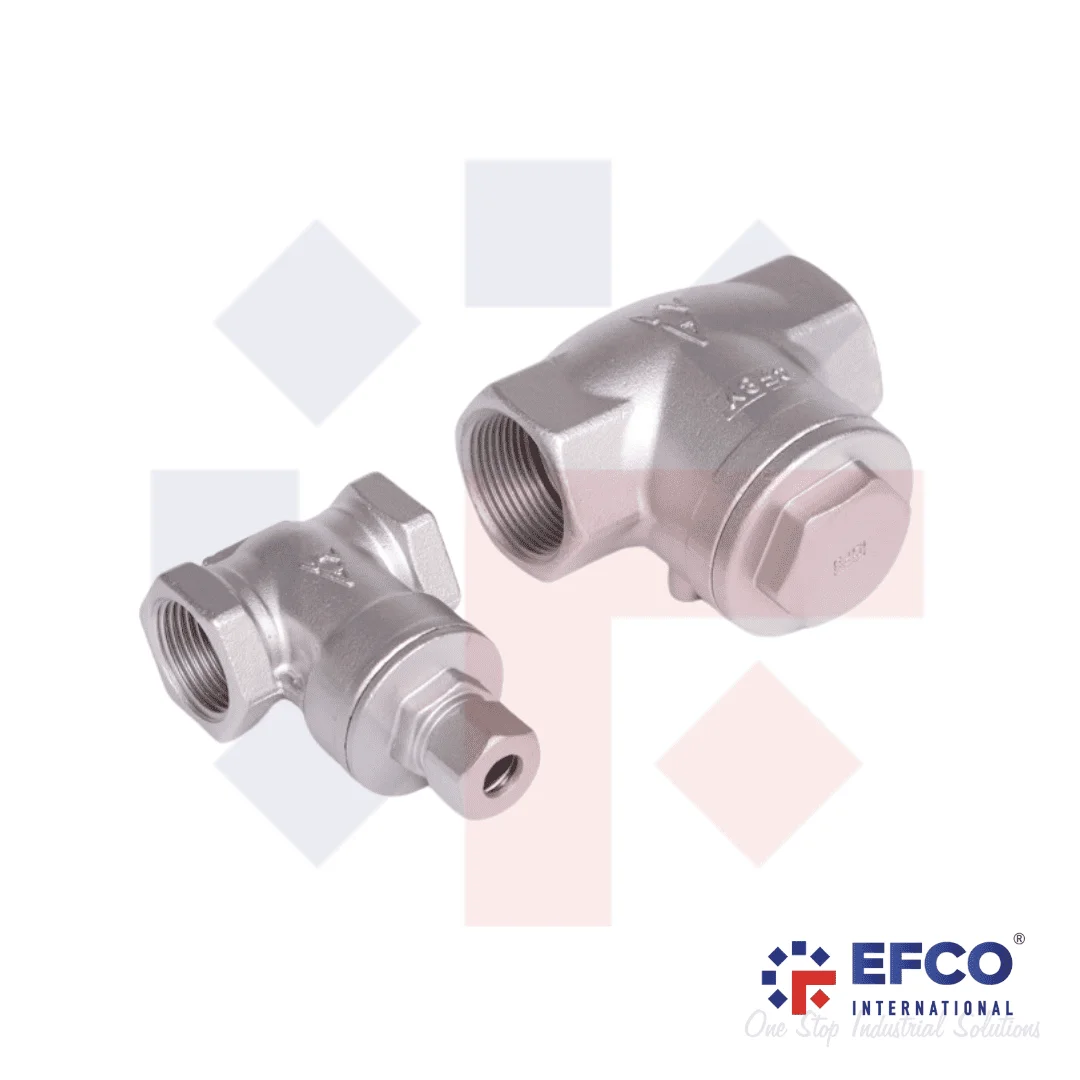

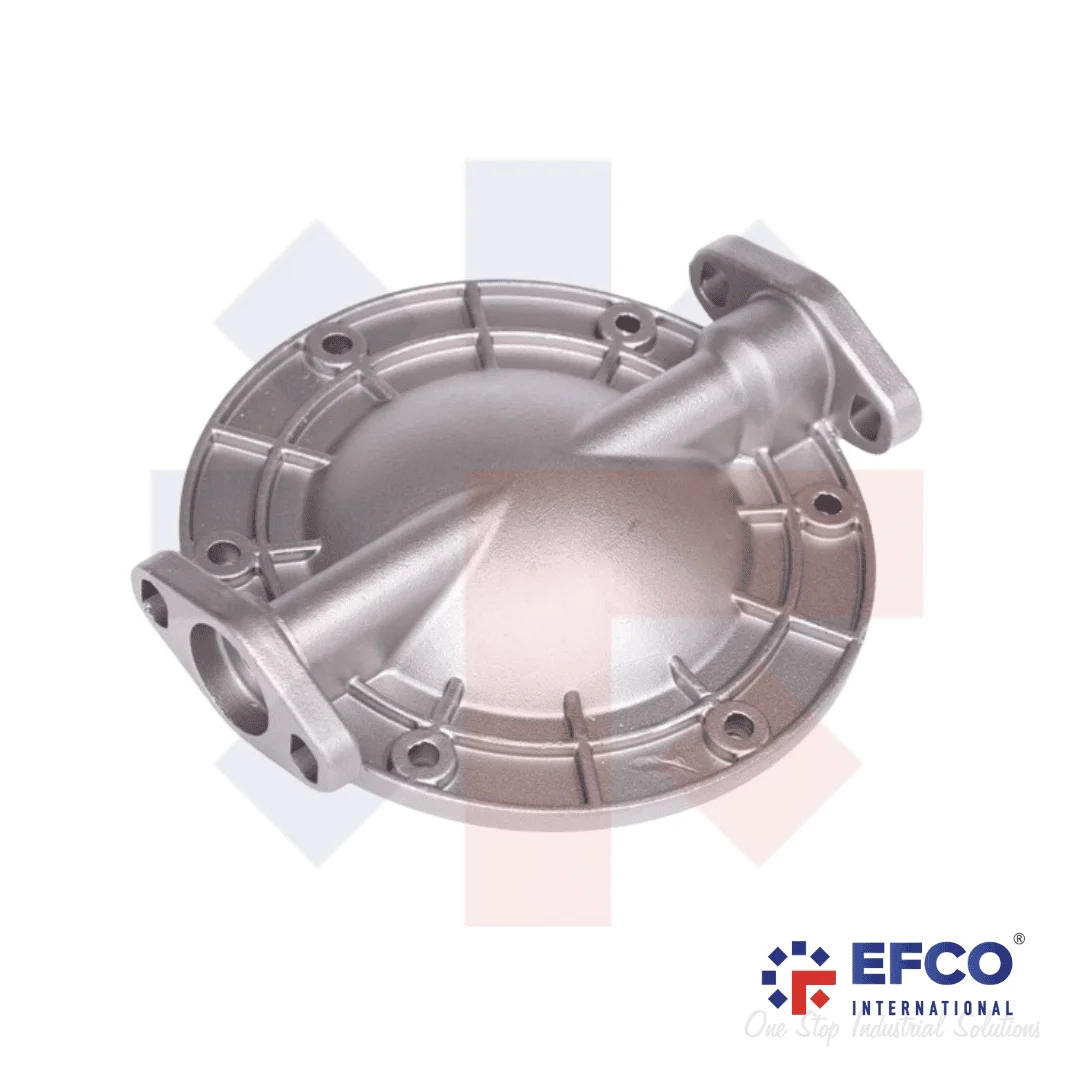

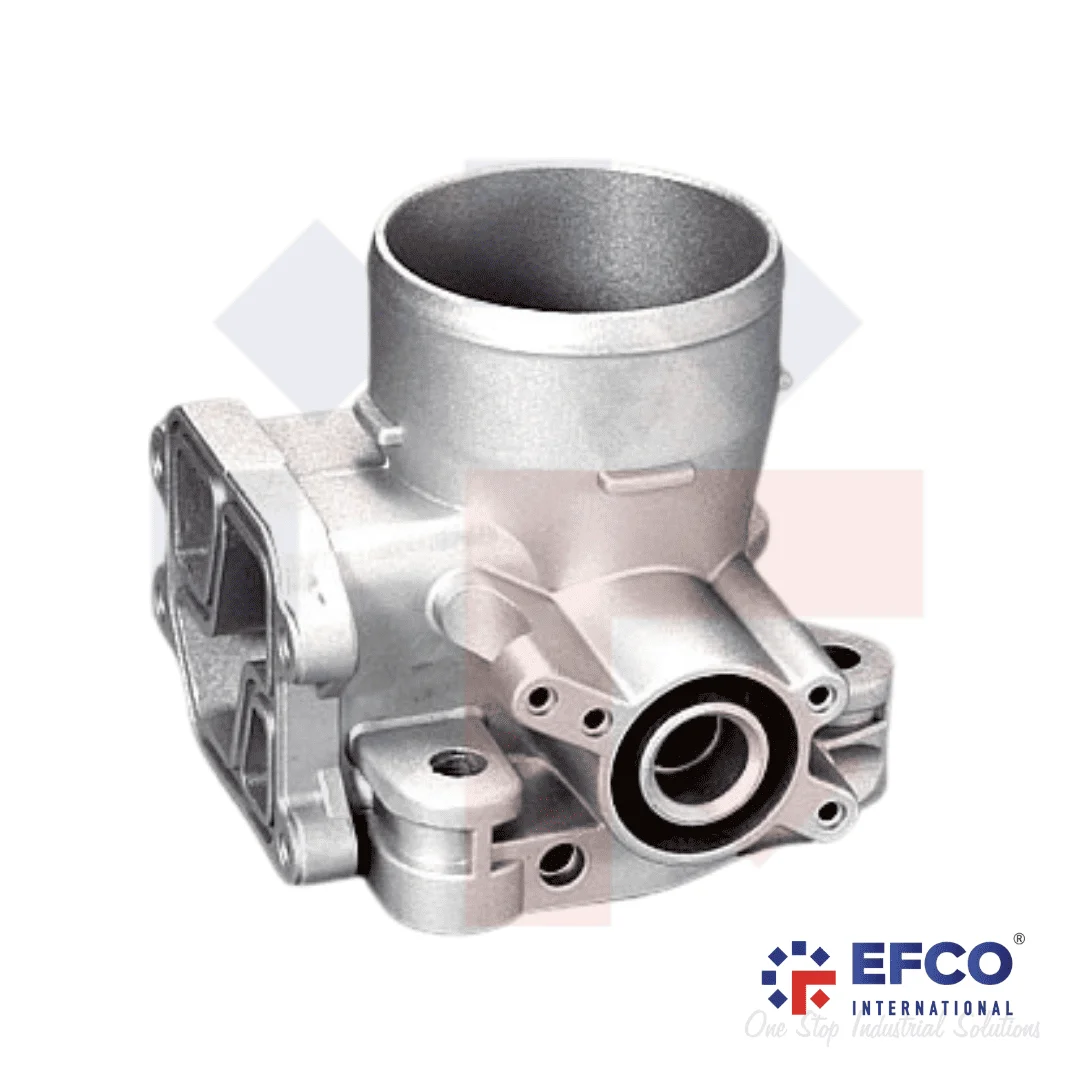

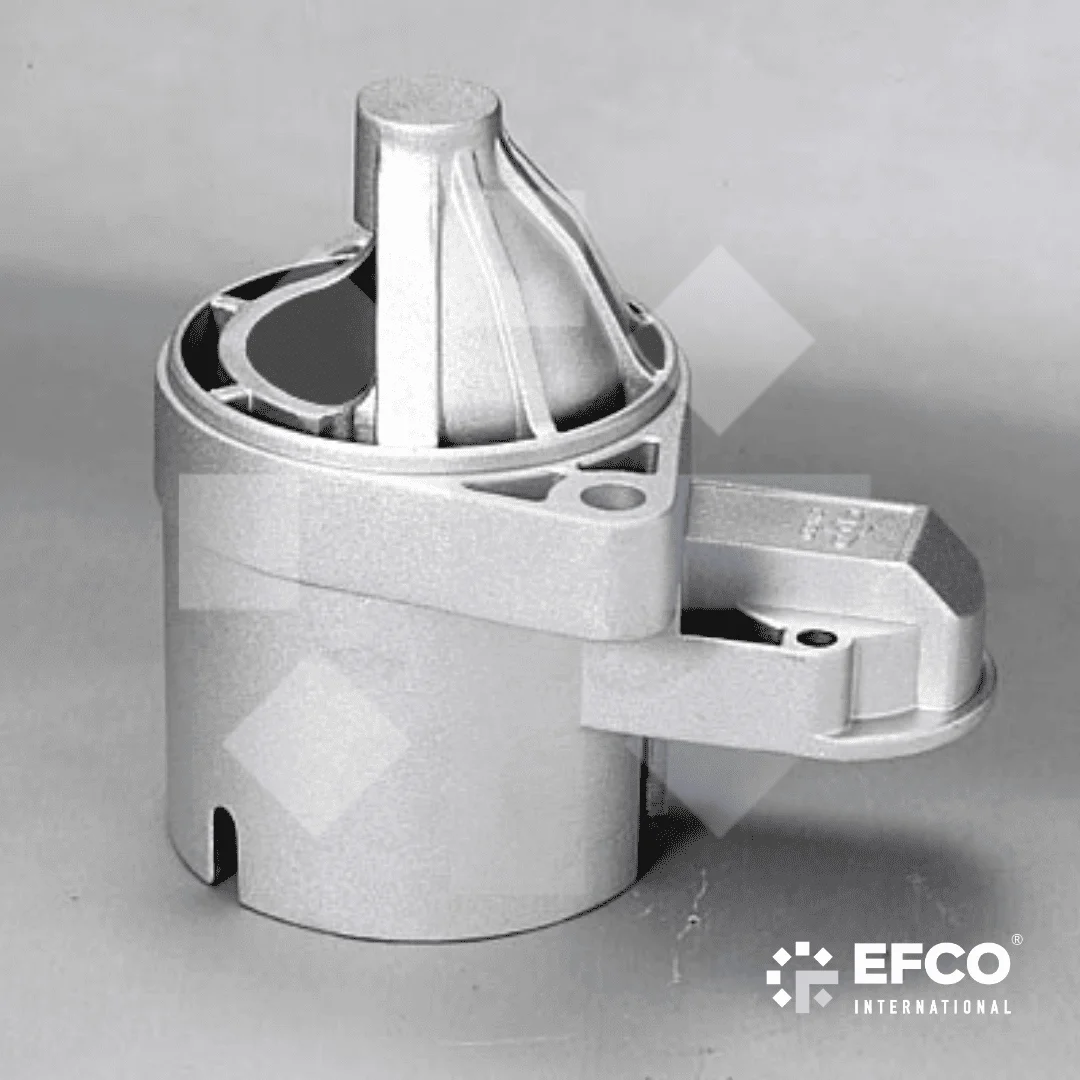

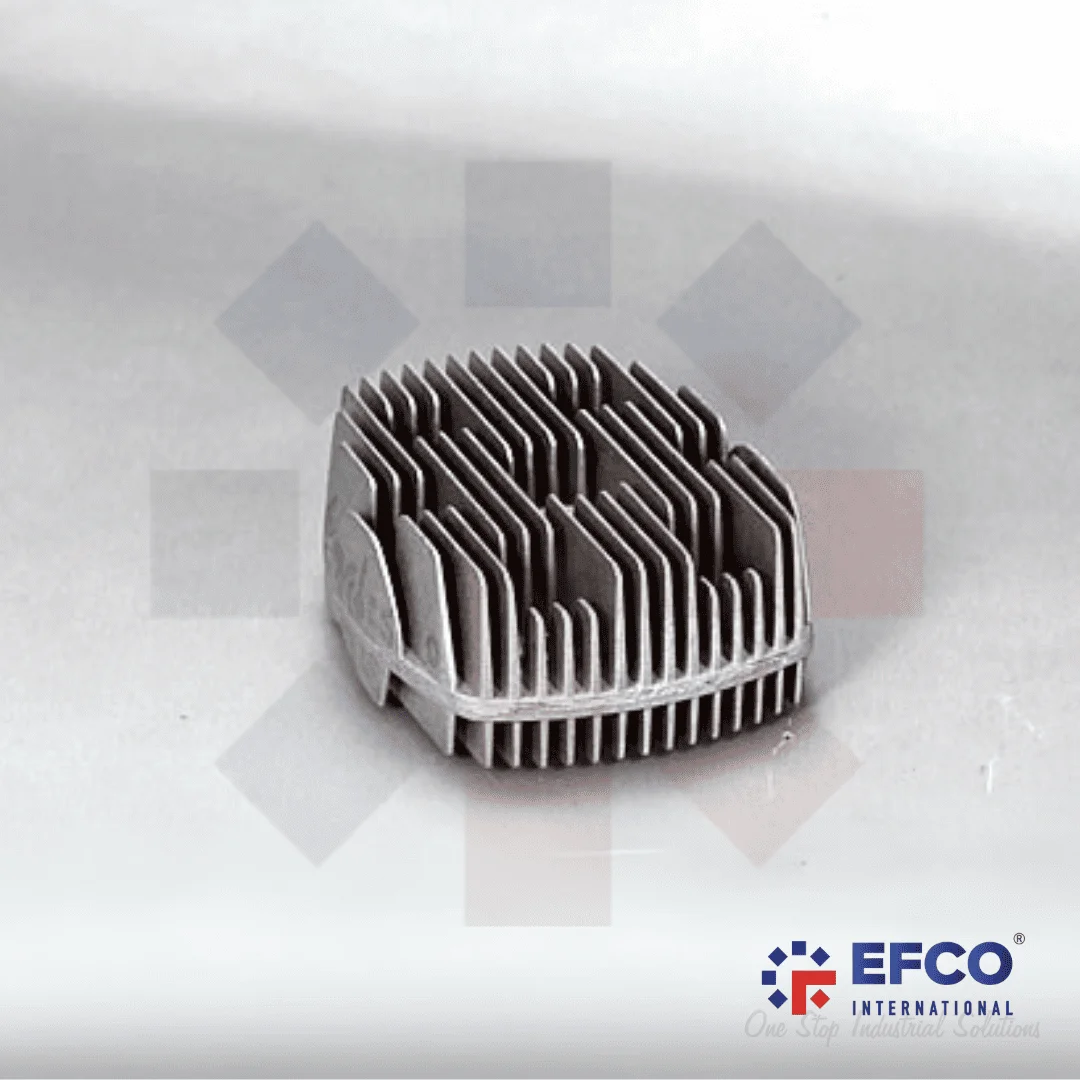

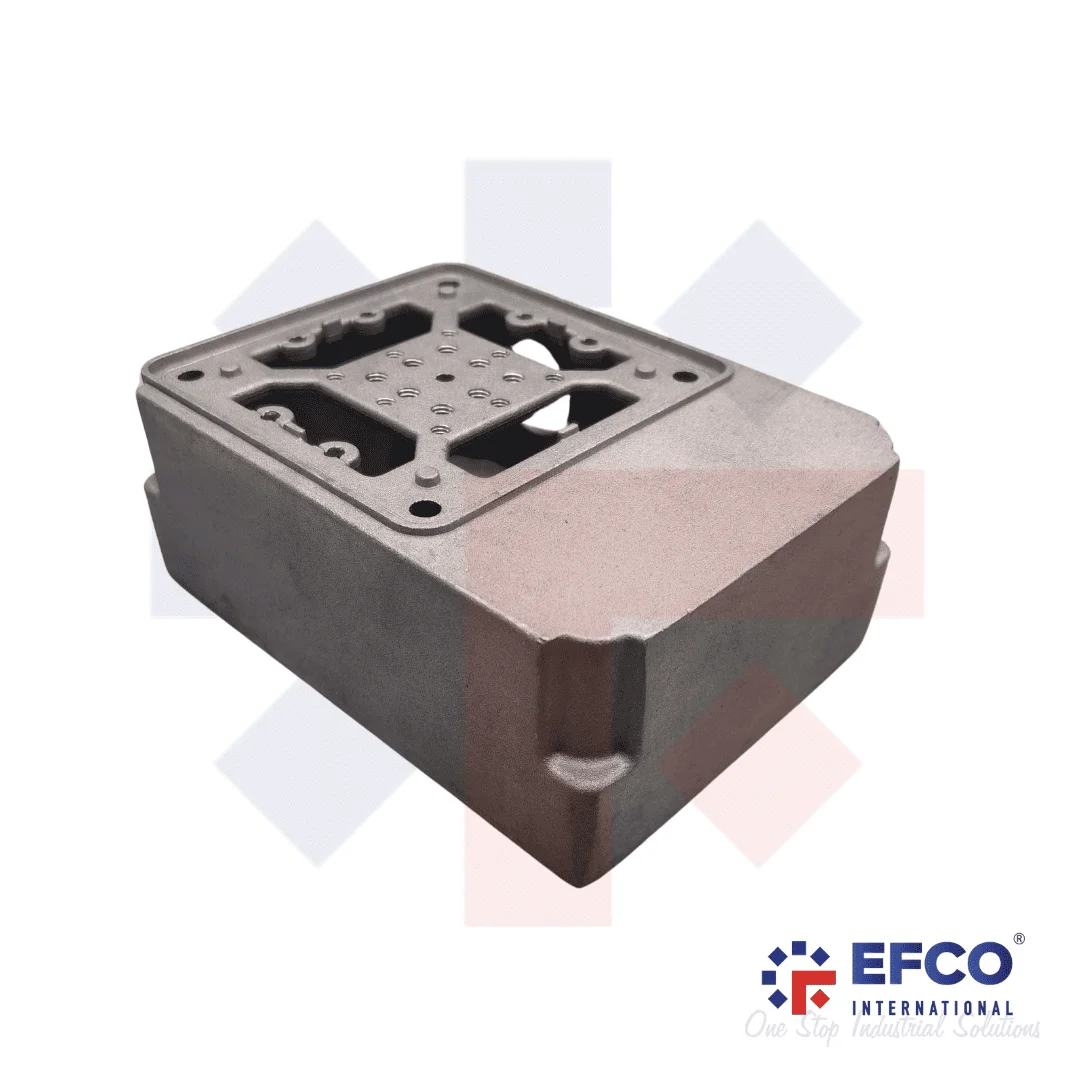

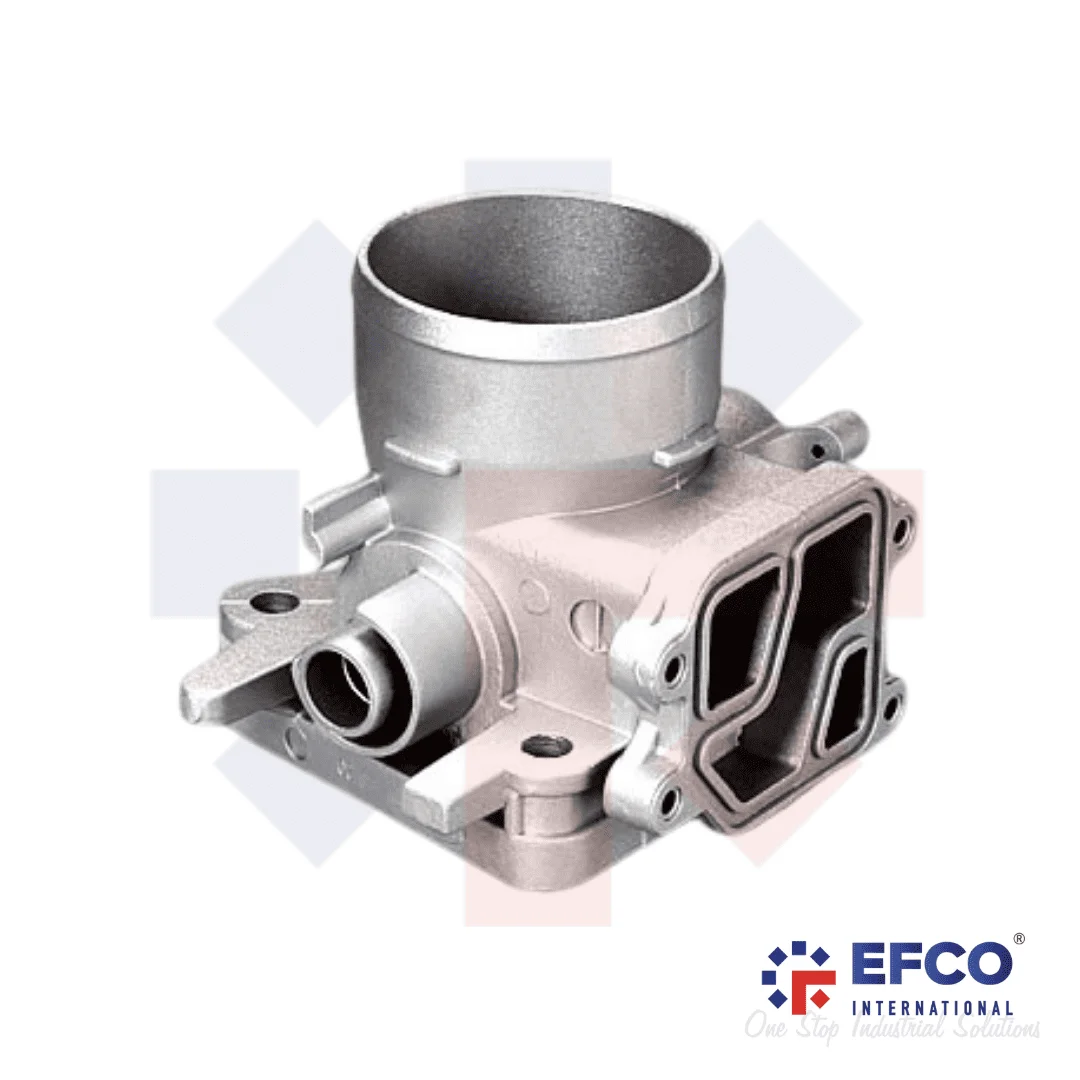

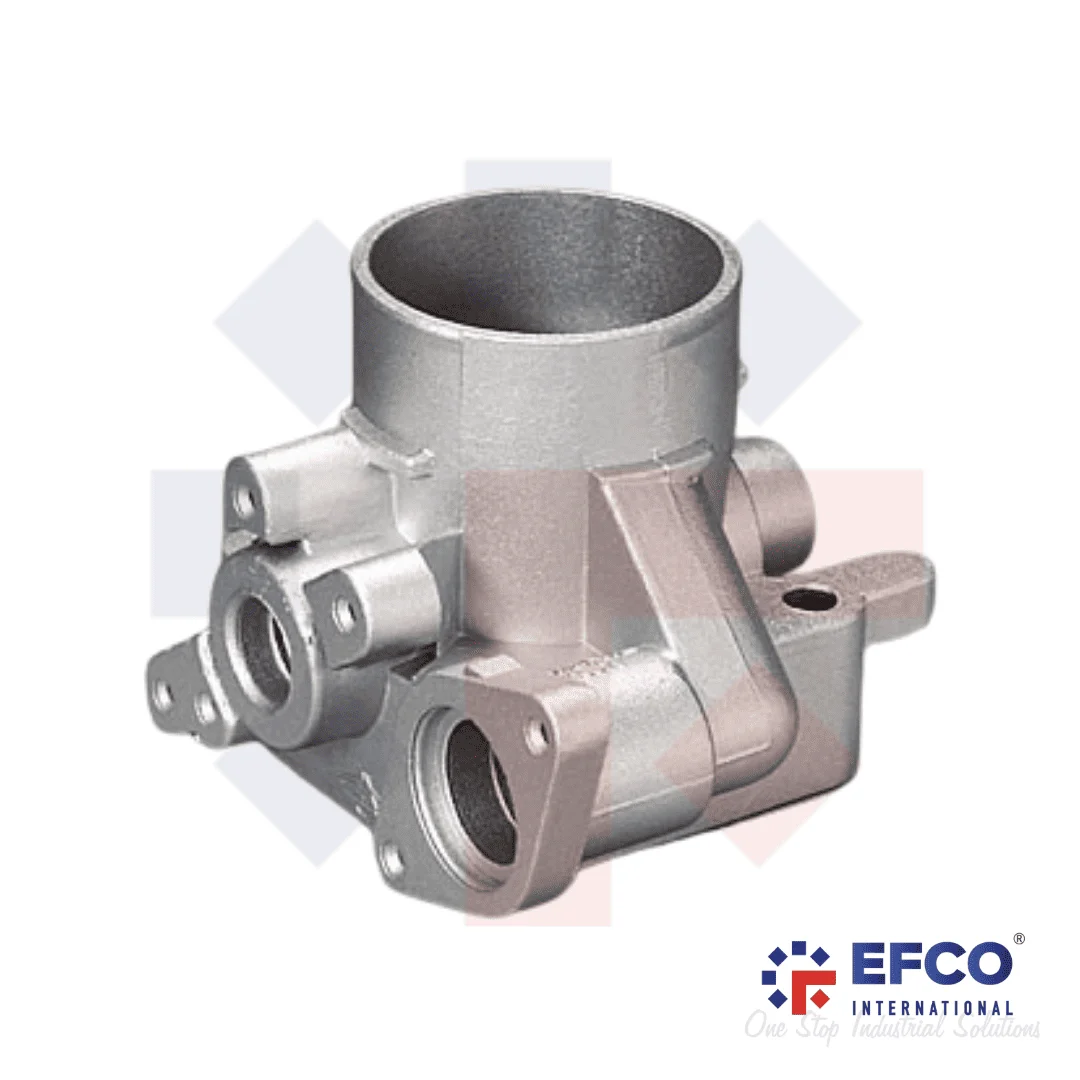

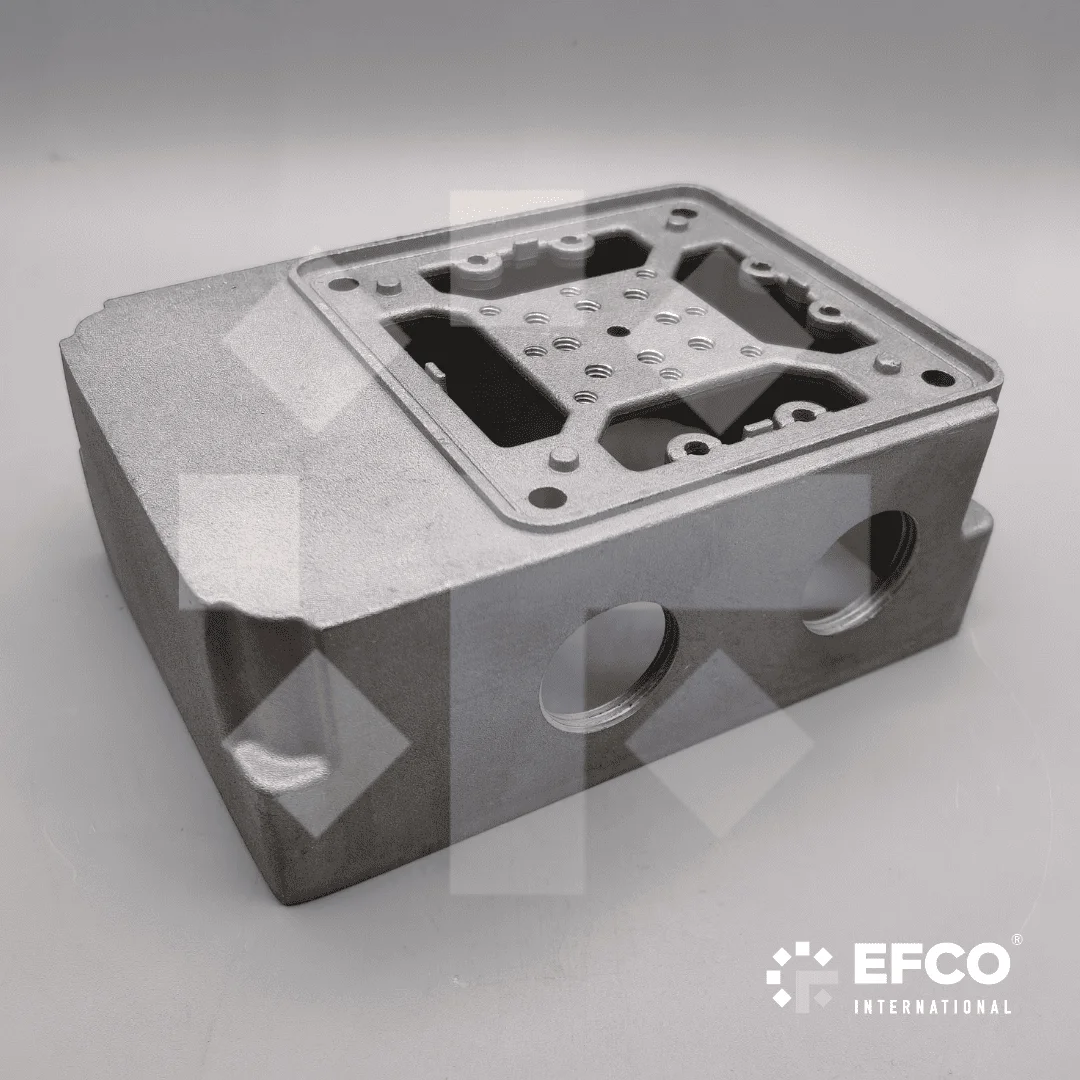

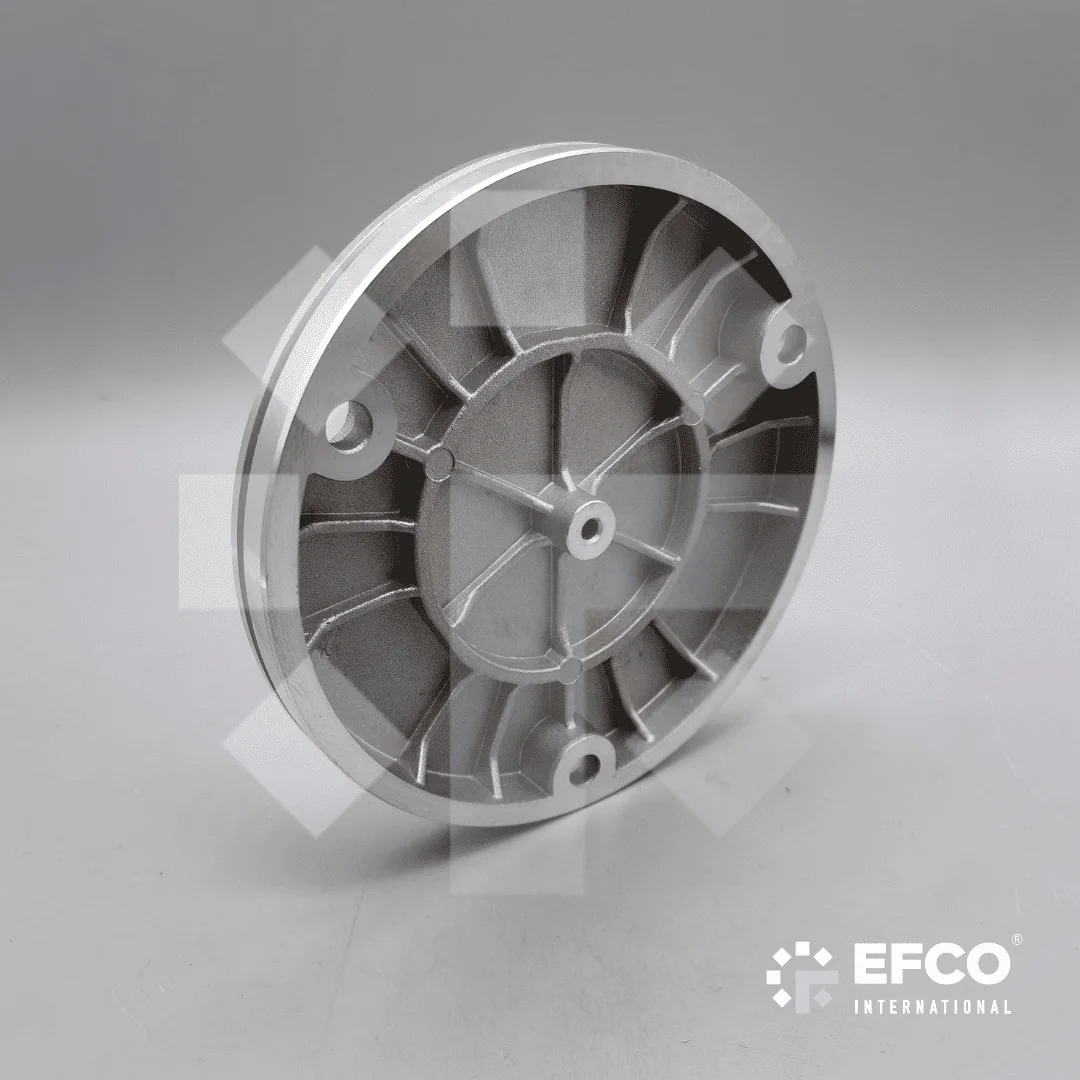

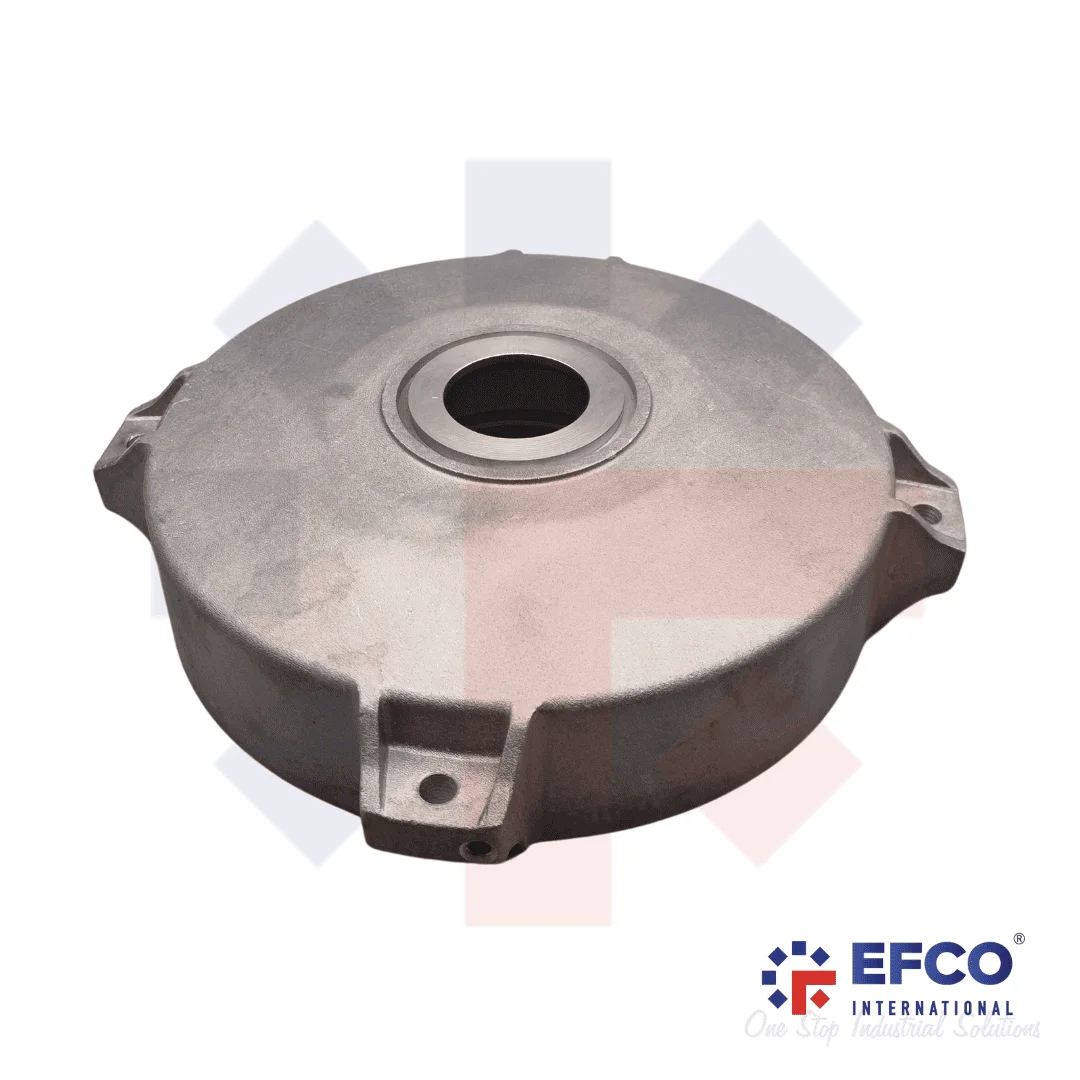

Die Casting

Molten metal is injected into steel molds under high pressure. Provides very precise dimensions, smooth surfaces, and advantages for mass production.

Materials Used: Aluminum alloys (Al-Si, Al-Mg), zinc (Zamak), magnesium

Subtypes: High-pressure die casting, low-pressure die casting, vacuum die casting

Specifications and Tolerances

-

Standards: DIN EN 1706 (Aluminum), ASTM B85 (Aluminum/Zamak)

-

Dimensional tolerance: ISO 8062 CT5 – CT7 (±0.1 – 0.5 mm)

-

Surface roughness: Ra 1.6 – 3.2 µm

Applications

-

Automotive: transmission housings, engine casings, steering and suspension parts

-

Home appliances: washing machine and dishwasher components

-

Electronics: heat sinks, device housings

-

Energy: electric motor and generator housings

-

Consumer products: small Zamak parts

EFCO’s Contribution

-

Determines the most suitable production method and material for the project.

-

Provides certified solutions in compliance with international standards.

-

Ensures quality assurance with dimensional measurement reports and NDT tests.

-

Offers turnkey solutions with delivery time and cost advantages.

We are always ready to help you and answer your questions!